Automatic stamping machine

An automatic stamping machine and seal technology, applied in mechanical equipment, vibration suppression adjustment, printing, etc., to achieve the effect of ensuring clarity, convenient use, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

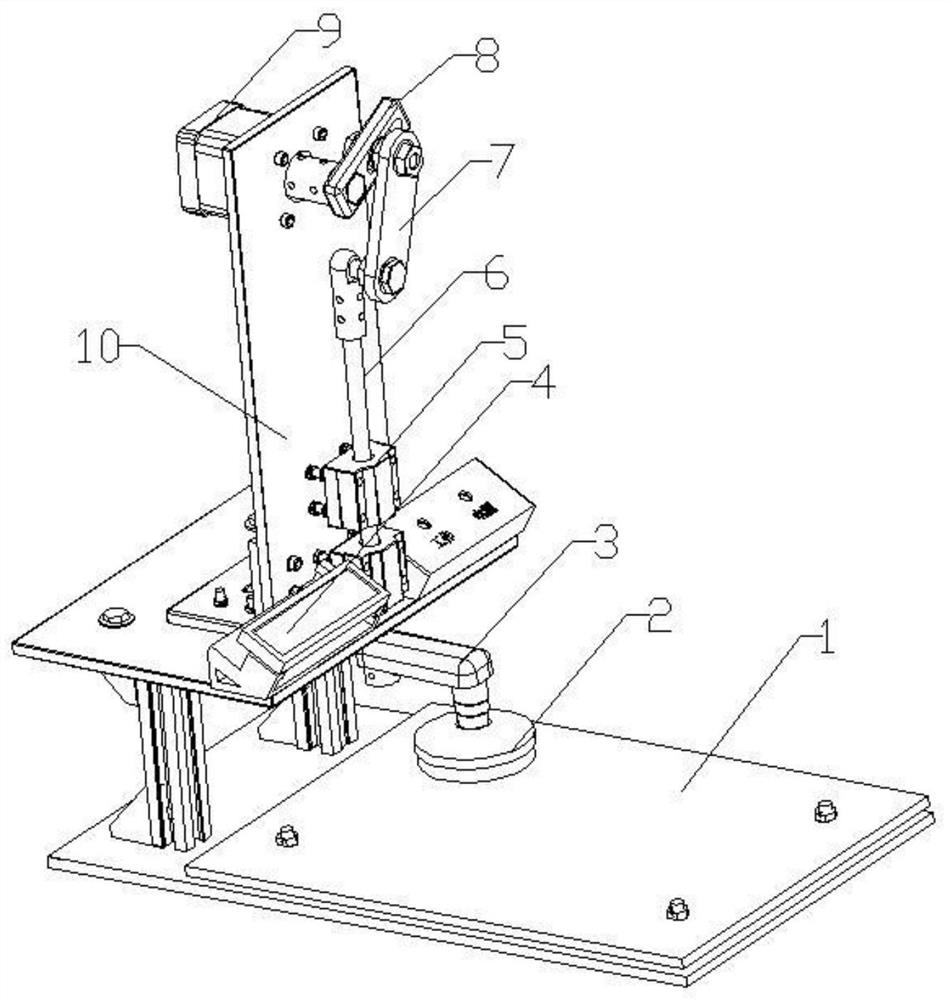

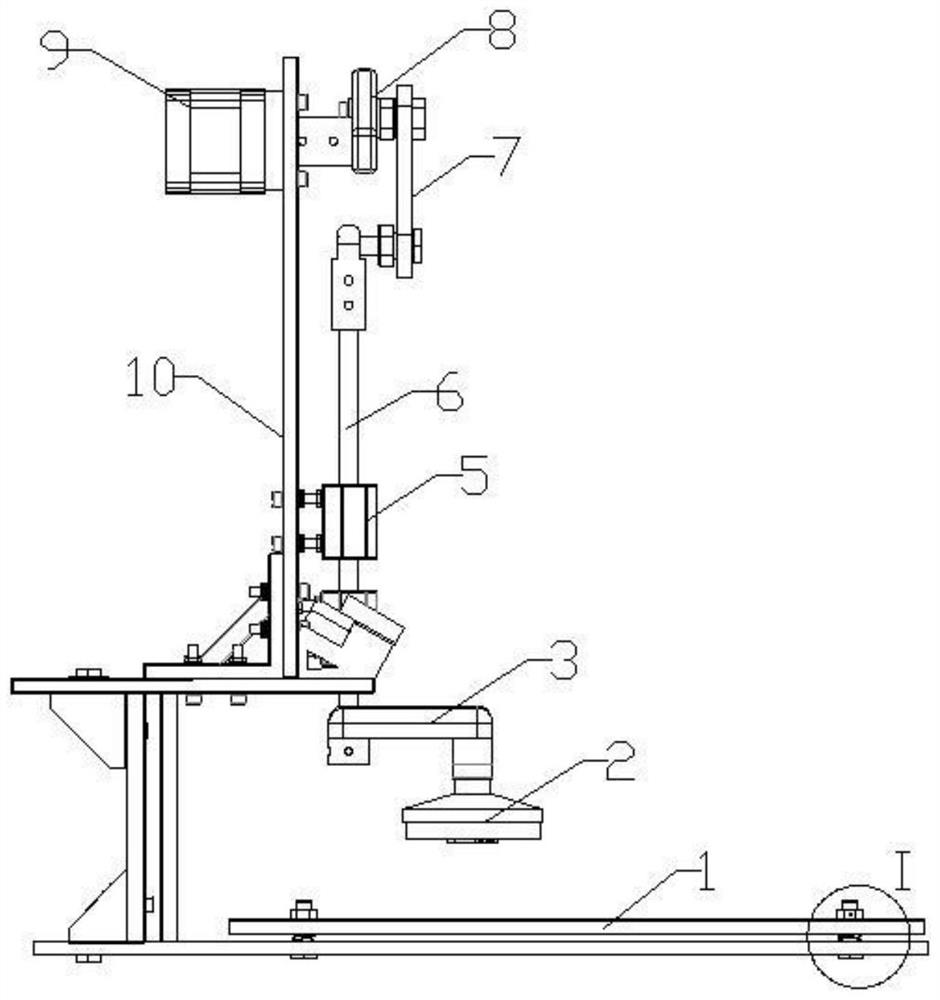

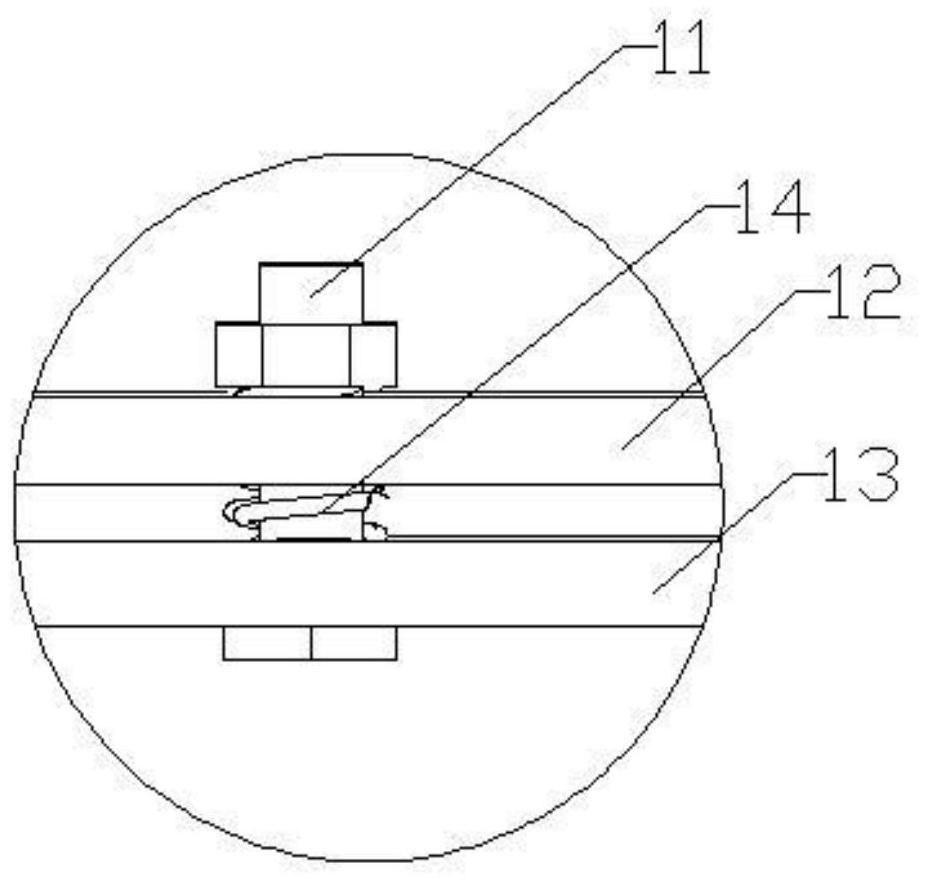

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] Such as Figure 1 to Figure 4 As shown, the automatic stamping machine of the present invention includes a frame 10, a rotating member 9, an intermediate rod 7, and a connecting rod 6. The rotating member 9 is arranged on the frame 10, and one end of the intermediate rod 7 is connected to the output shaft of the rotating member 9 , the other end is hinged with the connecting rod 6, the other end of the connecting rod 6 can be connected with the stamp 2, and the rotary member 9 is turned so that the stamp 2 can move up and down. Those skilled in the art can understand that the frame 10 of the device is mainly used to support the whole device, so its structure can be determined according to the implementation requirements. The rotating member 9 is installed on the frame 10, and the rotating member 9 mainly provides a source of power, so the rotating member 9 may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com