Process method and device for producing composite inorganic fireproof core material for door frame

A fireproof core material and production process technology, which is applied in the direction of selling raw material supply devices, window/door frames, cement mixing devices, etc. The effect of improving the degree of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

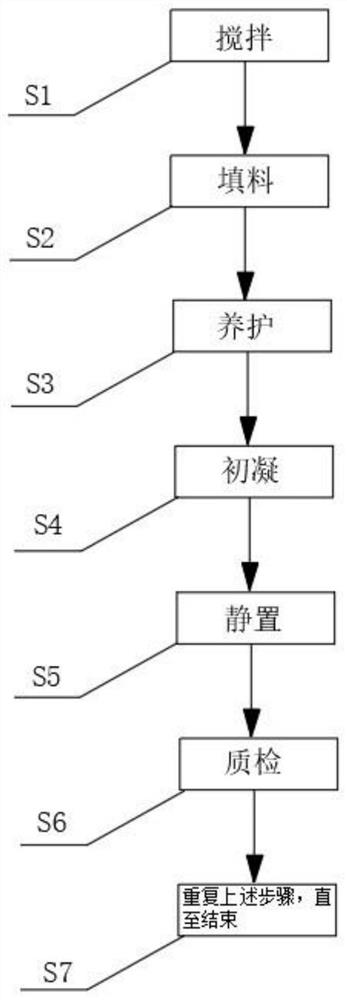

[0028] The production process of the composite inorganic fireproof core material for the door frame specifically includes the following steps:

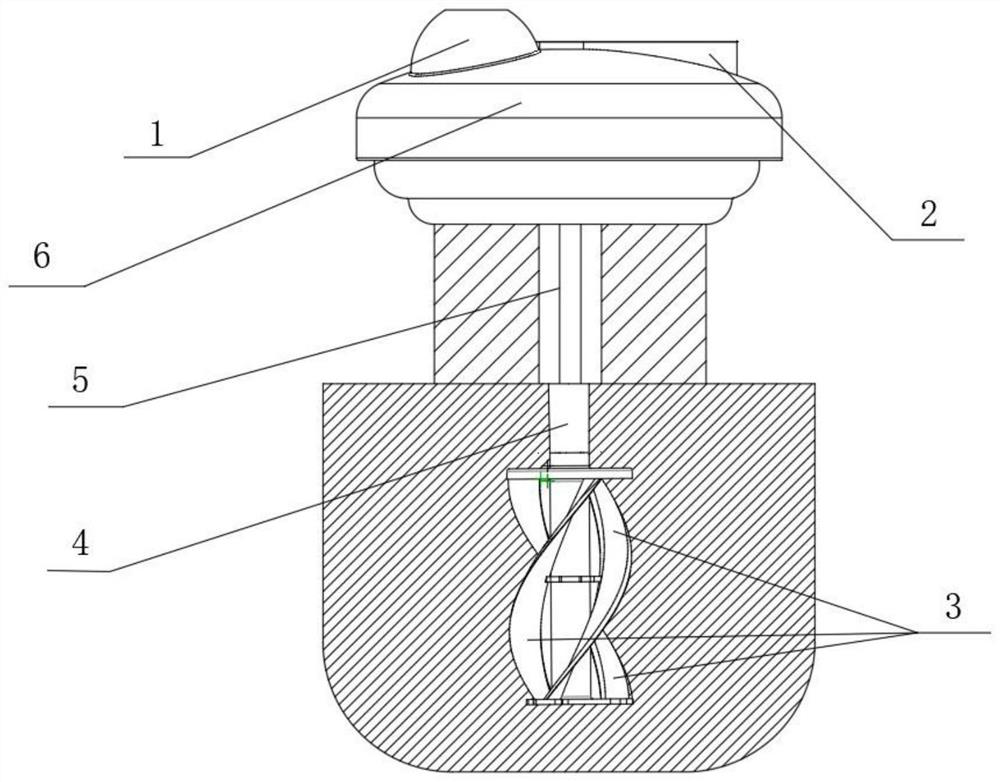

[0029] S1. Stir, add gypsum, cement, powdered coal silicon, compatibilizing particles and polyester fiber into the mixer and stir evenly, the stirring time is 4 minutes;

