Method of predicting turbine wheel life

A technology of turbine impeller and life, which is applied in the field of micro-combustion turbine turbines, and can solve problems such as limited static strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

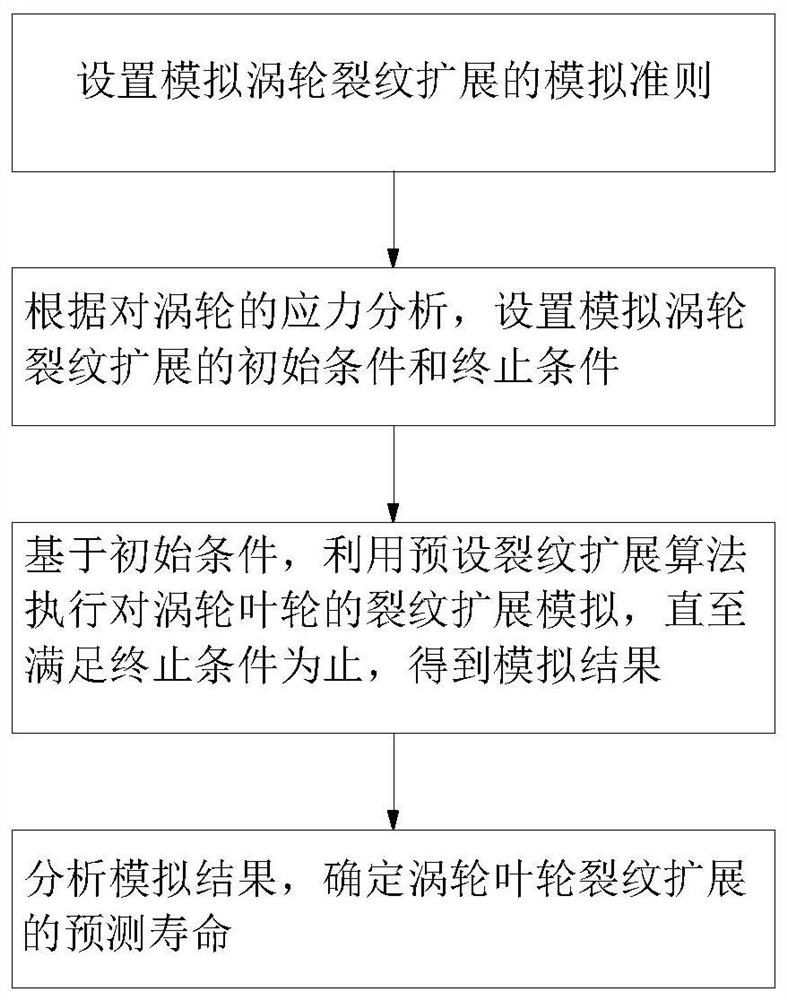

[0048] Embodiment 1 The method for predicting the service life of turbine impeller

[0049] The material of the turbine processed in this embodiment is exemplarily selected as K424 superalloy. K424 alloy is a new cast nickel-based superalloy independently developed by my country. It has high high-temperature strength, good plasticity and manufacturability, and high comprehensive performance. It is suitable for manufacturing turbine rotor blades and guide vanes that work below 950 ° C. part.

