Brake and motor

A technology of brakes and brake springs, applied in the direction of brake types, brake actuators, axial brakes, etc., can solve the problems of brake static torque reduction, plane precision deterioration, brake gap unevenness, etc., to increase friction contact area, avoiding the effect of static torque reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

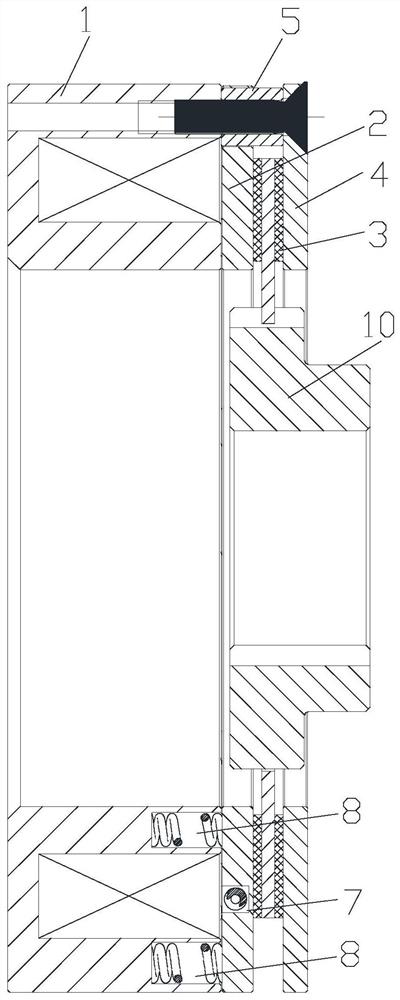

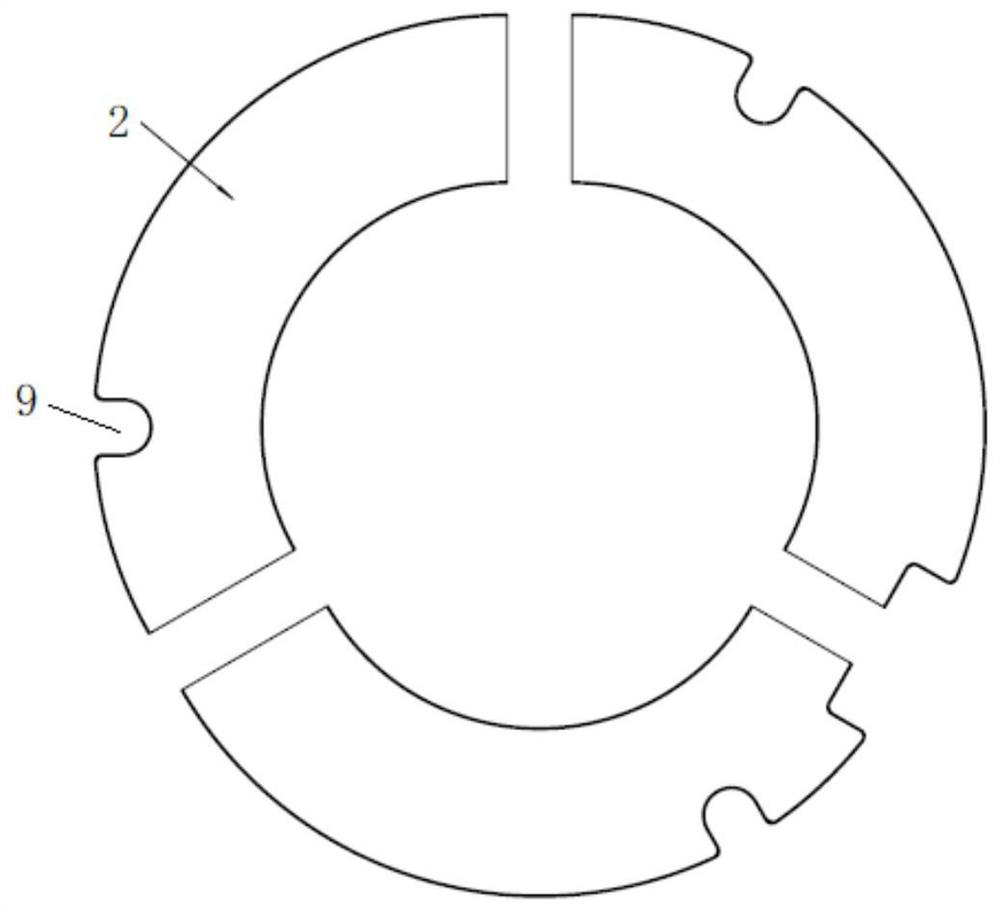

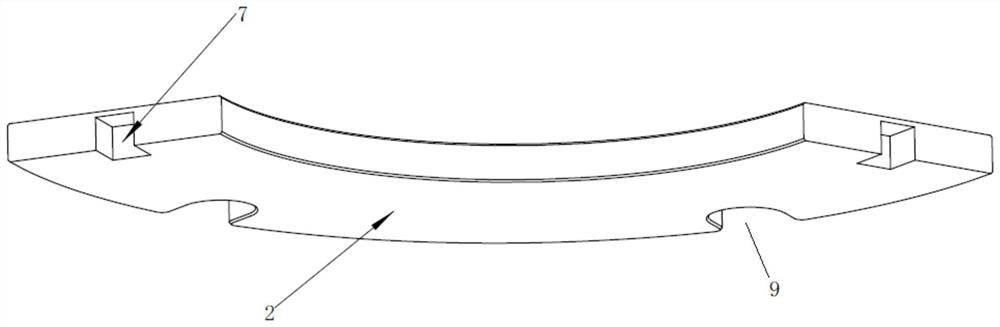

[0030] see in conjunction Figure 1 to Figure 5 As shown, according to the embodiment of the present application, the brake includes a stator core 1, an armature 2, a friction plate 3 and a limiting plate 4 arranged in sequence in the axial direction, and the limiting plate 4 is fixedly connected to the stator core 1 to limit the A guide column 5 is set between the positioning plate 4 and the stator core 1, the armature 2 can be limited by the guide column 5, and slide along the guide column 5, the armature 2 is a block structure, and the adjacent blocks can Relative displacement in the axial direction. The brake also includes a hub 10, which forms a circumferential transmission between the hub 10 and the rotating shaft. The friction plate 3 cooperates with the hub 10. By locking the hub 10 or unlocking the hub 10, the motor brake or brake is released.

[0031] In the brake of this application, the armature 2 adopts a block structure, so that the armature 2 can be changed int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com