Intelligent variable-power temperature-control concrete wall heat preservation formwork for winter construction

A thermal insulation formwork and variable power technology, which is applied in the direction of formwork/formwork components, thermometers, thermometer parts, etc., can solve problems such as the inability to realize the recycling of thermal insulation components, improve reliability and stability, reduce construction difficulty, The effect of advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

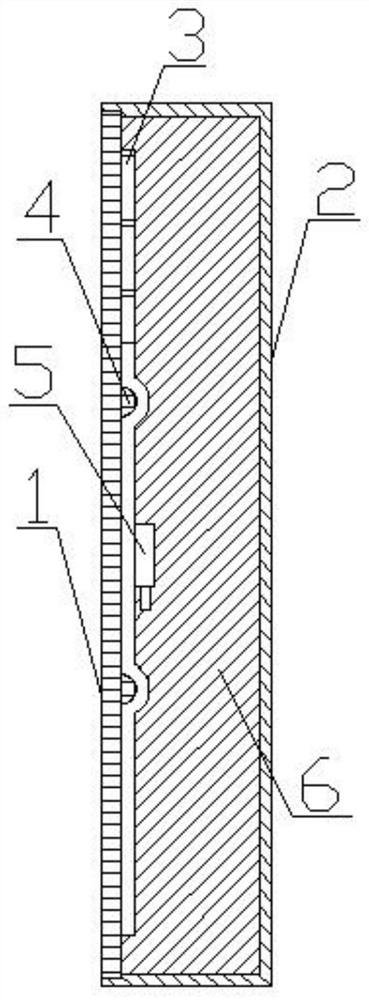

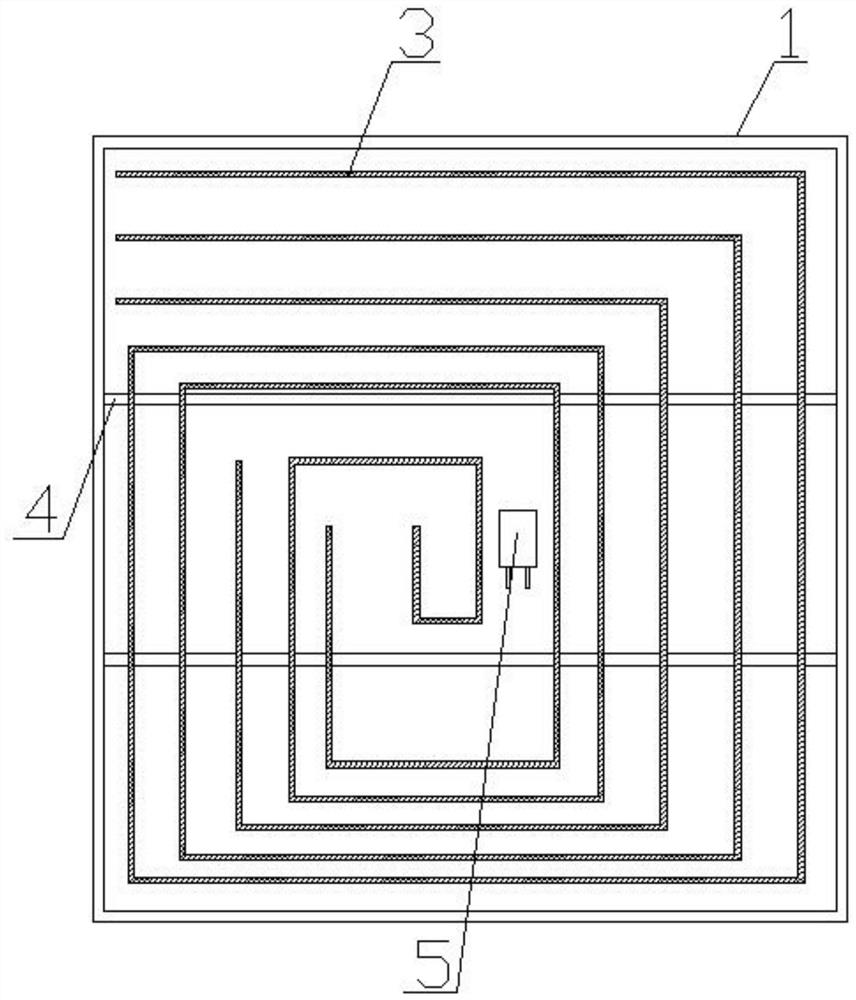

[0024] as attached figure 1 And attached figure 2 Shown: a thermal insulation structure for concrete wall construction in winter, including an aluminum panel 1 and a back panel 2 embedded in the aluminum panel 1, the aluminum panel 1 is made of aluminum material, which is more durable than other materials Good heat storage capacity; the aluminum panel 1 and the back panel 2 form a closed inner cavity, and the inner side of the aluminum panel 1 is equidistantly distributed with four aluminum keels 4, and each aluminum keel 4 is connected to the aluminum panel 1 screw connection so as to support the aluminum panel 1 and improve the strength of the aluminum panel 1 at the same time. A plurality of electric heating bodies 3 are equidistantly distributed on the aluminum panel 1. In this embodiment, three electric heating bodies 3 are used. Each electric heating body 3 adopts an electric heating cable. The power of the three electric heating bodies 3 is respectively 10W, 20W and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com