Antibacterial non-woven fabric for mask and preparation method of antibacterial non-woven fabric

A non-woven fabric and mask technology, which is applied to the field of antibacterial non-woven fabrics for masks and their preparation, can solve the problems of the decline of the antibacterial effect of masks, the analysis of antibacterial components, and the inability to kill bacteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An antibacterial nonwoven fabric for a mask, comprising the following raw materials in parts by weight: 80 parts of PET polyester chips, 5 parts of antibacterial agent, 1 part of lubricant, and 5 parts of plasticizer;

[0033] Step S1: adding PET polyester chips, antibacterial agent, lubricant, and plasticizer into the extruder, and melt extruding to obtain polyester fiber;

[0034] Step S2: Weaving the polyester fiber into a cloth to prepare an antibacterial non-woven fabric for a mask.

[0035] Described antibacterial agent is made by following steps:

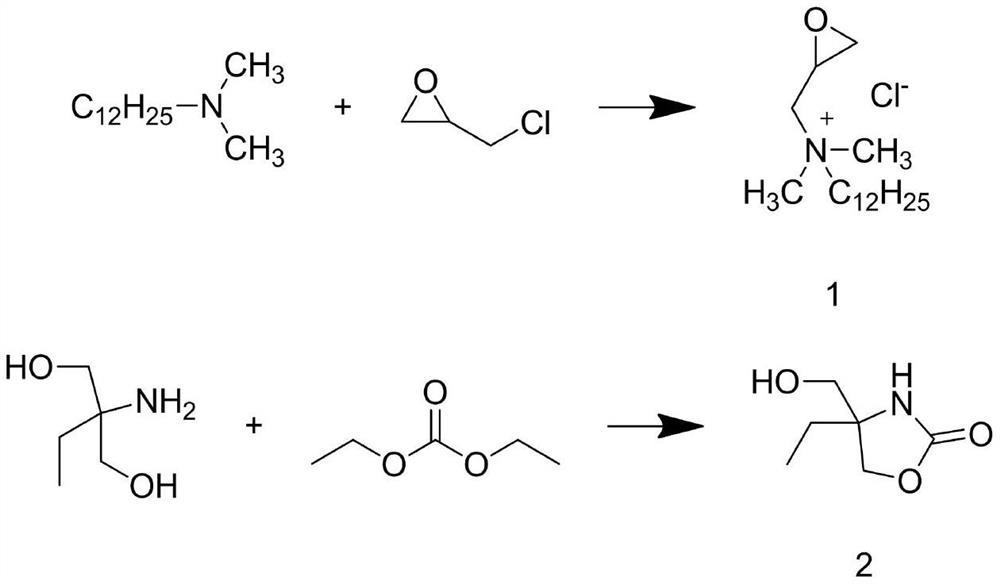

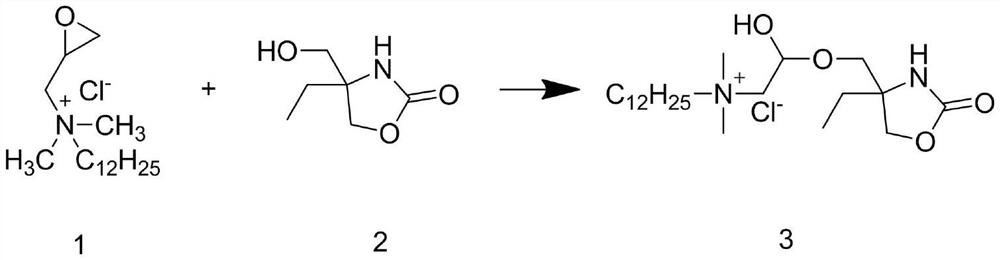

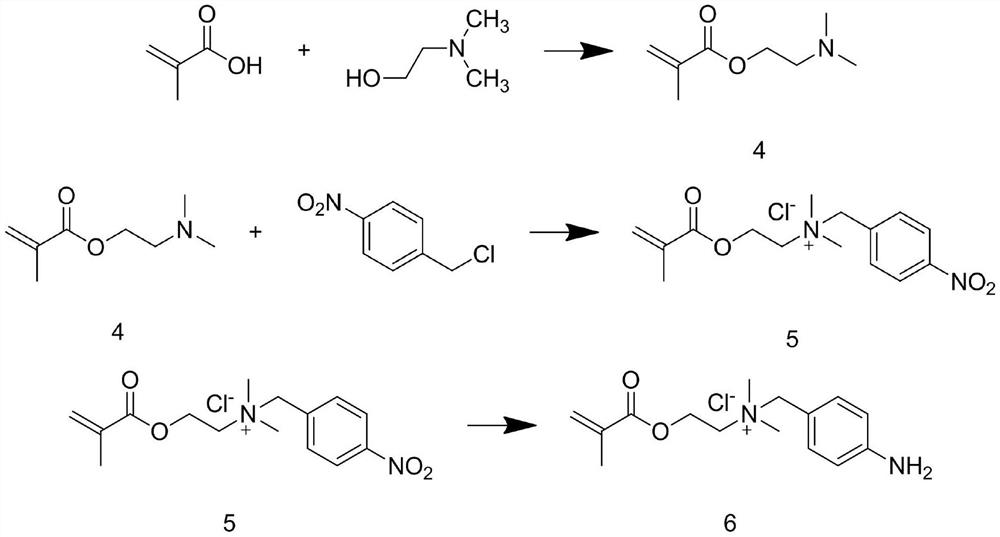

[0036] Step A1: Add epichlorohydrin and N,N-dimethyldodecyl tertiary amine into the reaction kettle, and react for 2 hours at a speed of 200r / min and a temperature of 55°C to obtain an intermediate 1. Add diethyl carbonate, 2-amino-2-ethyl-1,3-propanediol, and sodium methoxide into the reaction kettle, and carry out a reflux reaction for 35 hours at a speed of 150r / min and a temperature of 115°C. Prepare intermediate...

Embodiment 2

[0040] An antibacterial nonwoven fabric for a mask, comprising the following raw materials in parts by weight: 85 parts of PET polyester chips, 7 parts of antibacterial agent, 2 parts of lubricant, and 6 parts of plasticizer;

