Adjustable supporting arm

A support arm, adjustable technology, applied in the direction of supporting machines, machine tables/brackets, coil springs, etc., can solve the problems of limited difference in cam radius, shortening, and difficult to completely overcome, and achieve the effect of reducing length changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

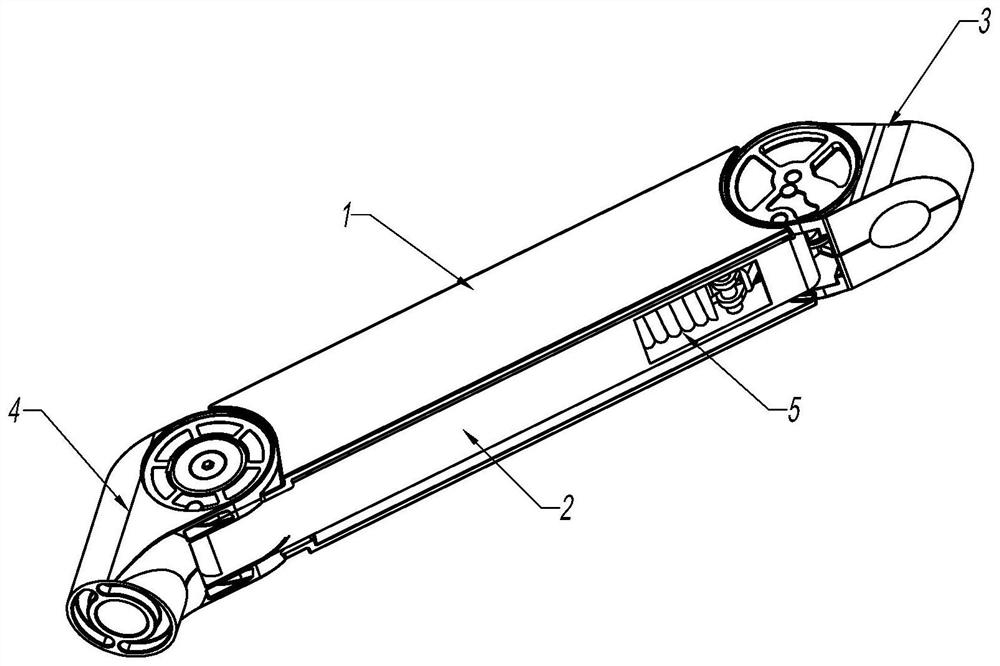

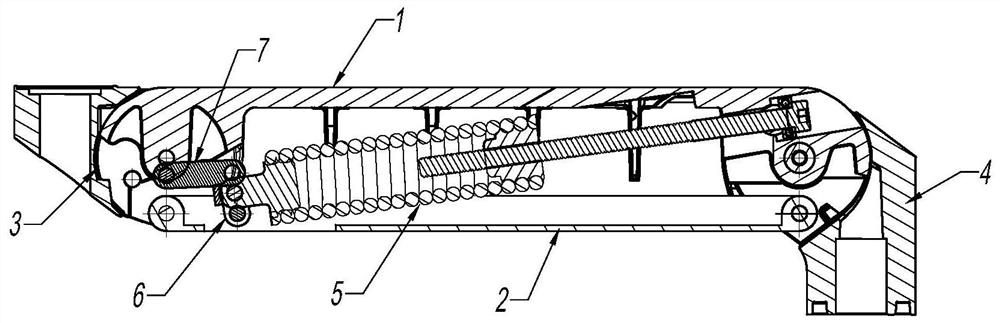

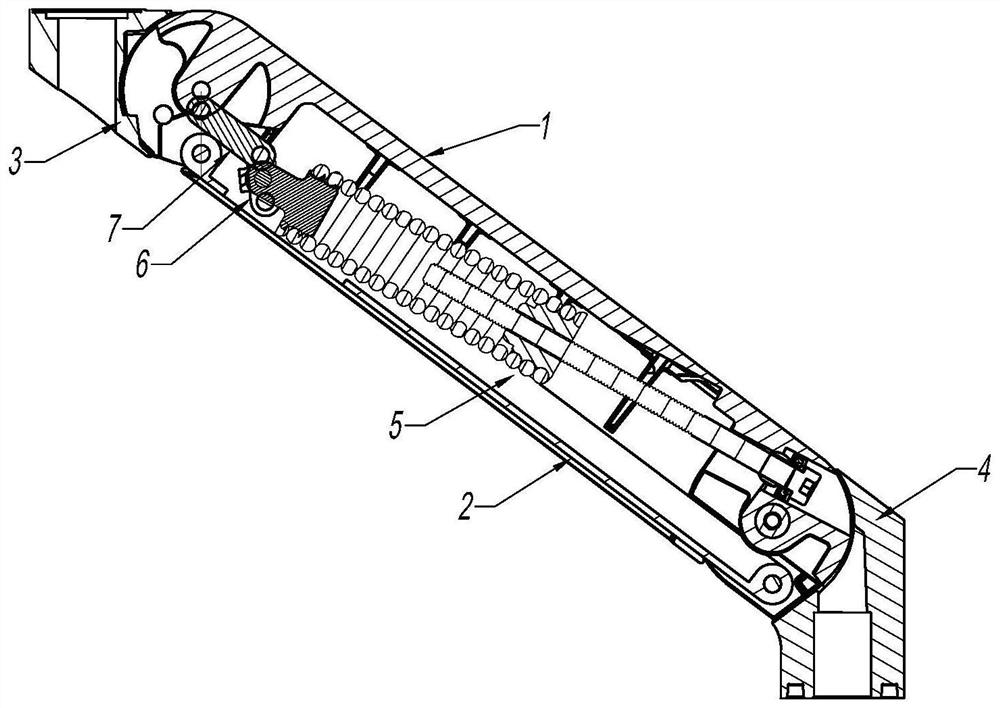

[0037] refer to Figure 1 to Figure 9 , the adjustable support arm includes an upper arm 1, a lower arm 2, a first base body 3, a second base body 4, a spring assembly 5, a first connecting rod 6 and a second connecting rod 7; the upper arm 1, the lower arm 2, The second base body 3 and the second base body 4 are hinged to form a four-bar linkage structure, preferably a parallel four-bar linkage structure. As a support arm used as a monitor stand, the upper arm 1 and the lower arm 2 generally adopt a workpiece with a U-shaped structure in cross-section. Wherein; the spring assembly 5 has a first end 51 and a second end 52, and the first end 51 is preferably movably connected with the upper arm 1 to facilitate the adjustment operation of the spring preload.

[0038] Such as figure 2 , image 3 , Figure 4 and Figure 8 , in this example, one end of the first connecting rod 6 is hinged on the lower arm 2, one end of the second connecting rod 7 is hinged on the first seat 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com