Upgrading method for paper-making reconstituted tobacco water paste, tobacco water paste and application

A technology of reconstituted tobacco leaves and papermaking, which is applied in the fields of tobacco, application, and treatment of tobacco, can solve the problems of reducing the coating effect of reconstituted tobacco leaves, increasing the frequency of replacing filter screens, and limited efficiency of centrifuges, etc., to achieve extended storage time, The effect of short time consumption and reduction of energy consumption cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

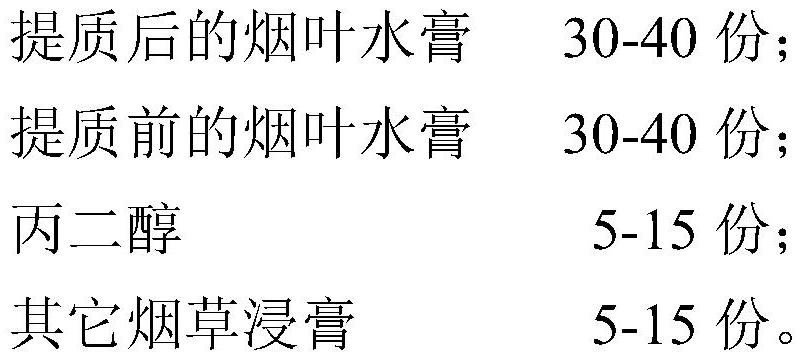

Method used

Image

Examples

Embodiment 1

[0040] This embodiment discloses a method for improving the quality of reconstituted tobacco leaf paste by papermaking method, and the specific steps are as follows:

[0041] (1) Extraction: mix 0.4m of tobacco stem, 0.4m of tobacco dust and 0.2m of fragments with 6m of water, and extract for 2 hours at 60°C; separate solid and liquid to obtain an extract; The extraction liquid was centrifuged for 10 min with a decanter centrifuge at a rotational speed of 5000 rpm to obtain a tobacco extract. where m is greater than 0.

[0042] (2) Primary concentration: the tobacco extract is concentrated under reduced pressure at 60°C and a vacuum of 0.07Mpa to a solid content of 40%wt to obtain the primary tobacco water paste.

[0043] (3) Quality improvement: take cornstarch and diatomaceous earth, and mix them evenly in a mass ratio of 6:4 to obtain an edible grade quality improvement agent; in the initial product of tobacco water paste with a quality of n, add a quality of 0.2n edible ...

Embodiment 2

[0047] This embodiment discloses a method for improving the quality of reconstituted tobacco leaf paste by papermaking method, and the specific steps are as follows:

[0048](1) Extraction: Mix 0.3m of tobacco stems, 0.4m of tobacco dust and 0.3m of fragments with 7m of water, and extract at 65°C for 1.5h; separate solid-liquid to obtain an extract; The extract was centrifuged for 5 min with a decanter centrifuge at 5500 rpm to obtain a tobacco extract. where m is greater than 0.

[0049] (2) One-time concentration: the tobacco extract is concentrated under reduced pressure to a solid content of 45%wt under the condition of 65°C and a vacuum degree of 0.07Mpa to obtain the first product of tobacco water paste.

[0050] (3) Quality improvement: take corn starch and diatomaceous earth, and mix them evenly in a mass ratio of 9:1 to obtain a food-grade quality-enhancing agent; in the first product of tobacco water paste with a quality of n, add edible quality of 0.3n Grade impro...

Embodiment 3

[0054] The present embodiment discloses a method for improving the quality of the reconstituted tobacco leaf water paste by the papermaking method, and the specific steps are as follows:

[0055] (1) Extraction: Mix 0.4m of tobacco stems, 0.3m of tobacco powder and 0.3m of fragments with 8m of water, and extract at 60°C for 1.5h; separate the solid and liquid to obtain the extract; The extract was centrifuged for 10 min with a butterfly centrifuge at 6000 rpm to obtain a tobacco extract. where m is greater than 0.

[0056] (2) One-time concentration: under the condition of 65 DEG C and vacuum degree of 0.07Mpa, the tobacco extract is concentrated under reduced pressure to a solid content of 40%wt to obtain the first product of tobacco water paste.

[0057] (3) Quality improvement: take corn starch and diatomaceous earth, and mix them evenly at a mass ratio of 8:2 to obtain a food-grade quality-enhancing agent; in the first product of tobacco water paste with a quality of n, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com