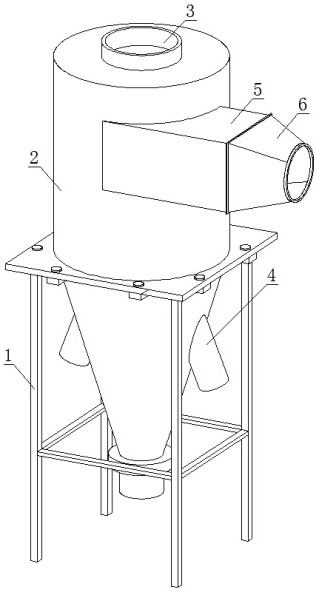

Classified cyclone dust collection device with multi-stage vortex tube combination and its implementation method

A cyclone dust collection and vortex tube technology, which is applied in the separation method, the cyclone device, and the device whose axial direction of the cyclone remains unchanged, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

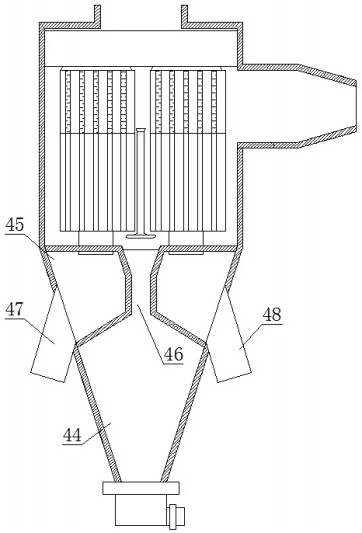

[0043] In order to further and better explain the above-mentioned embodiments, the present invention also provides an embodiment, an implementation method of a classified cyclone dust collection device with a combination of multi-stage vortex tubes, comprising the following steps:

[0044] Step 1: The dust collector 2 is externally connected to a fan, and the fan is turned on to work, and the dust and gas are discharged into the interior of the dust collector 2 through the dust inlet 6;

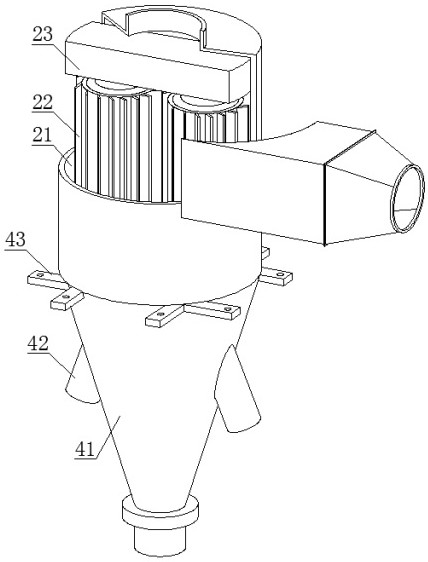

[0045] Step 2: Turn on the motor to work, the motor drives the driving wheel 22114 to rotate through the coupling 22115, so that the central shaft 22111 can rotate, and the central shaft 22111 is fixedly connected with the outer cover 2212 through the connecting plate 22112, which is convenient for the outer cover 2212 and the first worm rod 221 Rotate, the outer surface of the driving wheel 22114 is provided with a belt piece 22116, and the side of the belt piece 22116 away from the driving w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com