[0041] Step S1: adding PET polyester chips, antibacterial agent, lubricant, and plasticizer into the extruder, and melt extruding to obtain polyester fiber;

[0042] Step S2: Weaving the polyester fiber into a cloth to prepare an antibacterial non-woven fabric for a mask.

[0043] Described antibacterial agent is made by following steps:

[0044] Step A1: Add epichlorohydrin and N,N-dimethyldodecyl tertiary amine into the reaction kettle, and react for 2 hours at a speed of 200r / min and a temperature of 65°C to obtain an intermediate 1. Add diethyl carbonate, 2-amino-2-ethyl-1,3-propanediol, and sodium methoxide into the reaction kettle, and carry out a reflux reaction for 40 hours at a speed of 200r / min and a temperature of 115°C. Prepare intermediate ...

Embodiment 3

[0048] An antibacterial nonwoven fabric for a mask, comprising the following raw materials in parts by weight: 90 parts of PET polyester chips, 8 parts of antibacterial agent, 2 parts of lubricant, and 7 parts of plasticizer;

[0049] Step S1: adding PET polyester chips, antibacterial agent, lubricant, and plasticizer into the extruder, and melt extruding to obtain polyester fiber;

[0050] Step S2: Weaving the polyester fiber into a cloth to prepare an antibacterial non-woven fabric for a mask.

[0051] Described antibacterial agent is made by following steps:

[0052] Step A1: Add epichlorohydrin and N,N-dimethyldodecyl tertiary amine into the reaction kettle, and react for 4 hours at a speed of 300r / min and a temperature of 55°C to obtain an intermediate 1. Add diethyl carbonate, 2-amino-2-ethyl-1,3-propanediol, and sodium methoxide into the reaction kettle, and carry out reflux reaction for 35 hours under the conditions of rotation speed of 150r / min and temperature of 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com