Energy-saving control system based on roots vacuum pump

An energy-saving control system, Roots vacuum pump technology, applied to components, pumps, pump components, etc. of pumping devices for elastic fluids, can solve the problems of increased energy consumption, inability to dissipate heat, and increased energy consumption of vacuum pumps, etc., to achieve Improve the cooling and heat dissipation speed, improve work efficiency, and avoid the effect of overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

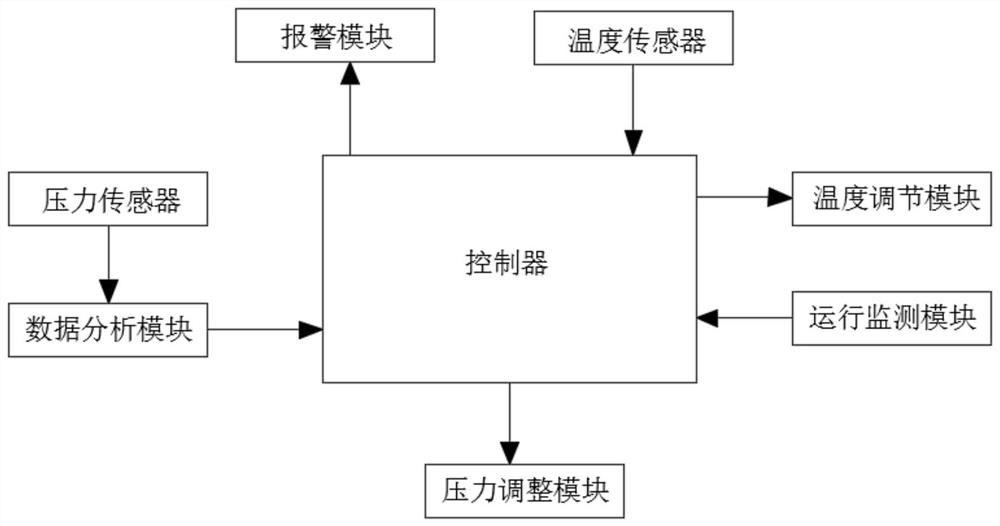

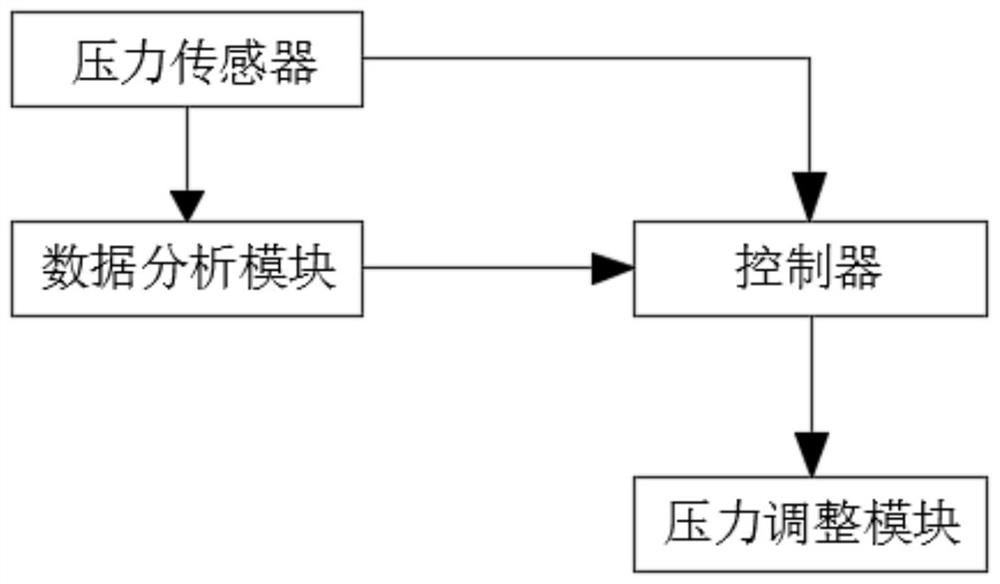

[0053] Such as figure 2 As shown, the pressure sensor: installed at the exhaust port of the vacuum pump, used to collect the pressure at the exhaust port of the vacuum pump in real time and send it to the data analysis module;

[0054] Data analysis module: used to obtain the pressure at the exhaust port of the vacuum pump and compare the pressure with the set value. If the pressure at the exhaust port of the vacuum pump is greater than the set value, a pressure adjustment signal is generated;

[0055] The data analysis module is used to transmit the pressure adjustment signal to the controller, and the controller drives and controls the pressure adjustment module to adjust the pressure after receiving the pressure adjustment signal;

[0056] The pressure adjustment module is used to control the opening of the corresponding overflow solenoid valve according to the pressure difference between the current pressure and the set value, and adjust the ratio of the power of the vacu...

Embodiment 2

[0059] Such as image 3 As shown, the temperature sensor: set on the inner wall of the pump housing and the outer wall of the pump housing of the vacuum pump, used to collect the temperature of the inner wall of the vacuum pump pump housing and the outer wall of the pump housing in real time, and pass the collected temperature of the inner wall of the vacuum pump pump housing and the outer wall of the pump housing to the controller transmitted to the temperature regulation module;

[0060] The temperature adjustment module is a condenser, which is used to control the temperature of the cooling water flowing through the vacuum pump through the condenser according to the current temperature of the inner wall of the vacuum pump casing and the outer wall of the pump casing, so as to dissipate heat from the vacuum pump; the specific control method is as follows:

[0061] Step 1: Obtain the current temperature of the inner wall of the pump casing and the outer wall of the pump casin...

Embodiment 3

[0069] Such as Figure 4 As shown, the operation monitoring module is used to collect and analyze the operation data of the vacuum pump to judge whether the vacuum pump is running normally. The specific analysis and monitoring process is as follows:

[0070] S1: Collect the operation data of the vacuum pump, mark the noise decibel value of the vacuum pump during operation as Z1, mark the energy consumption per unit time of the vacuum pump as Z2, and mark the difference between the inner wall temperature of the vacuum pump casing and the ambient temperature as Z3;

[0071] S2: Use the formula GX=Z1×a1+Z2×a2+Z3×a3 to calculate the operation detection coefficient GX of the vacuum pump, where a1, a2 and a3 are coefficient factors;

[0072] S3: Comparing the running detection coefficient GX with the detection coefficient threshold;

[0073] If the operation detection coefficient GX≥the detection coefficient threshold, it means that the vacuum pump is in a suspected dangerous stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com