Method for detecting thickness of accumulated dust on outer wall of pipeline and detection system

A technology for detecting the thickness of dust deposits and pipes, which is applied to measuring devices, instruments, and the use of ultrasonic/sonic/infrasonic waves, etc. It can solve the problems of cumbersome installation, inaccurate or damaged heat flow meter measurement, and high cost of heat flow meter, etc., and achieve a simple solution , improve the efficiency of operation and management, and realize the effect of quantification and classification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

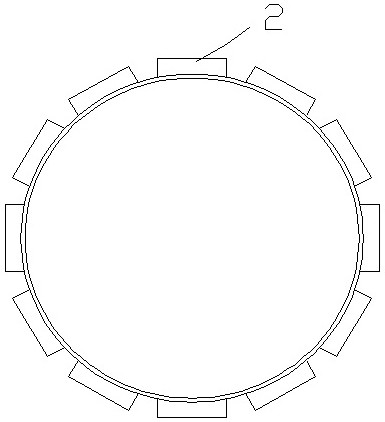

[0021] A detection system for detecting the thickness of dust accumulation on the outer wall of a pipeline, characterized in that: the detection system includes a processing device 1, a plurality of excitation units 2 and a plurality of receiving units 3;

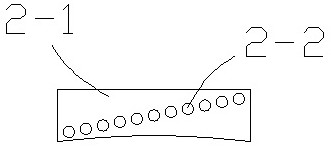

[0022] A single excitation unit 2 includes a connecting base 2-1 and a plurality of ultrasonic exciters; the bottom surface of the connecting base 2-1 is an arc surface matching the surface of the pipeline, the bottom surface of the connecting base 2-1 is embedded with a magnet, and the connecting base 2-1 passes through the magnet Adsorbed on the surface of the pipeline; there are multiple installation cavities in the connection seat 2-1, and multiple ultrasonic exciters are arranged in multiple installation cavities in a one-to-one correspondence; the excitation end 2-2 of the ultrasonic exciter is located in the connection seat 2-1 The end surface of one axial end, and the end surface of the excitation end 2-2 is perpendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com