Method for preparing clean fuel through co-hydrothermal carbonization of sludge and coal slime

A technology of hydrothermal carbonization and clean fuel, applied in the direction of fuel, waste fuel, biofuel, etc., can solve the problems of ineffective improvement of sludge dehydration efficiency, reduction of cement hydrothermal carbon quality, and carbon content reduction, to achieve Realize the effects of efficient clean utilization, easy removal, improved calorific value and desulfurization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing clean fuel by co-hydrothermal carbonization of sludge and coal slime, comprising the steps of:

[0025] Sludge (Taiyuan City Jinyang Sewage Treatment Plant), and coal slime (Xiangyuan County Honglu Washing Coal Co., Ltd.), sludge and coal slime according to different mass ratios (respectively 3:7, 5:5, 7 : 3) mix and put into hydrothermal reaction kettle respectively, wherein the moisture content of sludge is 85%, and the moisture content of coal slime is 35%. The reaction temperature of hydrothermal carbonization is 240°C and kept for 2 hours. After the reaction is completed, after the reaction kettle is cooled to room temperature, the carbon slurry in the reaction kettle is dehydrated by a micro plate and frame filter press.

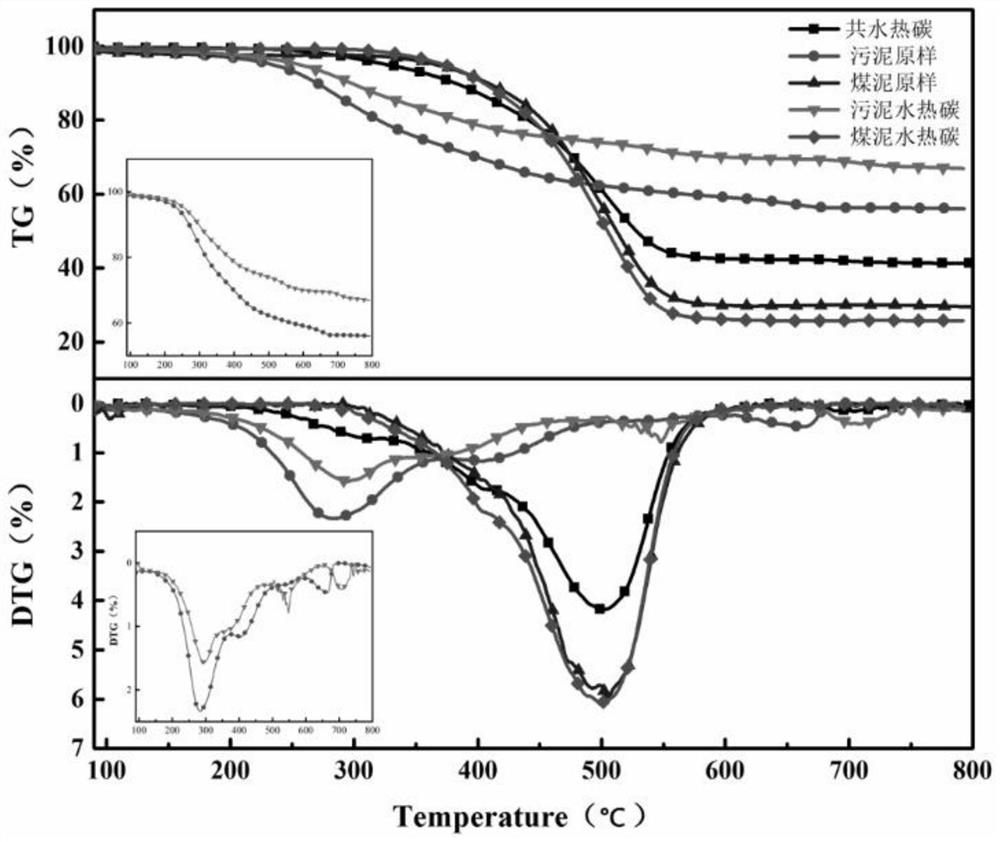

[0026] Result analysis: In order to study the synergistic effect of co-hydrothermal carbonization of sludge and coal slime, the measured data were compared with the theoretical value of physical mixing assuming separate hy...

Embodiment 2

[0036] A method for preparing clean fuel by co-hydrothermal carbonization of sludge and coal slime, comprising the steps of:

[0037] Put 1kg domestic sludge (Jinyang Sewage Treatment Plant, Taiyuan City) and 1kg coal slime (Honglu Washing Coal Co., Ltd., Xiangyuan County) into the hydrothermal reaction kettle, wherein the moisture content of the sludge is 80%, and the coal slime The water content is 35%. The reaction temperature of hydrothermal carbonization is 280°C and kept for 1 hour. After the reaction is completed, after the reaction kettle is cooled to room temperature, the carbon slurry in the reaction kettle is dehydrated through a micro plate and frame filter.

[0038] Result analysis: after coal slime and sludge are processed by the inventive method, its result is as shown in table 2:

[0039] Table 2 Theoretical calorific value, sulfur content and synergy coefficient of sludge, coal slime and their co-water thermal carbon

[0040]

[0041] According to the above ...

Embodiment 3

[0043] A method for preparing clean fuel by co-hydrothermal carbonization of sludge and coal slime, comprising the steps of:

[0044] Put 1kg of domestic sludge (Jinyang Sewage Treatment Plant, Taiyuan City) into a hydrothermal reaction kettle, wherein the sludge has a moisture content of 85%, add an appropriate amount of citric acid to adjust the pH to 3-4, and the reaction temperature of hydrothermal carbonization is Keep at 240°C for 1 hour. After the reaction is completed, after the reaction kettle is cooled to room temperature, the carbon slurry in the reaction kettle is dehydrated through a micro plate and frame filter press.

[0045] Result analysis: After coal slime and sludge are treated by the method of the present invention, the results are shown in Table 3. After adding citric acid for assistance, the calorific value of hydrothermal carbon is obviously improved, and this is because acidic conditions can promote the original hydrolysis, The carbonization process all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com