Tray conveying system suitable for real-time detection of the whole circumference of fruit

A real-time detection and pallet conveying technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve problems affecting internal and external quality detection and grading effects, achieve fast and simple image processing methods, reduce the number of layouts, Effect of reducing testing equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

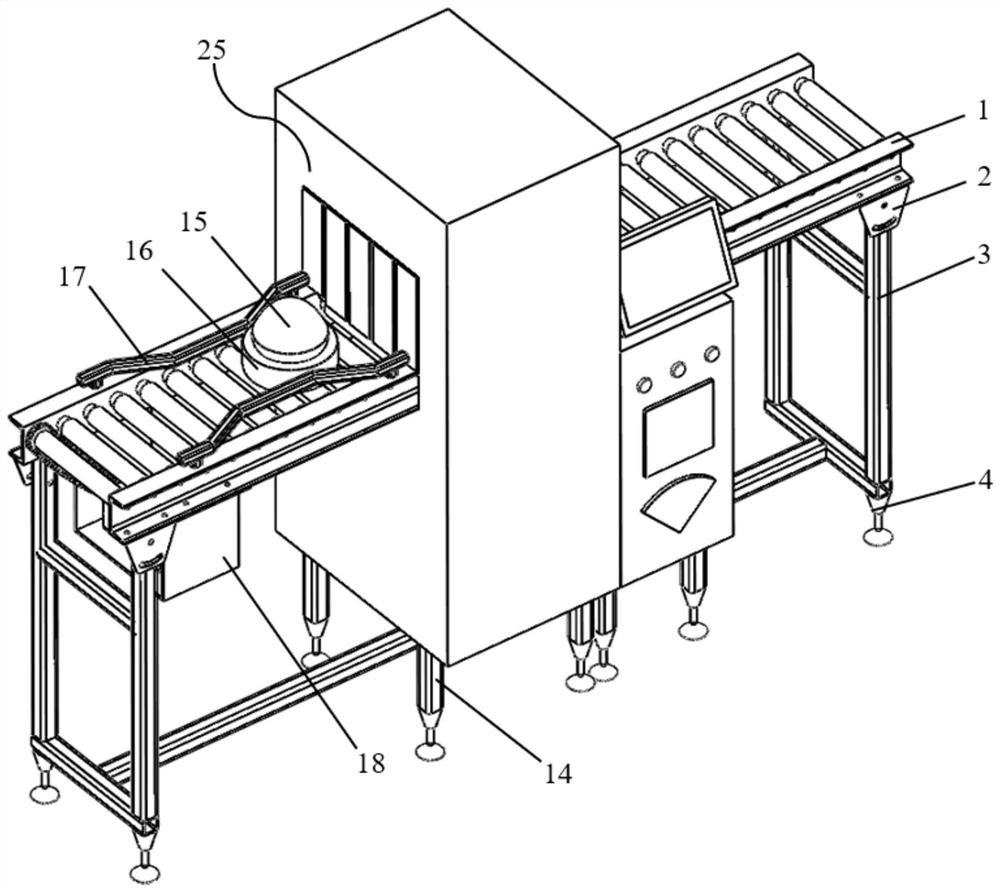

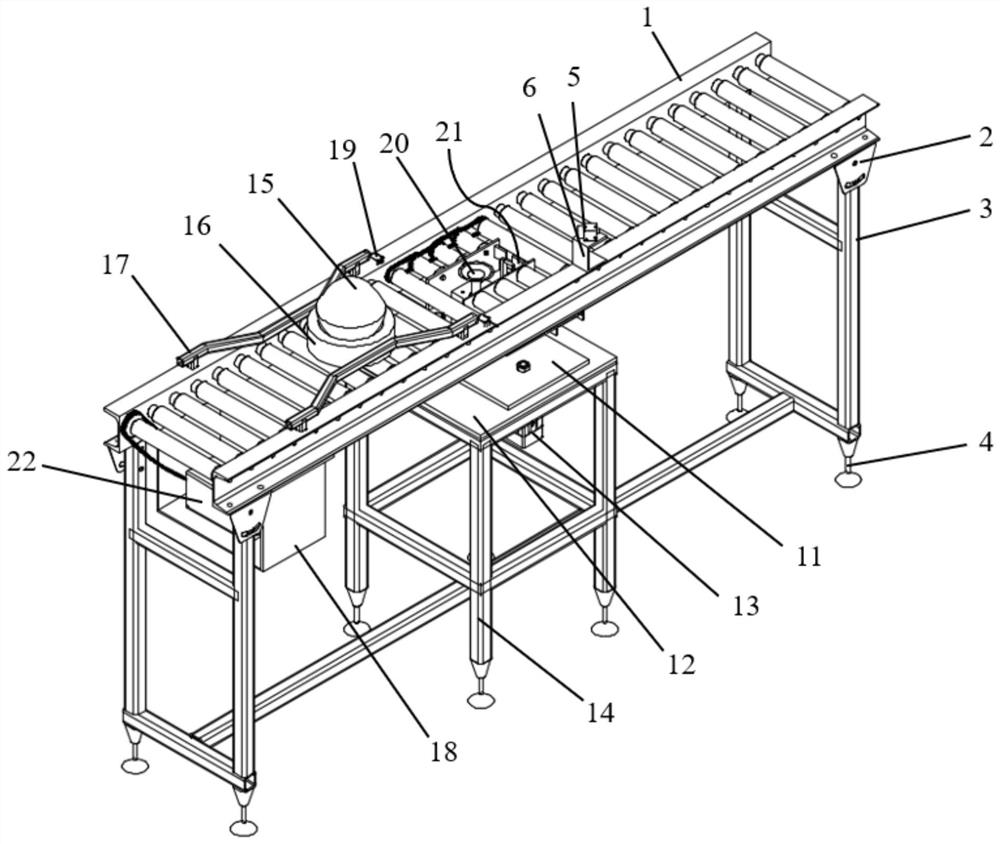

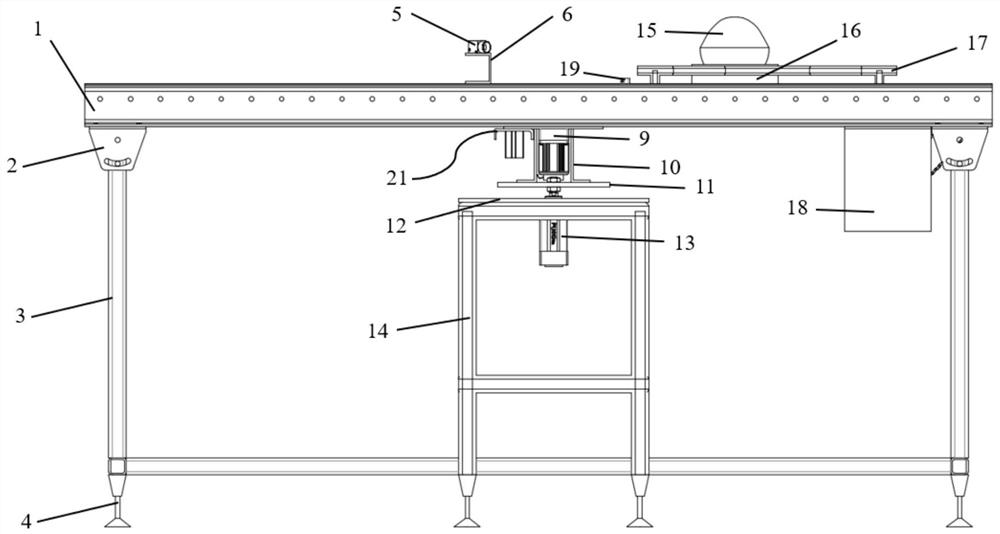

[0035] Taking the internal and external quality detection of pomelo as an example, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0036] Such as Figure 1-Figure 4 As shown, the present invention includes three parts: a transmission system, a jacking and rotating mechanism, and a detection device. The jacking and rotating mechanism is located below the transmission system, and the detection equipment is installed on the jacking and rotating mechanism; 3. Fruit 15, fruit cup 16, diversion guardrail 17, photoelectric sensor 19, brake device 21, first motor 22 and sprocket chain 24; the roller conveyor belt 1 is fixedly installed on the conveyor belt bracket 3 through the corner code 2 , transfer fruit cup 16 on the roller conveyor belt 1, place fruit 15 on the fruit cup 16; The shaft is connected with the sprocket chain 24, and the roller 1c is driven by the sprocket chain 24 to drive the roller conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com