Apparatus method for wet treatment of wafers

A technology for wet processing and equipment, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

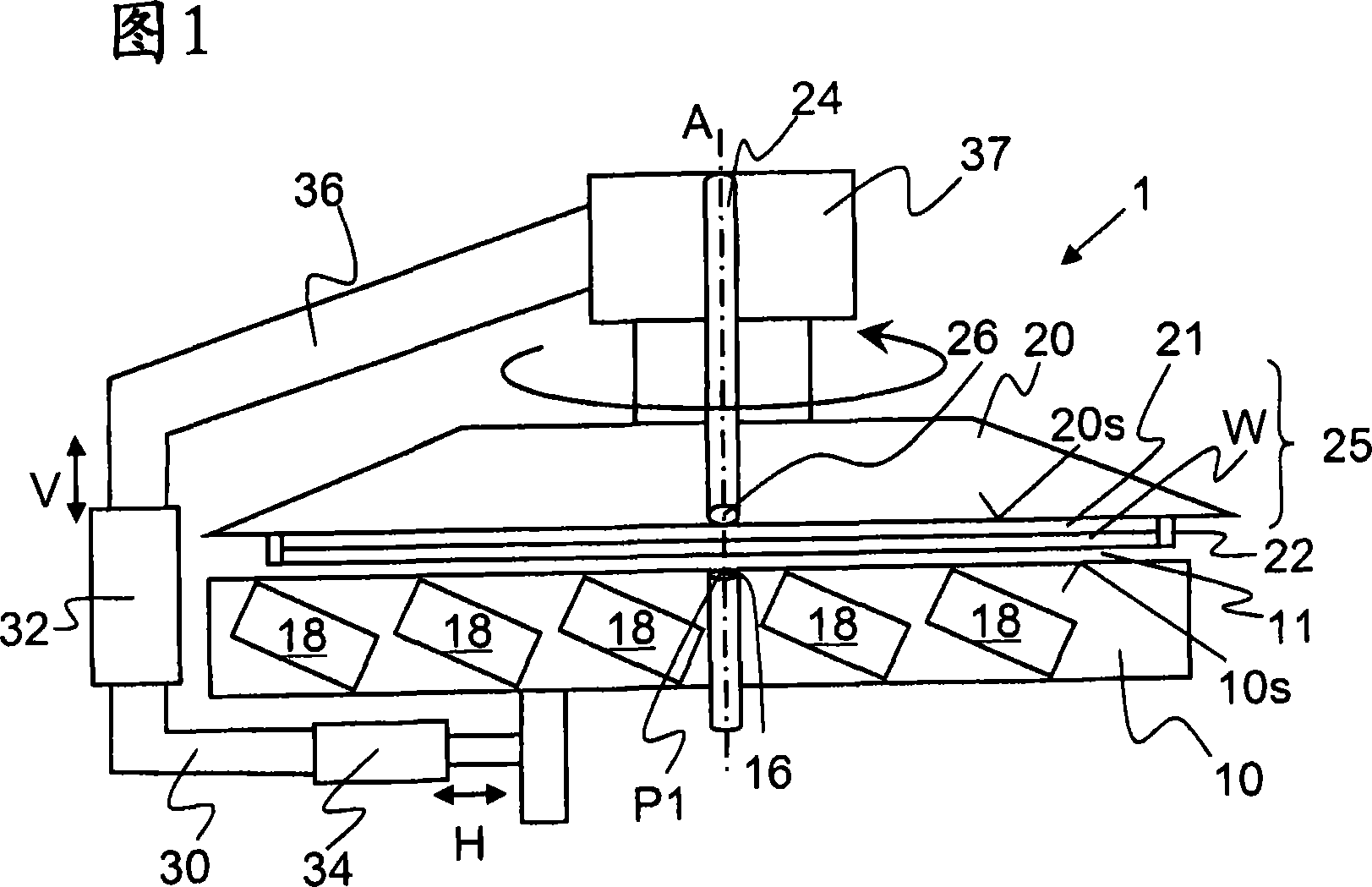

