Battery and battery pole piece, manufacturing method and device thereof

A technology of battery pole piece and pole piece, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc. The pole pieces cannot be well bonded, so as to achieve good follow-up cycle performance, good wetting effect, and improve the effect of difficulty in entering the shell or packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

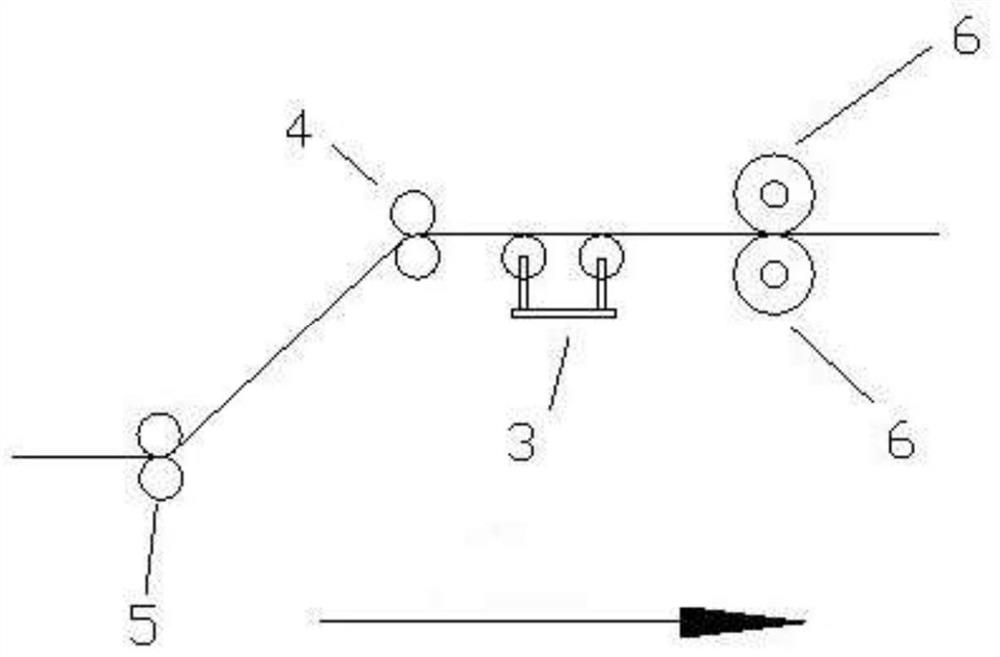

[0062] A method for making battery pole pieces, the steps are the same as those of the comparative example, the difference is that, as image 3 As shown, after the conductive lugs for the battery core are formed by a die-cutting machine, the pole piece 1 passes through the second flower-making device 5 and the first flower-making device 4, and then the pole piece 1 is cut by a slitting machine 6 . During work, only the first flower-making device 4 is operated, the cylinder pressure of the first flower-making device 4 is 0.3MPa, and the first flower-making device 4 handles a tape transport speed of 80m / min. In the figure, the direction of the arrow is the tape running direction of the pole piece 1 .

[0063] Such as Figure 5 As shown, the batteries prepared in the comparison examples and examples are studied in the 1C / 1C charge-discharge cycle performance, and the observation of the experimental data shows that at 25 ° C, the battery is charged and discharged, and the mode of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com