Bio-ink 3D printing straight line element process parameter optimization method

A technology of process parameter optimization and 3D printing, applied in the direction of processing data acquisition/processing, additive processing, manufacturing auxiliary devices, etc., can solve problems such as difficulty in achieving optimal quality and uneven quality of linear elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

[0067] Such as figure 1 As shown, the process parameter optimization method of the bio-ink 3D printing linear elements, the steps are as follows:

[0068] S1. Through the analysis of the 3D printing process, determine the process parameters of the bio-ink 3D printing linear elements;

[0069] Specifically, the specific operation of the step S1 is as follows:

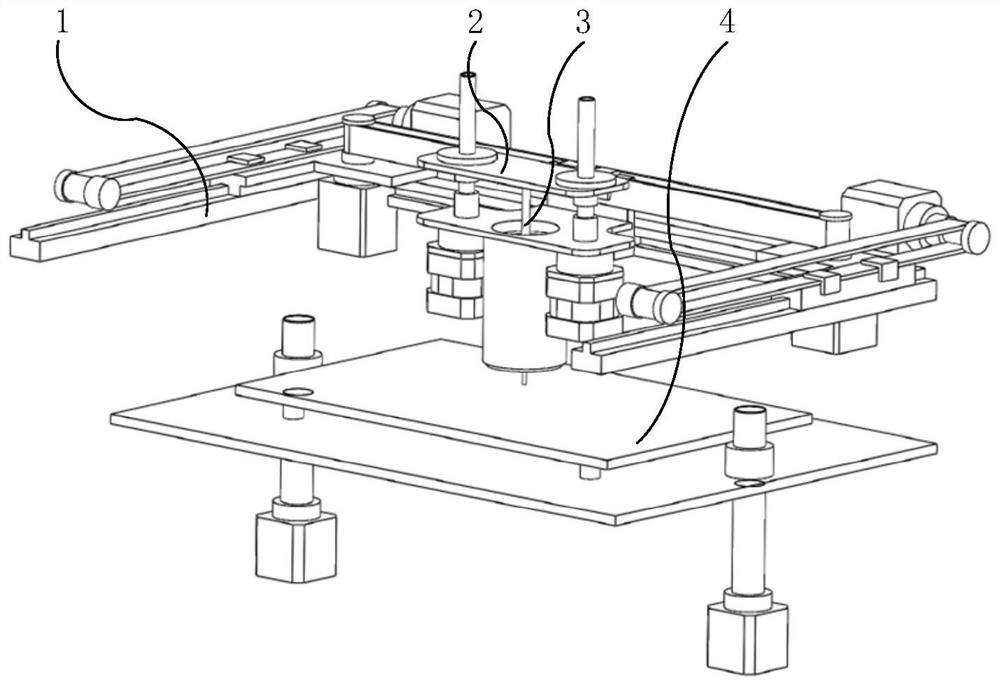

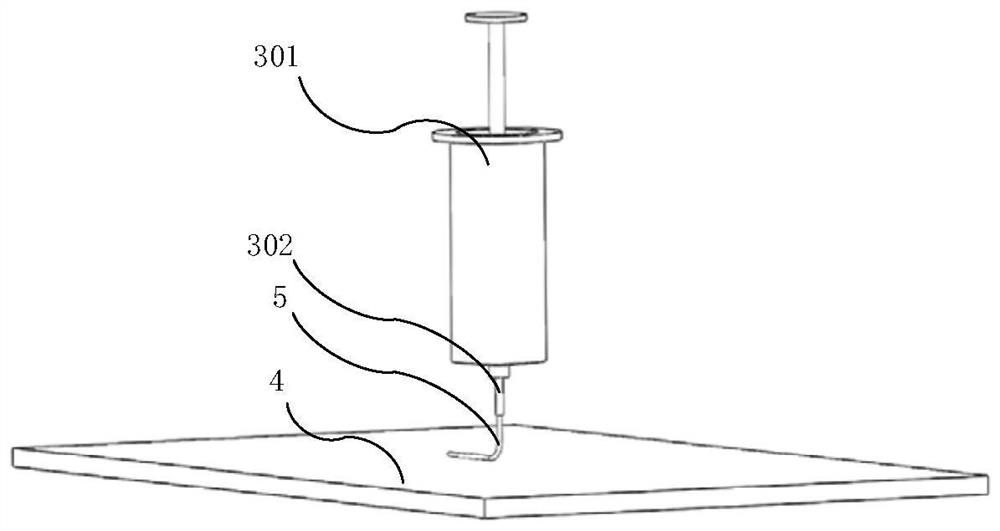

[0070] use as figure 2 The extrusion type 3D printer shown carries out the linear element printing of bio-ink;, wherein, such as figure 2 and image 3 As shown, the extrusion 3D printer includes: a three-axis motion platform 1, a piston 2, an extrusion device 3, a substrate 4 and a bioink 5; the extrusion device 3 includes a needle tube 301 and a nozzle 302;

[0071] The technological process of 3D printing linear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com