End-expanded recyclable fence and construction method thereof

A circular and enclosure technology, applied in the direction of fences, building types, buildings, etc., can solve the problems of increased space occupied by structures, heavy weight of concrete components, and long construction period, etc., to achieve convenient transportation and storage, processing and replenishment Convenience, convenient organization and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

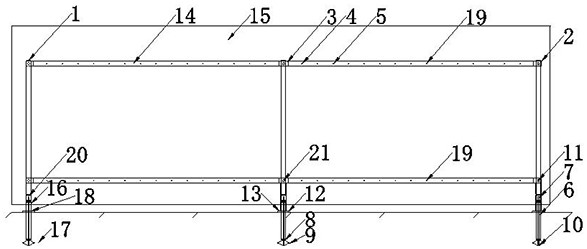

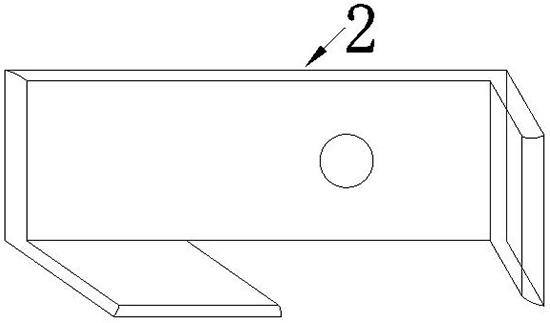

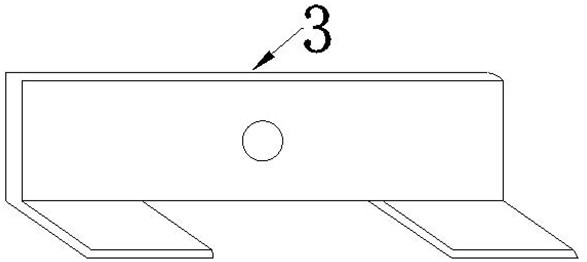

[0040] Example: such as Figure 1-Figure 9 As shown, the present invention includes a column 1, a column foundation 6, an anti-settling backing plate 12, a round place pipe 7, fixtures 2 and 3, a transverse square pipe 14, and a retaining panel 15; the column 1 and the column foundation 6 are in the same The positions are arranged up and down, and are connected as a whole by the Tianyuan local pipe 7 on the ground; as Figure 9 As shown, the upper half of the column foundation 6 is a round steel pipe 16, and the lower half is provided with an expansion device 17; as Figure 8 As shown, the anti-settling backing plate 12 is set on the round steel pipe 16 of the upper half of the column foundation 6, and the anti-settling steel column 13 is inserted into the bolt hole 18 on the round steel pipe 16 to fix the anti-settling backing plate 12 to prevent Settlement and inclination after the construction process and enclosure completion; the expansion device 17 is to expand the end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com