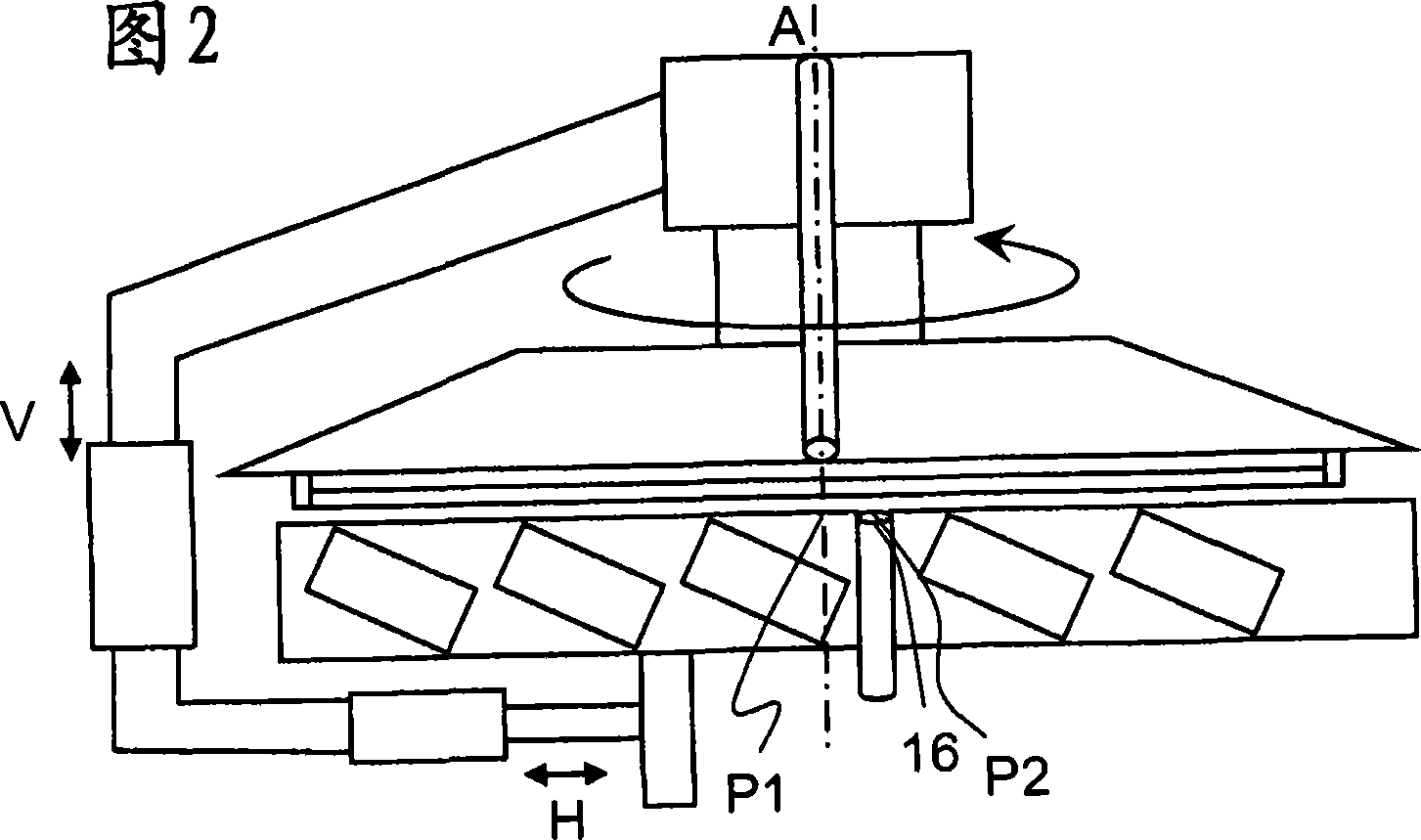

[0039] Fig. 1 shows a schematic diagram of an apparatus 1 according to an embodiment of the present invention.

