High-strength wrought aluminum alloy and production method thereof

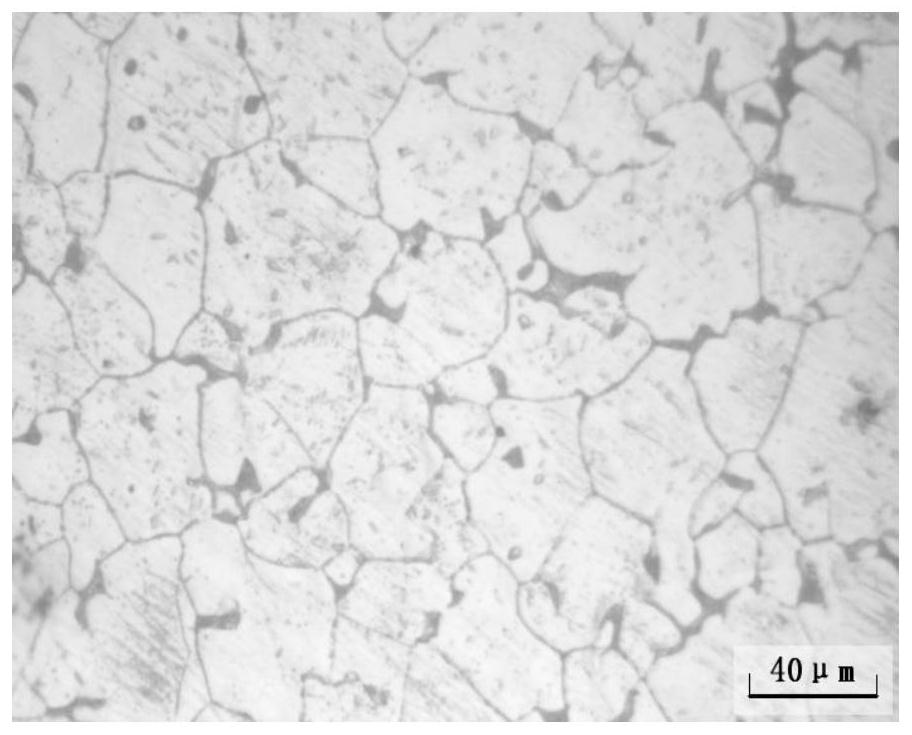

A deformed aluminum alloy, high-strength technology, applied in the field of alloys, to achieve stable performance, improve mechanical properties, and small grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A high-strength deformed aluminum alloy, composed of the following components in weight percentage: Mg0.5%; Si0.3%; Gd0.5%; Zr0.3%; the balance is Al and unavoidable impurities, wherein the impurity elements The content is less than 0.02%.

[0032] The above-mentioned high-strength deformed aluminum alloy is prepared by the following process:

[0033] S1: Weigh 940kg of industrial pure Al, 5kg of industrial pure Mg, 25kg of Al-20Gd master alloy, 15kg of Al-20Si master alloy and 15kg of Al-20Zr master alloy according to the proportions mentioned above.

[0034] S2: Heat the reactor, firstly heat the reactor to 700°C and add pure Al until the pure Al is completely melted, then add industrial pure Mg until it is completely melted, and when the temperature continues to rise to 720°C, the Al-20Gd master alloy Add the Al-20Si master alloy into the melt until it is completely melted, continue to raise the temperature of the reactor to 780°C, and then add the Al-20Zr master al...

Embodiment 2

[0041] A high-strength deformed aluminum alloy, composed of the following components in weight percentage: Mg0.5%; Si0.3%; Gd0.5%; Zr0.3%; the balance is Al and unavoidable impurities, wherein the impurity elements The content is less than 0.02%.

[0042] The above-mentioned high-strength deformed aluminum alloy is prepared by the following process:

[0043] S1: Weigh 940kg of industrial pure Al, 5kg of industrial pure Mg, 25kg of Al-20Gd master alloy, 15kg of Al-20Si master alloy and 15kg of Al-20Zr master alloy according to the proportions mentioned above.

[0044] S2: Heat the reactor, firstly heat the reactor to 700°C and add pure Al until the pure Al is completely melted, then add industrial pure Mg until it is completely melted, and when the temperature continues to rise to 720°C, the Al-20Gd master alloy Add the Al-20Si master alloy into the melt until it is completely melted, continue to raise the temperature of the reactor to 780°C, and then add the Al-20Zr master al...

Embodiment 3

[0051] A high-strength wrought aluminum alloy consisting of the following components by weight percentage: Mg0.8%, Si0.6%, Gd0.8%; Zr0.4%; the balance is Al and unavoidable impurities, of which impurity elements The content is less than 0.02%.

[0052] The preparation method is the same as that of Example 2, wherein 902 kg of industrial pure Al, 8 kg of industrial pure Mg, 40 kg of Al-20Gd master alloy, 30 kg of Al-20Si master alloy and 20 kg of Al-20Zr master alloy are added.

[0053] The aluminum alloy prepared above was subjected to a tensile test at room temperature. The tensile machine was a Zwick BTC-Z100 electronic universal material testing machine, and the tensile test rate was 0.5 mm / min. The tensile strength of the obtained alloy at room temperature is 562MPa, the yield strength is 514MPa, and the elongation is 11.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com