Environment-friendly purification device for treating polishing dust residues

A purification device and environmental protection technology, which can be used in combination devices, human health protection, climate change adaptation, etc., can solve the problems of inability to filter and adjust, consume kinetic energy, and reduce purification efficiency, so as to ensure the filtering and purification effect, the improvement effect, and the purification of exhaust gas. Efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

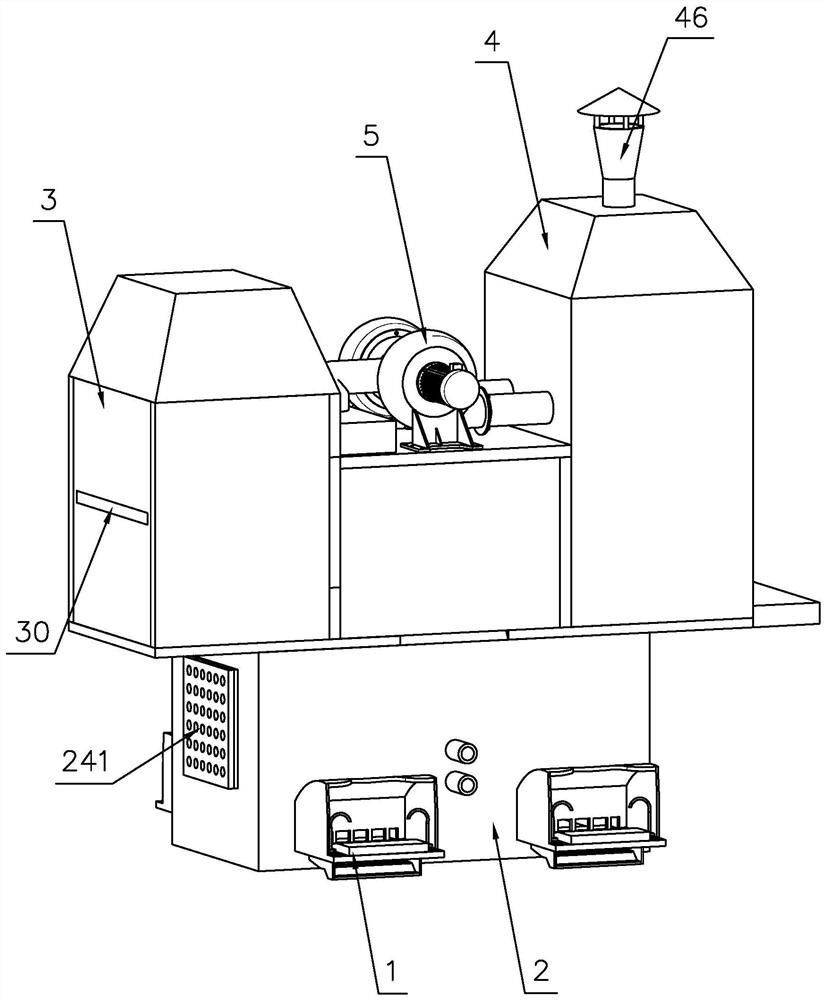

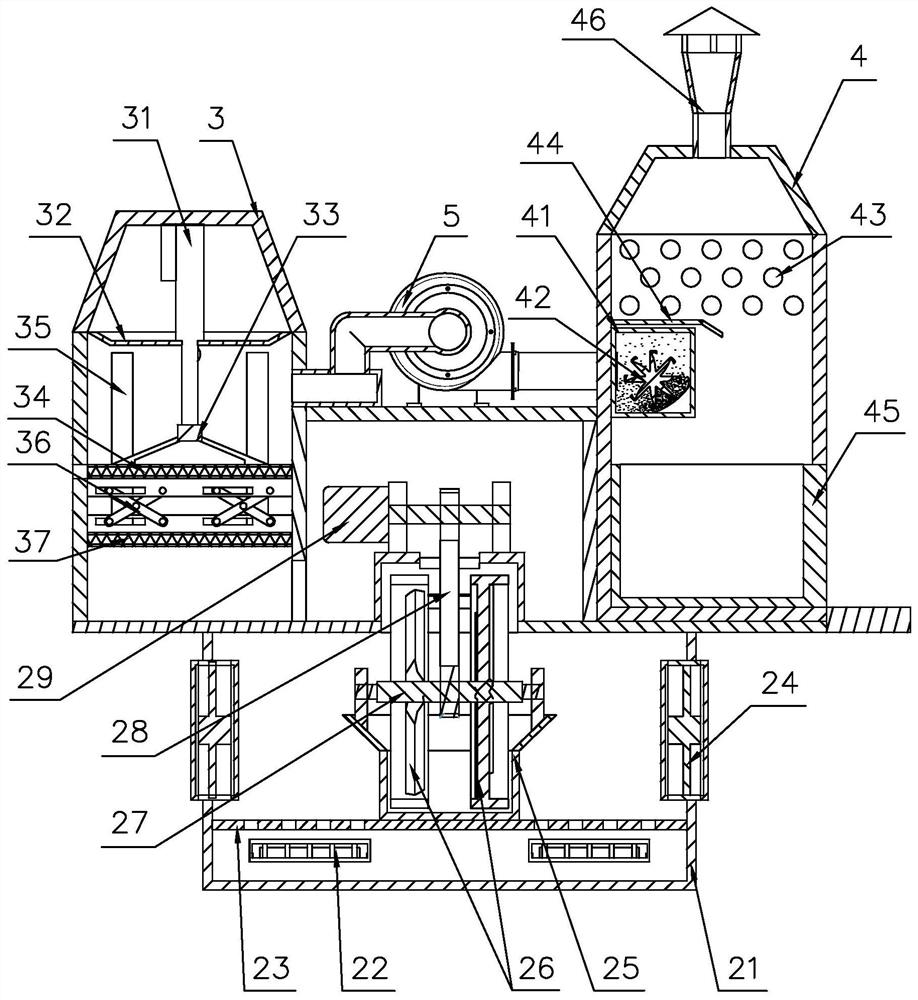

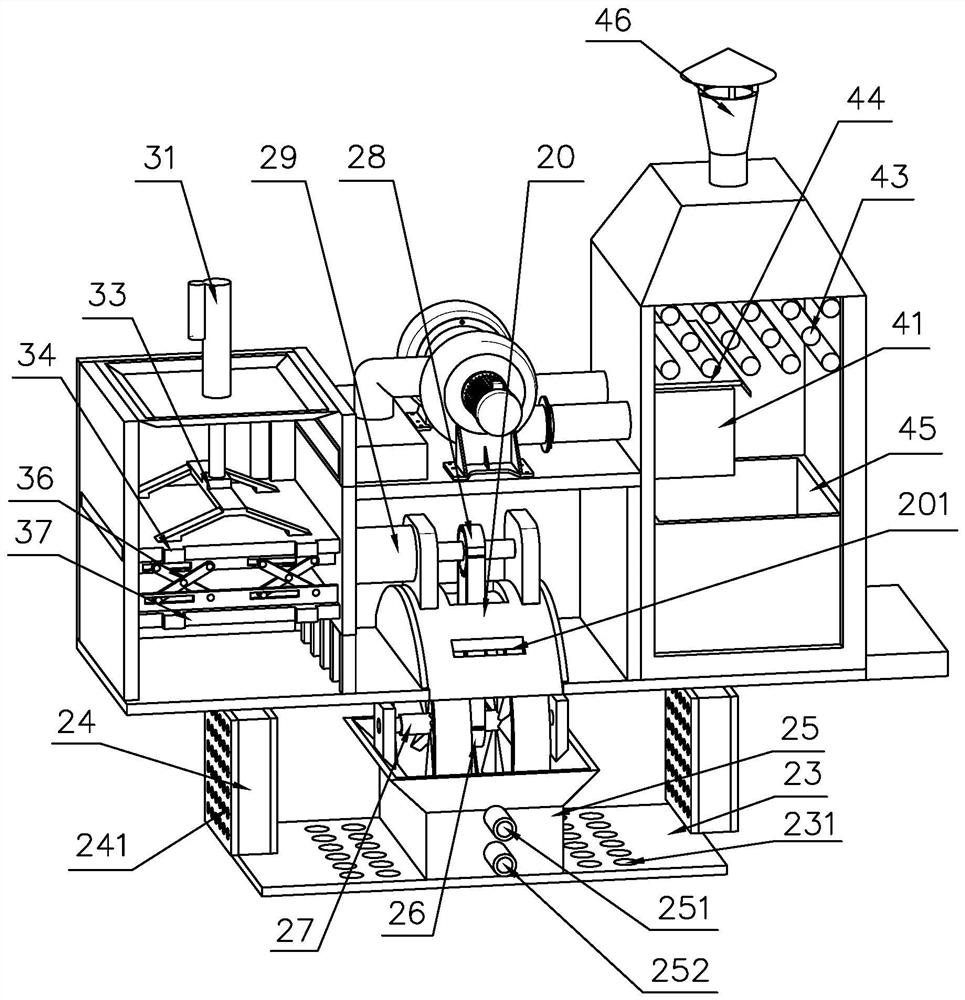

[0026] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-7 , to further specifically describe the technical solution of the present invention.

[0027] An environmental protection purification device for processing grinding dust residues, comprising a grinding workbench 1, a water wheel dust removal mechanism 2, a filter mechanism 3, an adsorption drying mechanism 4, and a fan 5, and a plurality of grinding wheels are arranged on one side of the water wheel dust removal mechanism 2 Workbench 1, filter mechanism 3 is installed on one side of water wheel dedusting mechanism 2, fan 5 is installed on one side of filter mechanism 3, adsorption drying mechanism 4 is installed on the side of fan 5, dynamic power is provided by fan 5, and exhaust gas flows. When dust is generated on the grinding table 1, the dust enters the water wheel dust removal mechanism 2, and the water wheel dust removal mechanism 2 enters the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com