Method for testing temperature of clutch friction plate in complete machine state of transmission

A test method and clutch technology, applied in the transmission field, can solve the problems of limited applicable conditions, high cost of temperature sensors, poor versatility, etc., and achieve the effects of low cost and avoiding clutch burnout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] test a clutch

[0052] S1: In the state of parts, the transmission case near the A clutch is drilled to form an outer hole; the outer hub of the A clutch is drilled to form an oil hole.

[0053] S2: After the transmission is assembled, fix the temperature sensor on the transmission housing with screws to ensure that the temperature sensor can be aligned with the oil hole on the outer hub of the clutch after passing through the outer hole.

[0054] S3: Install the transmission on the transmission loading test bench.

[0055]S4: Start the experiment; control the outer hub of clutch A to fix, test the temperature difference of the clutch friction plate under different slip and torque, and record the data, as shown in Table 1.

[0056] Table 1

[0057]

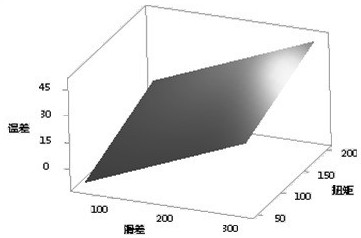

[0058] S5: According to the test data in Table 1, use processing software such as EXCEL or MINTAB to fit the relationship between the clutch temperature difference and slip and torque, such as figure 1 Shown; At the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com