Electrolyte and lithium ion battery

A technology of electrolyte and lithium salt, applied in the field of electrolyte and lithium ion battery, can solve the problems of low impedance and low gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

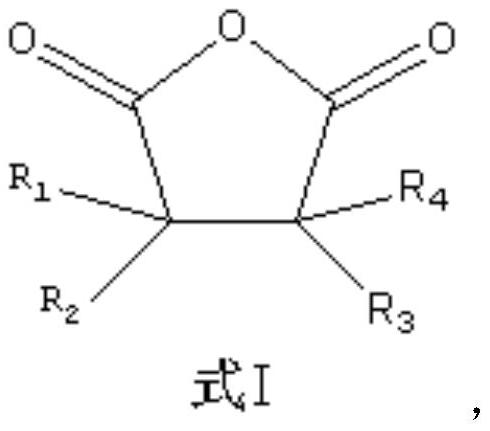

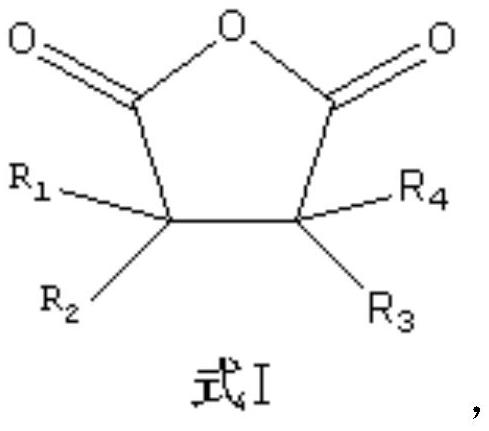

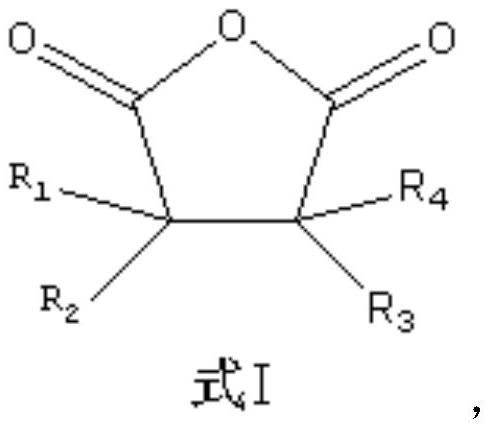

Method used

Image

Examples

Embodiment 1

[0045] 1) Preparation of lithium-ion battery cathode sheet: the cathode active material LiNi 0.88 co 0.09 mn 0.03 o 2 , conductive carbon, binder polyvinylidene fluoride (PVDF) and N-methylpyrrolidone (NMP) are uniformly mixed to prepare positive electrode slurry. The solid content of the positive electrode slurry is 72wt%, wherein, LiNi 0.88 co 0.09 mn 0.03 o 2 : The mass ratio of conductive carbon: PVDF is 97:2:1. The positive electrode slurry was coated on the aluminum foil of the current collector, dried at 80°C and then cold pressed, and then cut into pieces, and placed in a vacuum oven at 85°C for 12 hours to make a lithium ion battery positive sheet.

[0046] 2) Preparation of lithium-ion battery negative electrode sheet: Negative electrode active material artificial graphite, conductive carbon, thickener carboxymethyl cellulose (CMC), binder styrene-butadiene rubber (SBR) are mixed uniformly in deionized water to make a negative electrode slurry. The solid con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com