Taste-masking capsaicin particles and preparation method thereof

A technology of capsaicin and granules, which is applied in the directions of oil-containing food ingredients, natural extract-containing food ingredients, food forming, etc., can solve the problems of limited effect of capsaicin on irritant mitigation, large particle size of microspheres, affecting product application, etc. , to achieve the effect of slowing oral irritation, uniform particle size and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

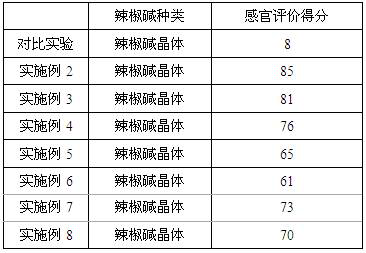

Examples

Embodiment 1

[0027] The present embodiment provides a taste-masking capsaicin granule, comprising a granular material and a coating layer, the coating layer is coated on the granular material, and the granular material is composed of the following components in weight percentage: capsaicin 1- 30%, 70-95% of auxiliary materials and 0.5-3% of adhesives.

[0028] The present invention granulates the raw material of capsaicin, improves the granule state of the raw material of capsaicin to make it easy to coat, and slows down the oral irritation of capsaicin to a certain extent, and then coats the capsaicin granules, and the capsaicin granules The surface is coated with one or more coating layers to isolate capsaicin from direct contact with the human body, so that it can achieve an excellent taste-masking effect and greatly reduce the oral irritation of capsaicin.

Embodiment 2

[0030] On the basis of Example 1, this embodiment provides a taste-masking capsaicin granule, including a granular material and a coating layer, the coating layer is coated on the granular material, and the granular material is composed of the following mass: Composition: capsaicin 10g, auxiliary material 90g and binder 1.5g.

[0031] Preparation Process:

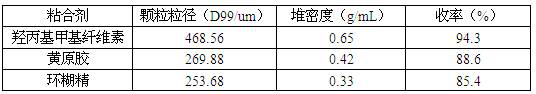

[0032] Accurately weigh 10g capsaicin, 90g auxiliary materials, and 1.5g binder. The binder was prepared into 50 g of hydroxypropyl methylcellulose solution with a volume percentage of 3%, and after mixing evenly, extrusion spheronization was carried out, and then dried in a fluidized bed at 55°C. Extrusion spheronization granulation process parameters: extrusion frequency 50Hz, spheronization speed 1500rpm, spheronization time 200s. Take 600g of 5% mass concentration of hydroxypropyl methylcellulose solution as a coating solution, coat the dried capsaicin granules, and dry them in a fluidized bed at 55°C after coating to...

Embodiment 3

[0041] On the basis of Example 1, this embodiment provides a taste-masking capsaicin granule, including a granular material and a coating layer, the coating layer is coated on the granular material, and the granular material is composed of the following mass: Composition: capsaicin 20g, auxiliary material 80g and binder 1.8g.

[0042] Preparation Process:

[0043] Accurately weigh 20g of capsaicin, 80g of auxiliary materials, and 1.8g of adhesive to prepare 60g of a solution with a concentration of 3% by weight. After mixing evenly, carry out extrusion spheronization and granulation, and then dry in a fluidized bed at 55°C. Extrusion spheronization granulation process parameters: extrusion frequency 50Hz, spheronization speed 1500rpm, spheronization time 200s. Take 800g of 5% mass concentration of hydroxypropyl methylcellulose solution as a coating solution, coat the dried capsaicin granules, and dry them in a fluidized bed at 55°C after coating to obtain a taste-masking prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com