Semi-grouting sleeve without steel bar connecting threaded holes

A semi-grouting sleeve and threaded hole technology, which is applied to structural elements, building components, building reinforcements, etc., can solve problems such as complex structures, achieve the effects of increasing area, improving stress conditions, and firm and convenient connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

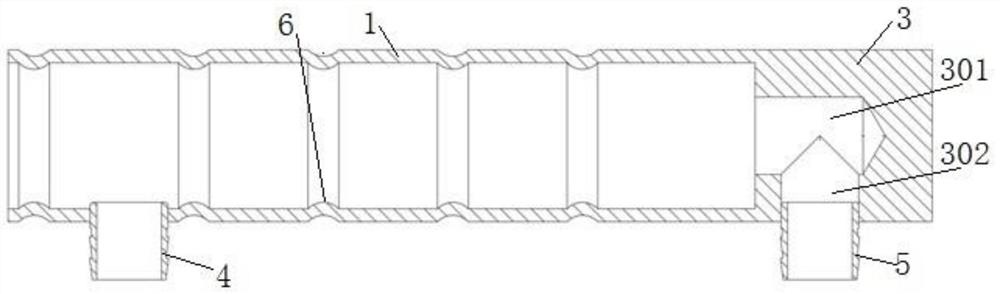

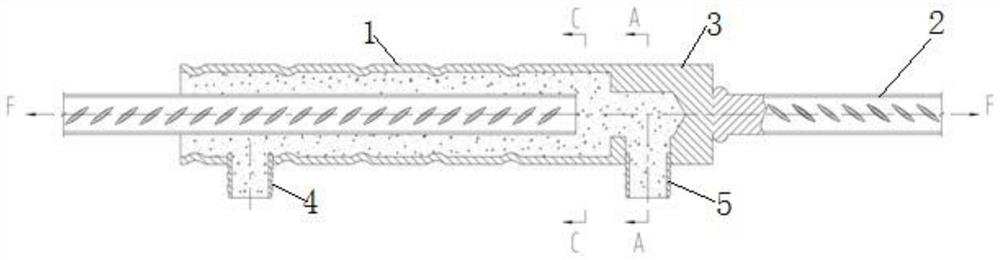

[0030] like figure 1 and figure 2 As shown, a half-grouting sleeve without steel bar connecting threaded holes, including a half-grouting sleeve grouting section 1, a half-grouting sleeve steel connection section 3, a grouting nozzle 4 and a grouting nozzle 5, and the half-grouting sleeve grouting section The outer periphery of 1 is provided with the grouting nozzle 4; the semi-grouting sleeve reinforcement connecting section 3 is provided with an axial blind hole 301 and a radial grouting hole 302, and the axial blind hole 301 and the radial row The slurry holes 302 are arranged vertically and through each other, and the slurry discharge nozzle 5 is arranged at the radial slurry discharge holes 302 . The inner diameters of the axial blind hole 301 and the radial slurry discharge hole 302 are set to be the same.

[0031] The present invention cancels the thread of the half-grouting sleeve part connected with the reinforcing bar, and uses it as the blind hole end of the rein...

Embodiment 2

[0043] In this embodiment, the dangerous section at the pulp discharge is analyzed.

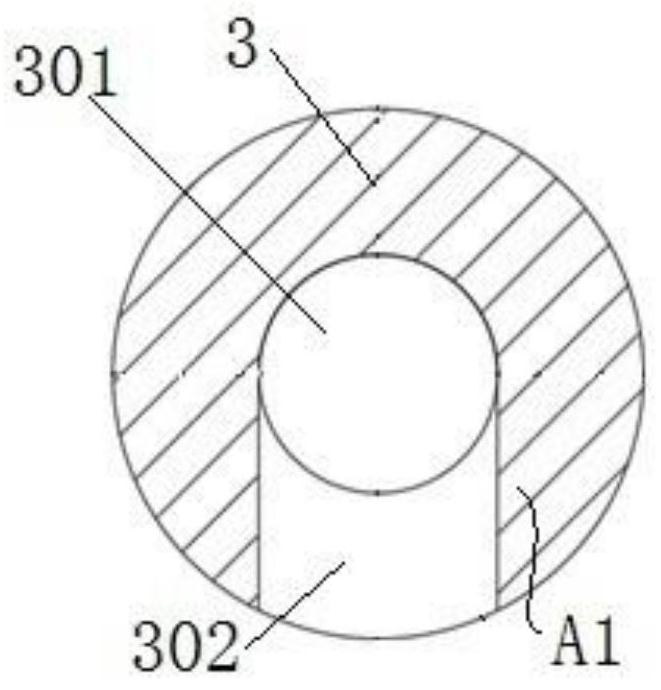

[0044] like figure 2 and image 3 As shown, taking a steel pipe with an outer diameter of 40 mm and a wall thickness of 3 mm as an example, the prepared semi-grouting sleeve grouting section 1 has an outer diameter of 40 mm and a wall thickness of 3 mm. The connection setting of the semi-grouting sleeve steel bar connecting section 3 of the grouting hole 302, the diameters of the axial blind hole 301 and the radial grouting hole 302 are both 18 mm, and the dangerous section is A-A under the action of the tension F, which is located in the half-grouting sleeve On the connection section 3 of the steel bar, the area of the dangerous section is A1.

[0045] like figure 2 and Image 6 As shown, under the action of tension F, the dangerous cross-section C-C, the cross-sectional area is A3.

[0046] like Figure 4 and Figure 5 As shown, the half-grouting sleeve is a conventional structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com