Knitting Element Carrier

A technology of knitting elements and elements, which is applied in the field of knitting element carriers, can solve problems such as high noise, and achieve high longitudinal stiffness and reliable length changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

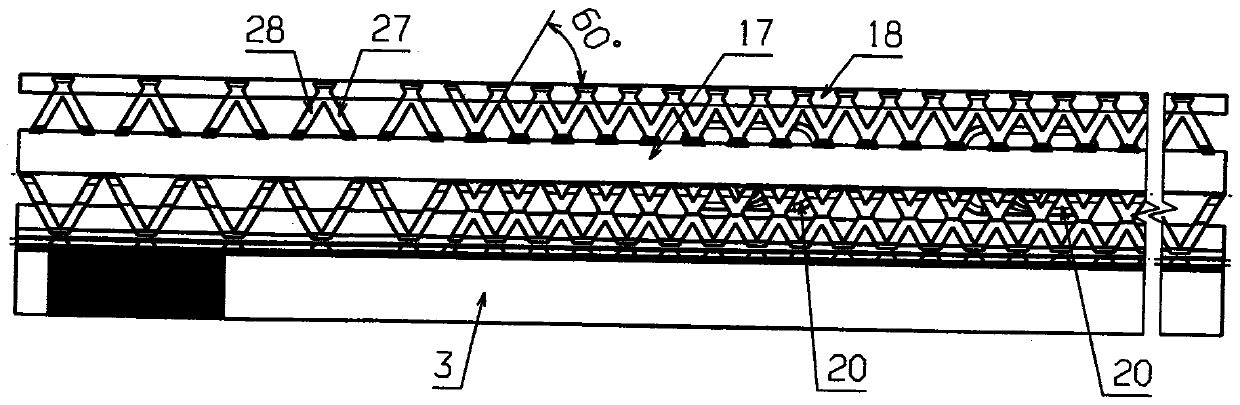

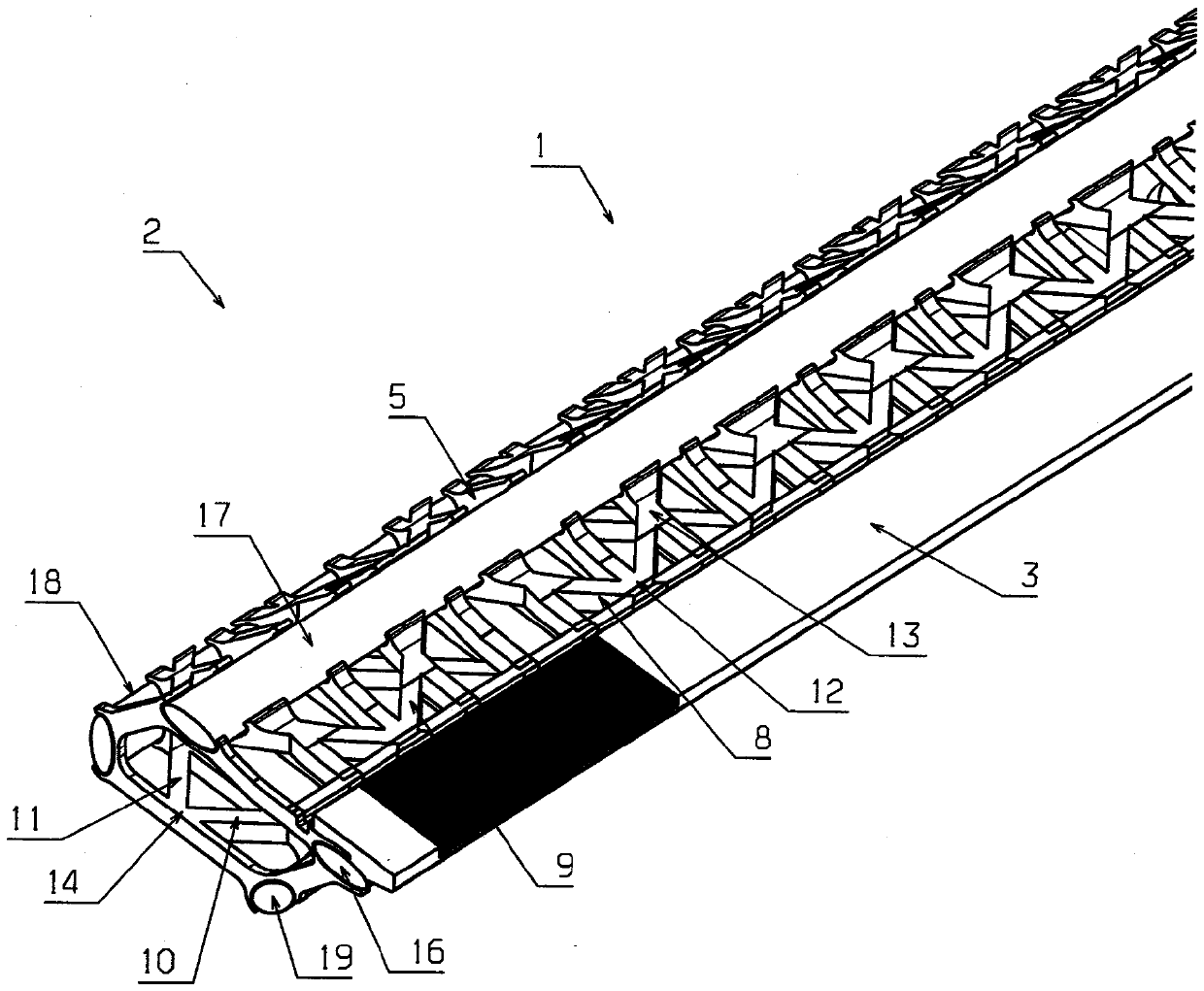

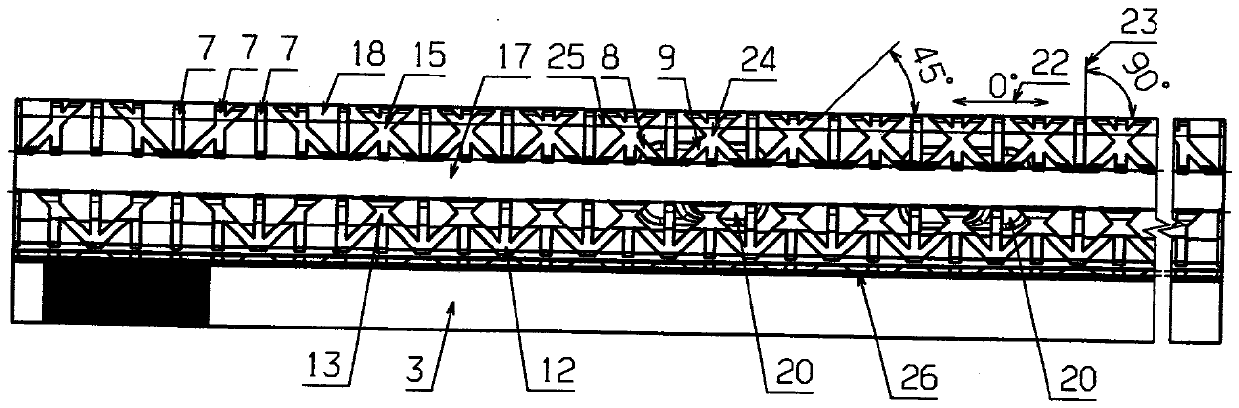

[0036] exist figure 1 and 2 The knitted element carrier 1 shown schematically in FIG. 1 has a main body 2 and a knitted element receptacle 3 . The body 2 is constructed as a skeletal structure, that is to say it has a large number of body bars 4-11. The body rods are connected to each other at nodes 12-15. The main body rods thus form a frame building-like structure so to speak.

[0037] Fiber-reinforced plastic rods 16-19 are attached to the skeleton structure. The plastic rods 16-19 are preferably formed from unidirectional fiber reinforced plastic (CFK) as pultruded rods. The plastic rods have a very high longitudinal stiffness and in practice have no significant thermal expansion in the longitudinal direction. The length of the plastic rods 16 - 19 preferably corresponds to the overall length of the braided element carrier 1 . However, it can also be provided that at least one of the plastic rods 16 - 19 is divided in the longitudinal direction and is thus provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com