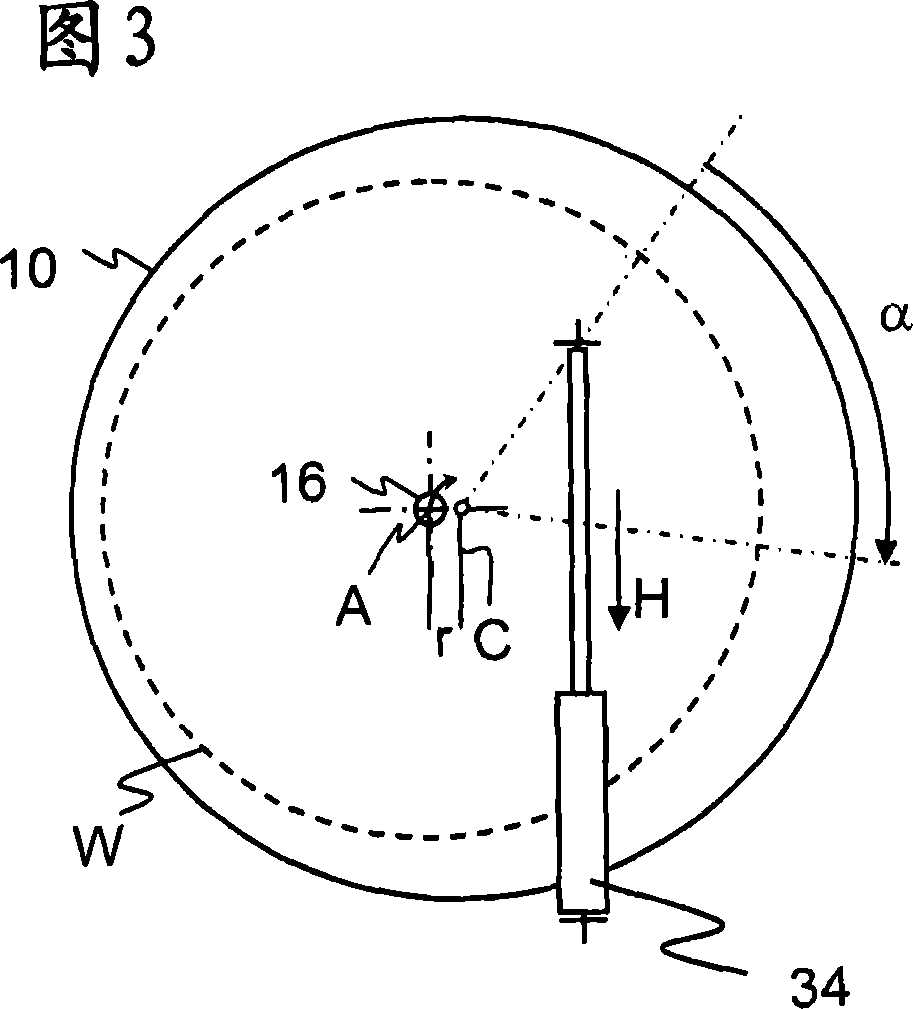

[0040] A rotary chuck 25 for rotatably holding a wafer W is mounted in a suspended state so as to hold the wafer W thereunder. The spin chuck 25 includes gripping pins 22 for securely gripping the wafer W at the edge of the wafer. The clamp pins can be moved eccentrically or tilted for clamping and releasing the wafer W. The mechanism (not shown) for moving the clamping needle may be similar to that disclosed in US Patent No. 4,903,717. The spin chuck 25 further includes a chuck plate 20 having a flat surface 20s parallel to and overlapping a wafer being processed. The plane 20s has a dispensing opening 26 at its center for receiving a fluid nozzle. The rotary chuck 25 is mounted via a coaxial hollow shaft to a hollow shaft motor 37 . The swivel chuck 25 rotates about this hollow shaft and an axis of rotation A of the swivel chuck 25 perpendicular to the plane 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com