Drafting process finishing method for spinning 5tex fibers by using recycled polyester fibers

A technology for recycling polyester and polyester fiber, which is applied in the field of polyester fiber, can solve problems such as non-conformity, polyester fiber bifurcation, and polyester fiber breakage, so as to improve the pass rate, reduce breakage and fork, The effect of reducing damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

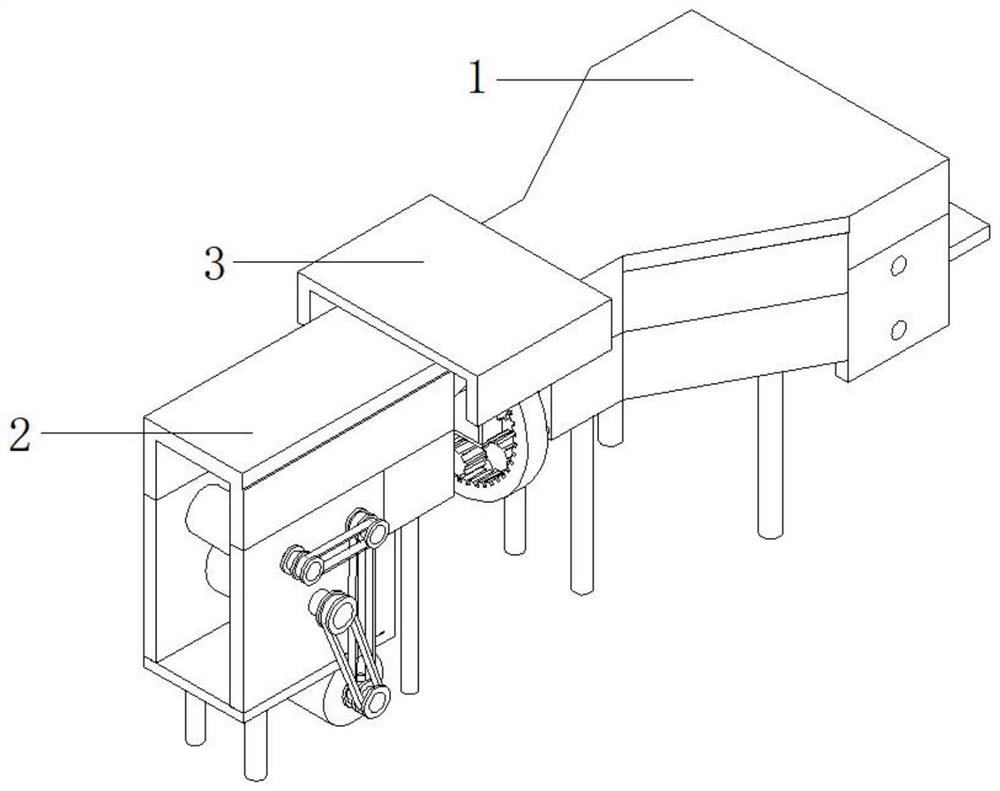

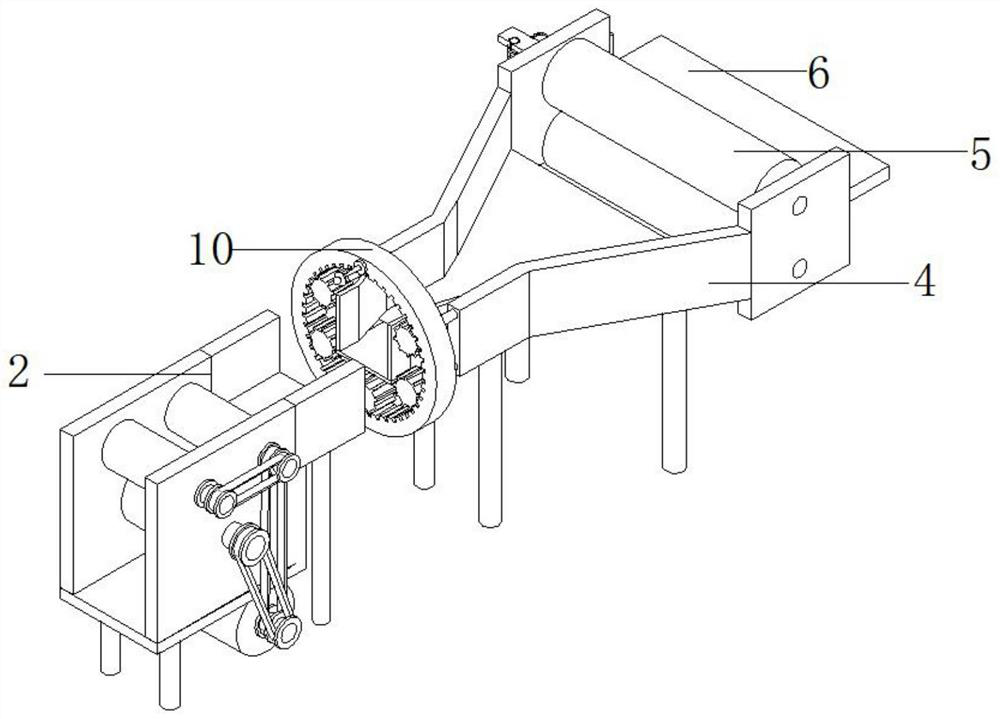

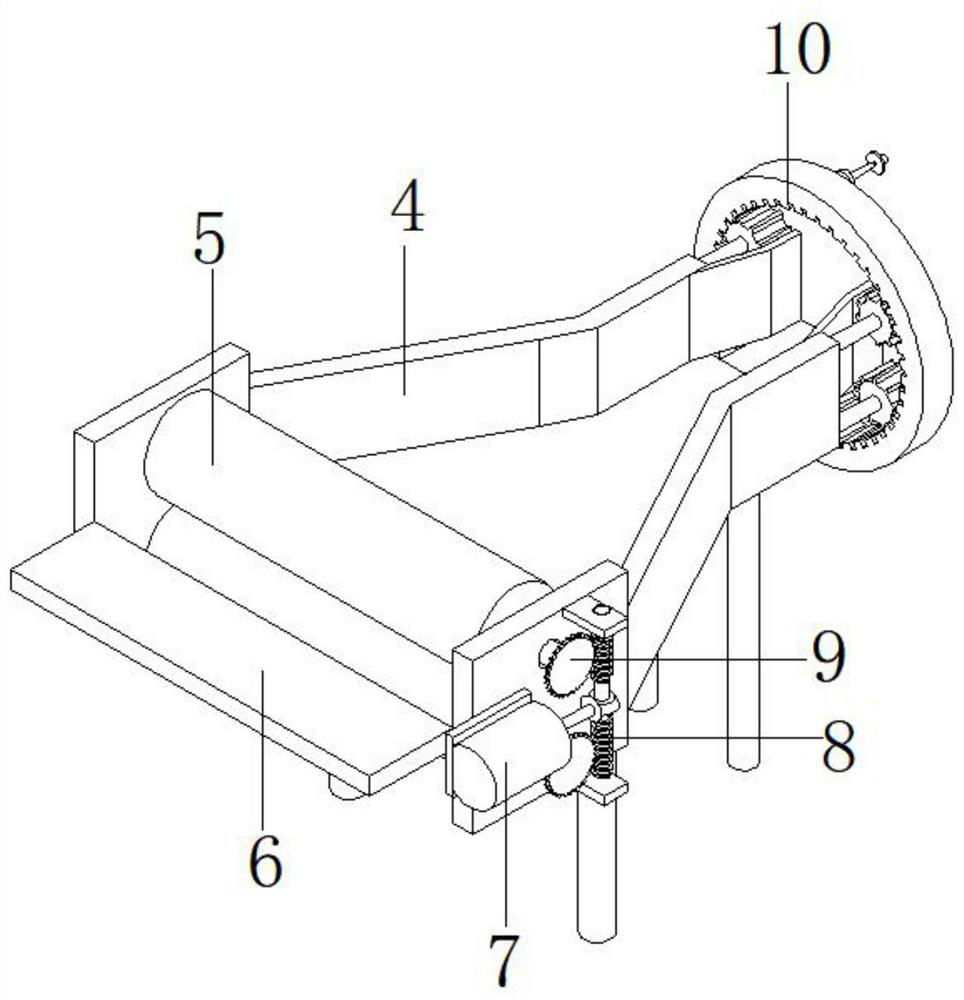

[0024] refer to Figure 1-6 , a drafting process utilizing recycled polyester fibers to spin 5tex fibers, comprising a drafting device required for the drafting process, said drafting device comprising an extruding structure 1, a drafting device located at one end of the extruding structure 1 The structure 2 and the cover plate 3 placed between the extrusion structure 1 and the drafting structure 2, the extrusion structure 1 includes a hopper 4, an extrusion roller 5 rotatably connected to one end of the hopper 4, welded to the outer wall of one end of the hopper 4 The discharge plate 6 and the closing structure 10 installed at one end of the hopper 4, the first moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com