High-flux low-molecular-retention hollow fiber ultrafiltration membrane and preparation method thereof

An ultrafiltration membrane and hollow technology, applied in the field of hollow fiber ultrafiltration membrane preparation, can solve the problems of easily polluted membrane production process, low water flux of ultrafiltration membrane, poor hydrophilicity, etc., to increase pollution resistance, good Low molecular interception effect, effect of reducing adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

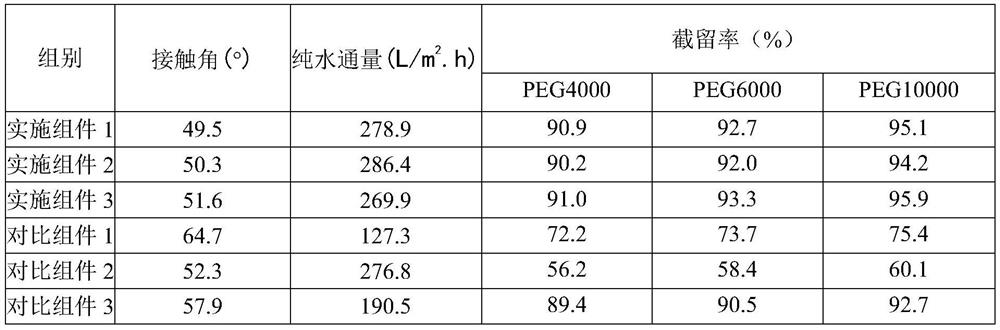

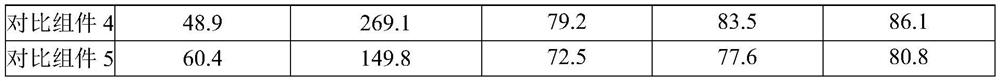

Examples

Embodiment 1

[0041] The specific preparation process of the hollow fiber ultrafiltration membrane is operated as follows:

[0042] Step 1: Dissolve the mass fraction of 15 parts of polyether sulfone in N-methylpyrrol, form a homogeneous solution, and 20 parts of a acetyl chloride, a mass fraction of 5 parts of aluminum In N-methylpyrrol, in an 80 ° C, poured into a homogeneous solution, stirred, and the reaction was refluxed for 1 h. The product was washed with secondary distilled water, dried under the oven at 120 ° C for 12 h, and was allowed to give a carboxyl modified polyether sulfone, and a polysulfone resin having a mass fraction was dried at 50 ° C for 3 h.

[0043] Step 2: Pour 60 parts by mass of the dimethylformamide solvent into the reaction kettle, warmed to 70 ° C, heat 0.5 parts of sodium chloride in the reaction (stirred at a stirring frequency of 10 Hz for 20 min, stir After the addition of 18 parts by mass of sorbitic, the mixture was continued, stirred for 30 min, and the ca...

Embodiment 2

[0047] The specific preparation process of the hollow fiber ultrafiltration membrane is operated as follows:

[0048] Step 1: Dissolve 20 parts of the mass particle in N-methylpyrrol, form a phase solution, a acetyl chloride having a mass fraction of 25 parts, a mass fraction of 10 parts of aluminum In N-methylpyrrolene, in a slowly pour in a homogeneous solution at 90 ° C, stir, and the reaction was refluxed for 1 h. The product was washed with secondary distilled water, dried under the oven at 90 ° C for 16 h after filtration, to obtain a carboxylated modified polyether sulfone, spare; a mass fraction of a polyary ether sulfone resin was dried at 100 ° C for 5 h.

[0049] Step 2: Pour 70 parts by mass of N-methylpyrrolidone solvent into the reaction kettle, warmed to 90 ° C, heat 2.5 parts of lithium chloride in the reaction ratio of 10 hours at a stirring frequency of 10 Hz 10 min, stir After the addition of 14.5 parts by mass of the polyethylene glycol 400, the mixture was con...

Embodiment 3

[0053] The specific preparation process of the hollow fiber ultrafiltration membrane is operated as follows:

[0054] Step 1: Dissolve the mass fraction of 17 parts of polyether sulfone in N-methylpyrrolene, form a homogeneous solution, and 22 parts of a acetyl chloride, a mass fraction of 8 parts of aluminum In N-methylpyrrolene, in a slowly poured in a homogeneous solution at 85 ° C, stirred, and the reaction was refluxed for 2 h. The product was washed with secondary distilled water, dried under the oven at 100 ° C for 15 h after filtration, and the carboxylated modified polyether sulfone is obtained; the mass fraud is 40 ° C for 4 h. Stick at 80 ° C.

[0055] Step 2: Pour 62 parts by mass of N-methylpyrrolidone solvent into the reaction kettle, warmed to 80 ° C, after heating, 2 parts by mass of lithium chloride added to the reaction kara, stirred at 10 Hz stirring frequency. 10 min, After stirring, 17 parts by mass of the polyethylene glycol 400, and the mixture of Tween 80 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com