Wireless temperature measurement system for heat storage element in rotor of rotary air preheater

An air preheater and wireless temperature measurement technology, which is applied in the direction of thermometers, thermometer parts, and instruments that use electrical/magnetic components directly sensitive to heat. Accurately measure the temperature of the internal heat storage element, the fouling and blockage of the air preheater, etc., to achieve the effect of easy real-time control, easy inspection, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with legend the present invention is further illustrated and illustrated:

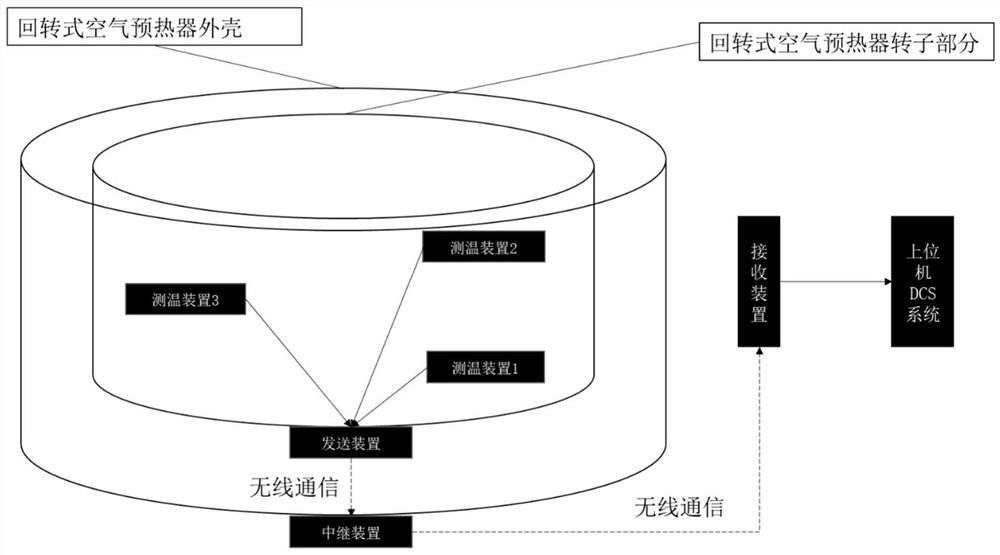

[0033] Such as figure 1 As shown, the present invention provides a wireless temperature measurement system for heat storage elements inside the rotor of a rotary air preheater. The system includes a temperature measurement device, a sending device, a relay device, a receiving device and a host computer.

[0034] The temperature measuring device is installed on the surface of the heat storage element to directly measure the temperature of the heat storage element, and transmit it to the sending device by way of wired transmission.

[0035] The sending device is arranged at the end of the rotor of the air preheater, and is used to receive the temperature signal transmitted by the temperature measuring device, process it and send it to the relay device.

[0036] The relay device is arranged on the shell of the air preheater and runs through the shell. Its function is to overco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com