Solid-liquid cooperative soil conditioner for saline-alkali soil and use method thereof

A soil conditioner and technology for saline-alkali soil, applied in the field of solid-liquid cooperative soil conditioner, can solve problems affecting agricultural production, etc., and achieve the effects of ensuring normal growth, improving soil physical and chemical environment, and optimizing physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A solid-liquid cooperative soil modifier for saline base, including a solid phase portion and a liquid phase portion, the solid phase portion comprises carbon manuretria, humic acid and acidic residue, and the weight of the material in the solid phase portion is carbon manure, respectively. 45 parts of the decodes, 27 parts of humic acid, 18 parts of the acidic residue, the solid phase portion mixture is recorded as a modified agent A, and the liquid phase portion includes a wooden vinegar liquid, and the liquid phase is partially described as a modified agent B.

[0025] Among them, carbon manure is a mature-free range of biotic charcoal and fresh pig manure or beef and sheep feces, which is a month, and take the final decomposed product.

[0026] Further, the needle of the humic acid material is mainly treated with ammonium bicarbonate.

[0027] Further, acidic residue is one or more of vinegar, alcohol and furfural slag.

[0028] Among them, the liquid phase portion of t...

Embodiment 2

[0036] The difference from the first example is:

[0037] The solid phase portion includes a carbon maniferus, humic acid and acidic residue, and the weight of the material in the solid phase portion is 48 parts of carbon manure curvature, 28.8 parts of humic acid, 19.2 parts of acidic residue.

[0038] Among them, carbon manure is a matcharrhid and fresh pig manure or beelawheel in a ratio of carbon manure than 1: 8, a month, and taking the final decomposed product.

[0039] Among them, the xylitone fluid in the liquid phase is required to be filtered, then simply distilled, then dilute 80 times to obtain a modified agent B.

[0040] A method of using solid-liquid cooperative soil modifiers for saline bases, including the steps of:

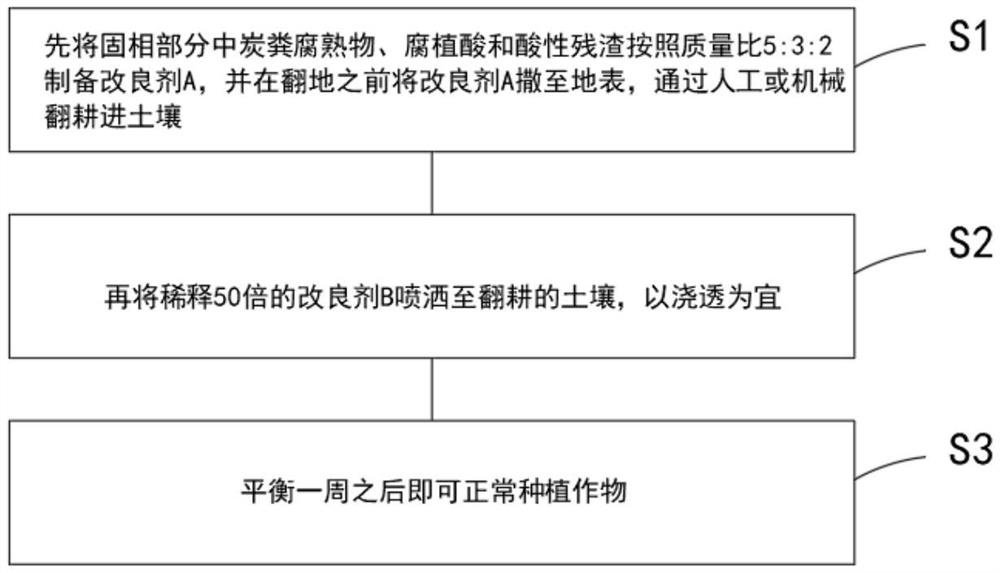

[0041] S1, first preparation of the solid phase part in the solid phase portion, the humic acid and acidic residue prepare the improved agent A in mass than 5: 3: 2, and the modified agent A is sprinkled to the surface before the ground, and the plow...

Embodiment 3

[0045] The difference from the first example is:

[0046] The solid phase portion includes a carbon manuretria, a humic acid and an acidic residue, and the weight of the raw material in the solid phase portion is 50 parts of carbon manure, 30 parts of humic acid, and 20 parts of acidic residue.

[0047] Among them, carbon manure is a mature property of bio-carbon and fresh pig manure or beelary and sheep and sheep feces, which is a month, and take the final decomposed product.

[0048] Among them, the xylitone fluid of the liquid phase is simply distilled after filtration, and then dilutes 100 times to obtain a modified agent B.

[0049] A method of using solid-liquid cooperative soil modifiers for saline bases, including the steps of:

[0050] S1, first preparation of the solid phase part in the solid phase portion, the humic acid and acidic residue prepare the improved agent A in mass than 5: 3: 2, and the modified agent A is sprinkled to the surface before the ground, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com