[0030] S2. Filling, use the filling tool to horizontally fill the stirred filling into the groove of the door frame;

[0031] S3. Maintenance, use a scraper to scrape off the overflowing filler in the frame and the height of the scraped filler is lower than the plane where the side of the door frame is located;

[0032] S4. Initial setting, place the door frame filled with filler for initial setting, and the setting time is 40 minutes;

[0033] S5. Stand still, place the door frame that has reached the solidification time, wherein the standing time is 24h;

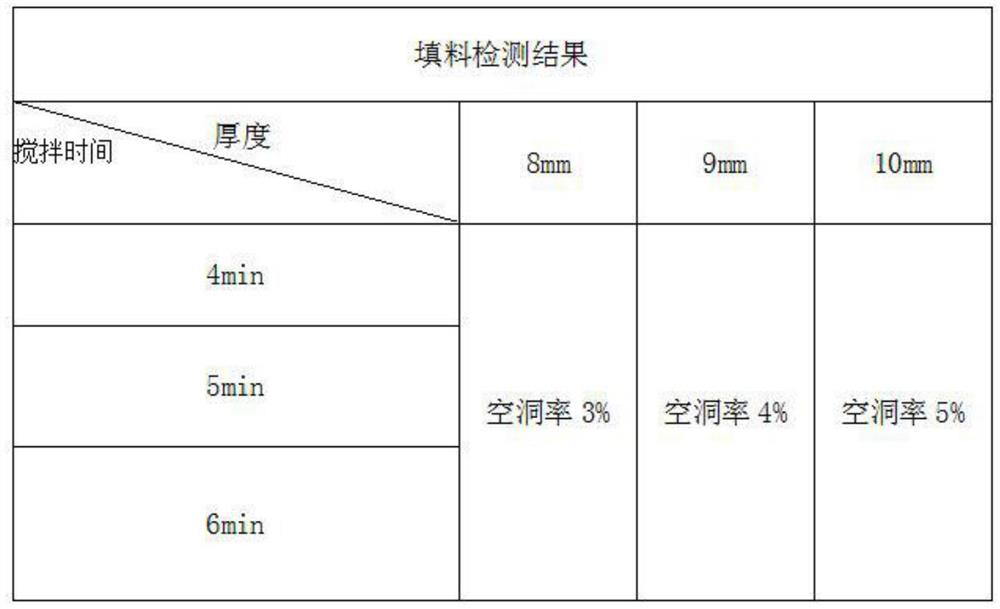

[0034] S6. Quality inspection, random sampling of 100*100 samples in the door frame filled with fillers and...

Embodiment 2

[0038] The production process of the composite inorganic fireproof core material for the door frame specifically includes the following steps:

[0039] S1. Stir, add gypsum, cement, powdered coal silicon, compatibilizing particles and polyester fiber into the mixer and stir evenly, the stirring time is 5 minutes;

[0040] S2. Filling, use the filling tool to horizontally fill the stirred filling into the groove of the door frame;

[0041] S3. Maintenance, use a scraper to scrape off the overflowing filler in the frame and the height of the scraped filler is lower than the plane where the side of the door frame is located;

[0042] S4. Initial setting, place the door frame filled with filler for initial setting, and the setting time is 50 minutes;

[0043] S5. Stand still, place the door frame that has reached the solidification time, wherein the standing time is 24h;

[0044] S6. Quality inspection, random sampling of 100*100 samples in the door frame filled with fillers and...

Embodiment 3

[0048] The production process of the composite inorganic fireproof core material for the door frame specifically includes the following steps:

[0049] S1. Stirring, add gypsum, cement, powdered coal silicon, compatibilizing particles and polyester fiber into the mixer for uniform mixing, and the mixing time is 6 minutes;

[0050] S2. Filling, use the filling tool to horizontally fill the stirred filling into the groove of the door frame;

[0051] S3. Maintenance, use a scraper to scrape off the overflowing filler in the frame and the height of the scraped filler is lower than the plane where the side of the door frame is located;

[0052] S4. Initial setting, place the door frame filled with filler for initial setting, and the setting time is 60 minutes;

[0053] S5. Stand still, place the door frame that has reached the solidification time, wherein the standing time is 48h;

[0054] S6. Quality inspection, random sampling of 100*100 samples in the door frame filled with fill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com