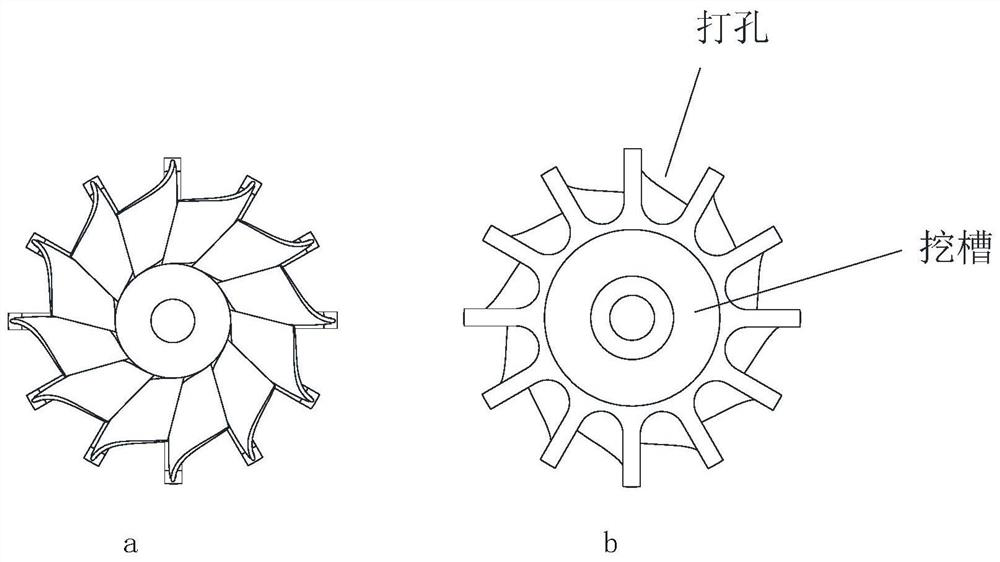

[0050] Such as figure 1 As shown in a and b, the geometric model of the turbine has a total of 12 blades, the radius of the wheel disc is 37mm, and the radius of the central hole matching the shaft is 4.5mm. Grooves and holes are dug on the turbine.

[0051]The specific material parameters of K424 cast superalloy are shown in Table 1.

[0052] Table 1 Material parameters of K424 alloy (600℃)

[0053]

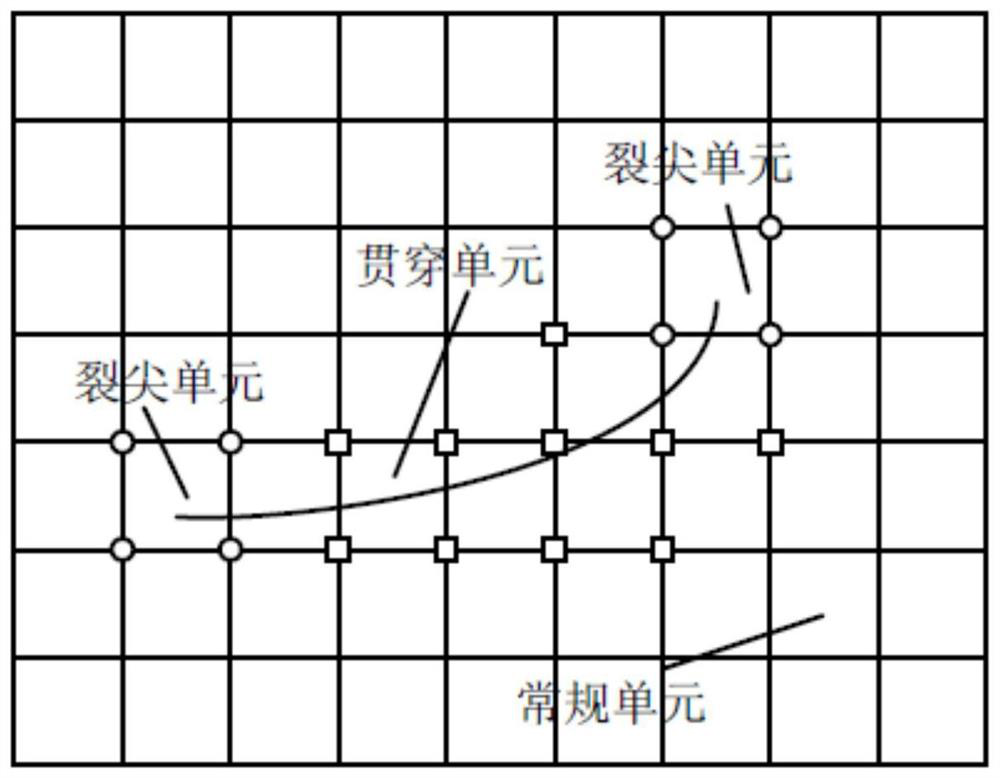

[0054] The scheme for predicting the life of turbine blades is mainly based on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com