A high-efficiency continuous medicine drying device

A technology for drying devices and medicines, which is used in dryers for stationary materials, drying of solid materials, and handling of dry goods, etc., can solve the problems of low dehydration efficiency, high risk, poor dehydration effect, etc., to improve dehydration efficiency and effective adsorption. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

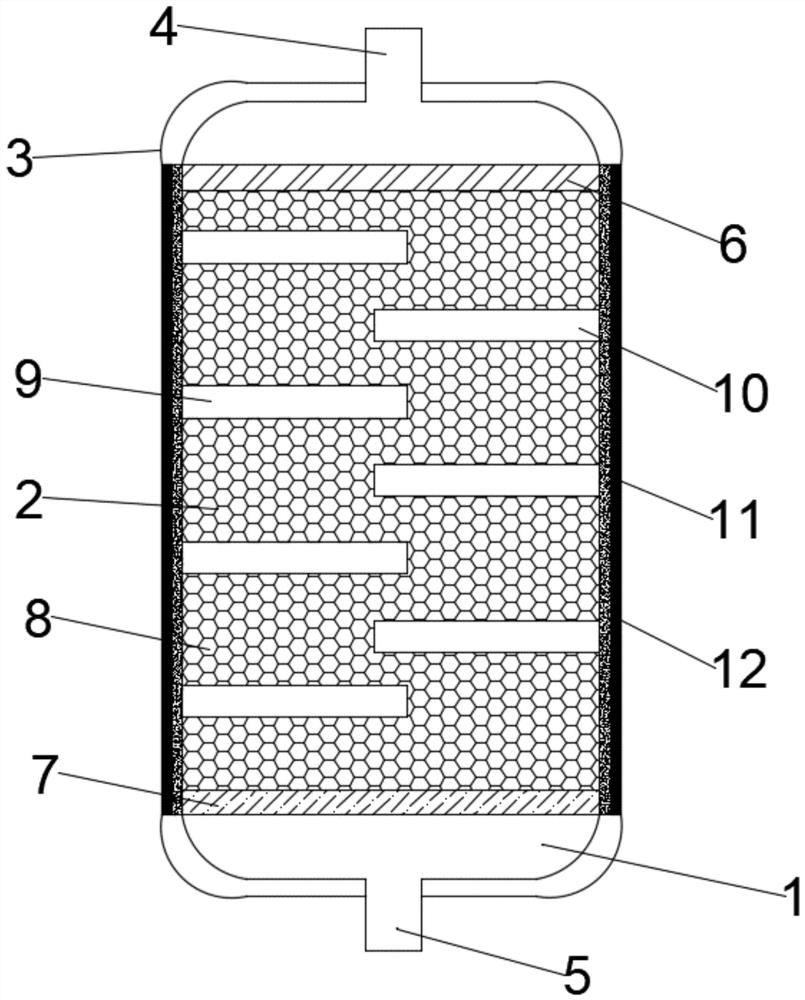

[0032] An efficient and continuous medicine drying device, such as figure 1 As shown, it includes a drying device body 1. The drying device body 1 includes a device cavity 2 and a device housing 3 arranged on the surface of the device cavity 2. The upper port of the device cavity 2 is provided with a discharge port 4. The device cavity A feed port 5 is provided at the lower port of 7. Desiccant 8 is filled between the air guide plate 6 and the diffuser plate 7 .

[0033] Several groups of first baffles 9 and second baffles 10 are arranged between the guide plate 6 and the diffuser plate 7 , the first baffle 9 is arranged on the left side of the inner wall of the device cavity 2 , and the second baffle 10 is arranged at the On the right side of the inner wall of the device cavity 2 , the first baffles 9 and the second baffles 10 are staggered at equal intervals.

[0034] A heating layer 11 and an insulating layer 12 are disposed between the device cavity 2 and the device casi...

Embodiment 2

[0046] An efficient and continuous medicine drying device, such as figure 1 As shown, it includes a drying device body 1. The drying device body 1 includes a device cavity 2 and a device housing 3 arranged on the surface of the device cavity 2. The upper port of the device cavity 2 is provided with a discharge port 4. The device cavity A feed port 5 is provided at the lower port of 7. Desiccant 8 is filled between the air guide plate 6 and the diffuser plate 7 .

[0047] Several groups of first baffles 9 and second baffles 10 are arranged between the guide plate 6 and the diffuser plate 7 , the first baffle 9 is arranged on the left side of the inner wall of the device cavity 2 , and the second baffle 10 is arranged at the On the right side of the inner wall of the device cavity 2 , the first baffles 9 and the second baffles 10 are staggered at equal intervals.

[0048] A heating layer 11 and an insulating layer 12 are disposed between the device cavity 2 and the device casi...

Embodiment 3

[0059] An efficient and continuous medicine drying device, such as figure 1 As shown, it includes a drying device body 1. The drying device body 1 includes a device cavity 2 and a device housing 3 arranged on the surface of the device cavity 2. The upper port of the device cavity 2 is provided with a discharge port 4. The device cavity A feed port 5 is provided at the lower port of 7. Desiccant 8 is filled between the air guide plate 6 and the diffuser plate 7 .

[0060] Several groups of first baffles 9 and second baffles 10 are arranged between the guide plate 6 and the diffuser plate 7 , the first baffle 9 is arranged on the left side of the inner wall of the device cavity 2 , and the second baffle 10 is arranged at the On the right side of the inner wall of the device cavity 2 , the first baffles 9 and the second baffles 10 are staggered at equal intervals.

[0061] A heating layer 11 and an insulating layer 12 are disposed between the device cavity 2 and the device casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com