Cantilever structure elastic foil dynamic pressure air floatation thrust bearing

An elastic foil and thrust bearing technology, applied in the field of foil dynamic pressure gas bearings, can solve the problems of increasing the complexity of the bearing structure, increasing the complexity of the process and the difficulty of assembly, and limiting the large-scale application in the civilian field. Reliability of start-stop, ease of frictional heat generation, inability to effectively cool down, and beneficial effect of air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings. The positional relationships such as left and right, up and down, etc. mentioned in the text are only a description of the relative relationship of the parts shown in the pictures given in the accompanying drawings, which is convenient for introduction and reference, and does not represent actual use. Time.

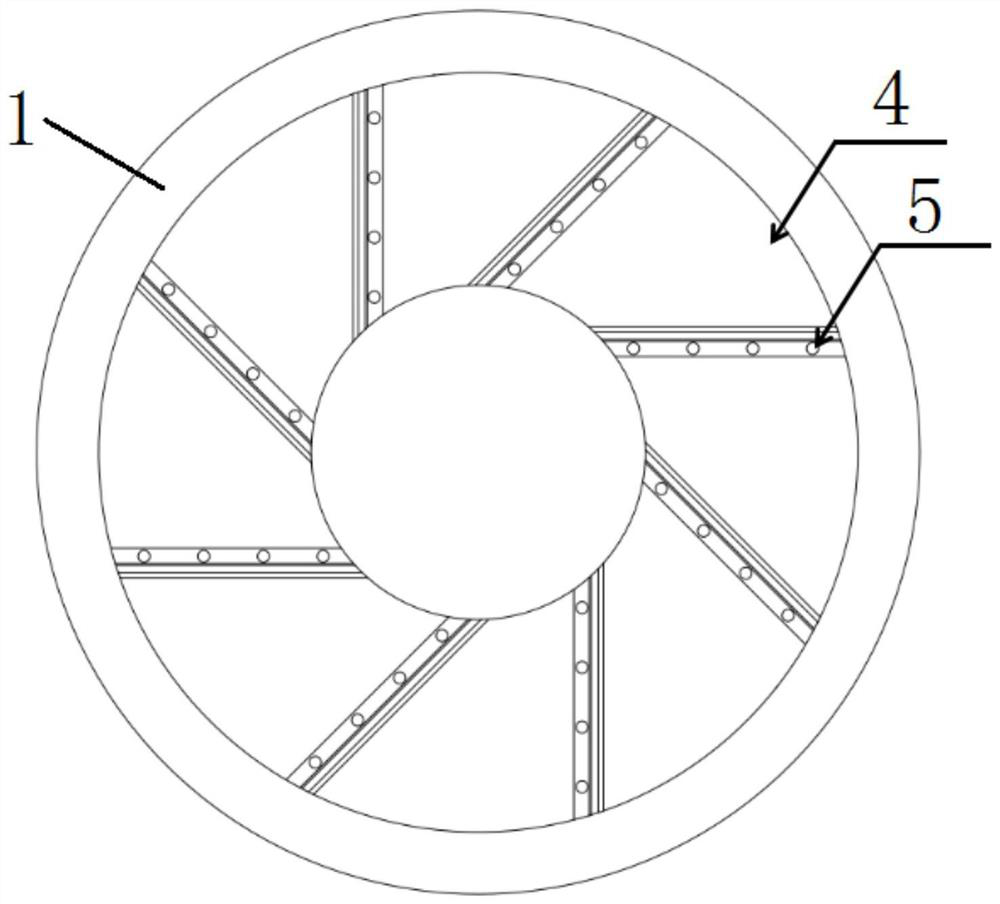

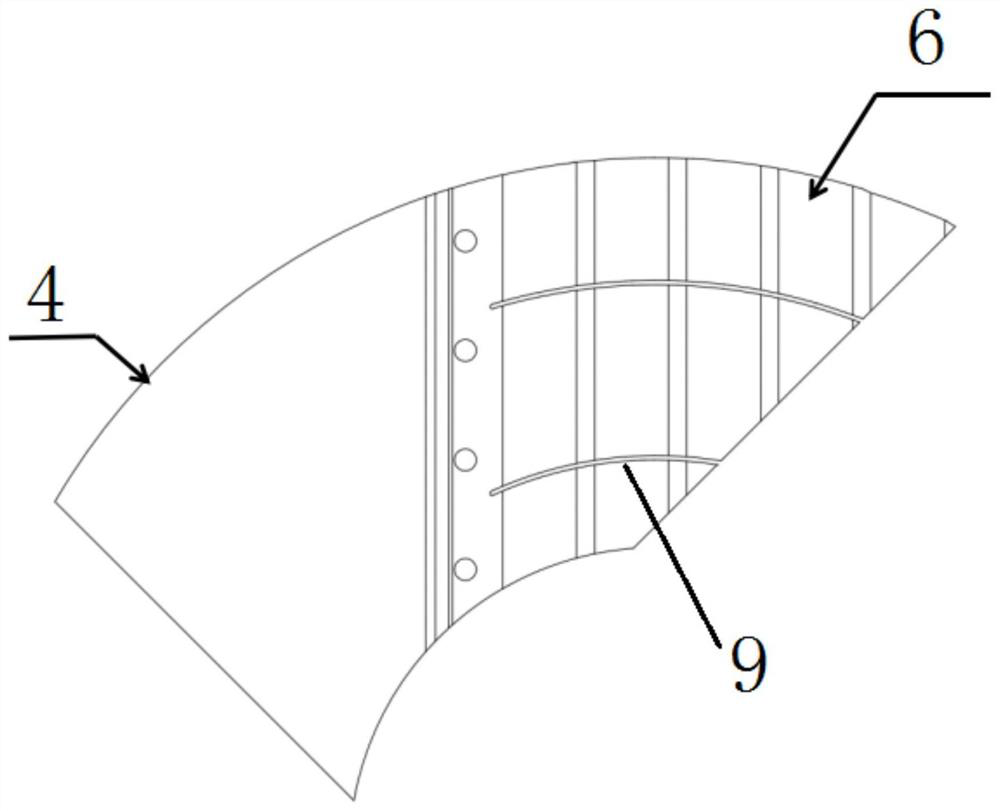

[0030] Such as Image 6As shown, the present invention provides a cantilever structure elastic foil dynamic pressure air bearing, which includes a thrust bearing housing 1 , several cantilever structure elastic foils 2 and a thrust plate 3 . The thrust bearing seat 1 is used to provide a rigid support structure for the cantilever elastic foil 2 and the thrust plate 3 . The elastic foil 2 of the cantilever structure is used for the thrust plate to provide an elastic bearing unit and a solid lubricating surface, to maintain the stability of the dynamic pressure air f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com