Method for preparing low-shrinkage concrete from bagasse ash

A technology of bagasse and concrete, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of easy cracking of concrete, increase of concrete self-shrinkage, etc., achieve resource utilization and reduce carbon dioxide emissions , the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] (1) Bagasse and rice husk are recycled;

[0029] (2) Calcining and grinding the recycled bagasse and rice husk, the calcination temperature is 600°C, 650°C, 700°C, and the grinding time is 1.5, 2, 2.5 hours;

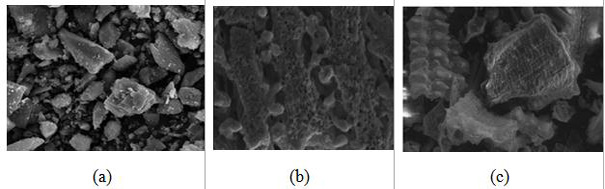

[0030] (3) test the chemical composition and physical properties of bagasse ash and rice husk ash, the results are shown in Table 1 and Table 2, and the scanning electron micrographs of cement, bagasse ash and rice husk ash are shown in figure 1 ;

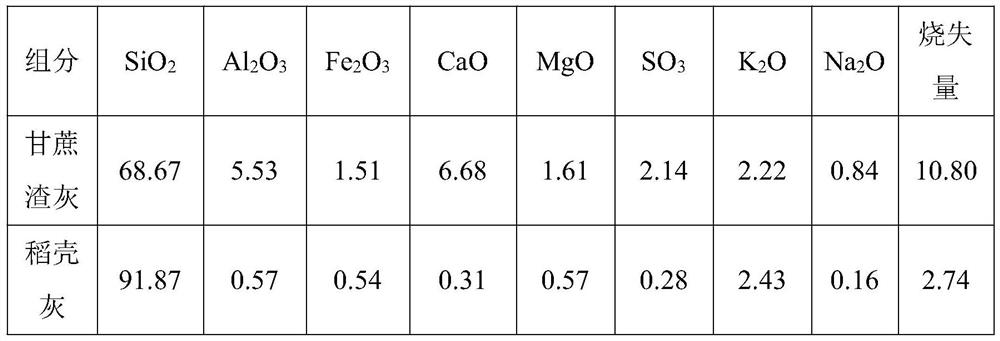

[0031] The chemical composition (%) of table 1 bagasse ash and rice husk ash

[0032]

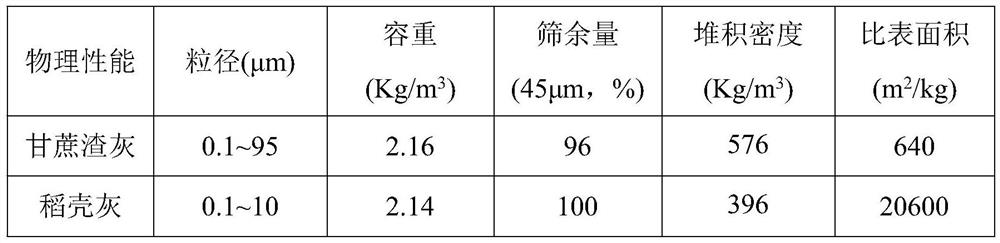

[0033] Table 2 The physical properties of bagasse ash and rice husk ash

[0034]

[0035] (4) The calcination temperature is respectively 600, 650, 700 ℃, and the bagasse ash that the grinding time is respectively 1.5, 2, 2.5 hours replaces cement according to 20wt%, gets 240 parts by weight of cement, 60 parts by weight of bagasse ash and rice Shell ash, 150 parts by weight of water, 780 parts by weight of sand and 1170 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com