Movable temperature control sand bath beam source furnace and mounting and coating method thereof

A beam source furnace and sand bath technology, applied in the field of vacuum coating, can solve the problems of compatibility and universality of use, strict requirements on location and interface, affecting the effective use of medicines, etc., and achieve fast and good coating, high installation efficiency, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

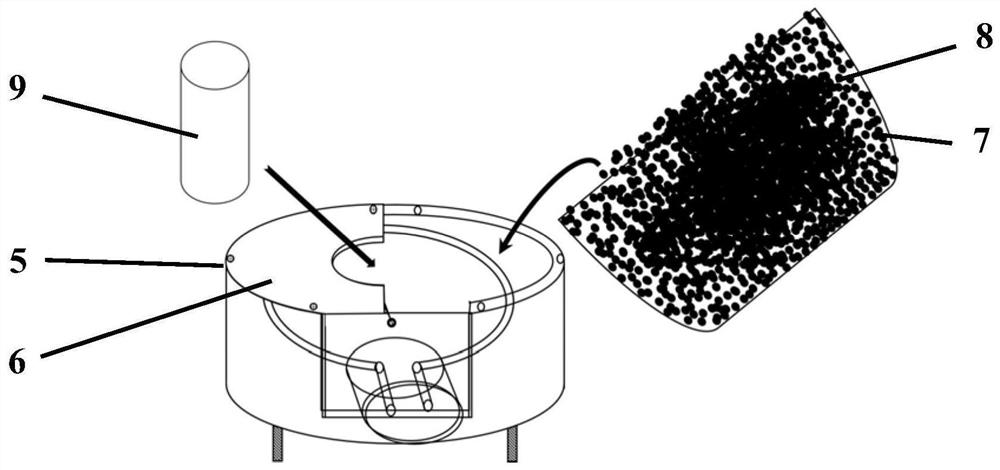

[0043] The present invention will be described in detail below with reference to the accompanying drawings and examples.

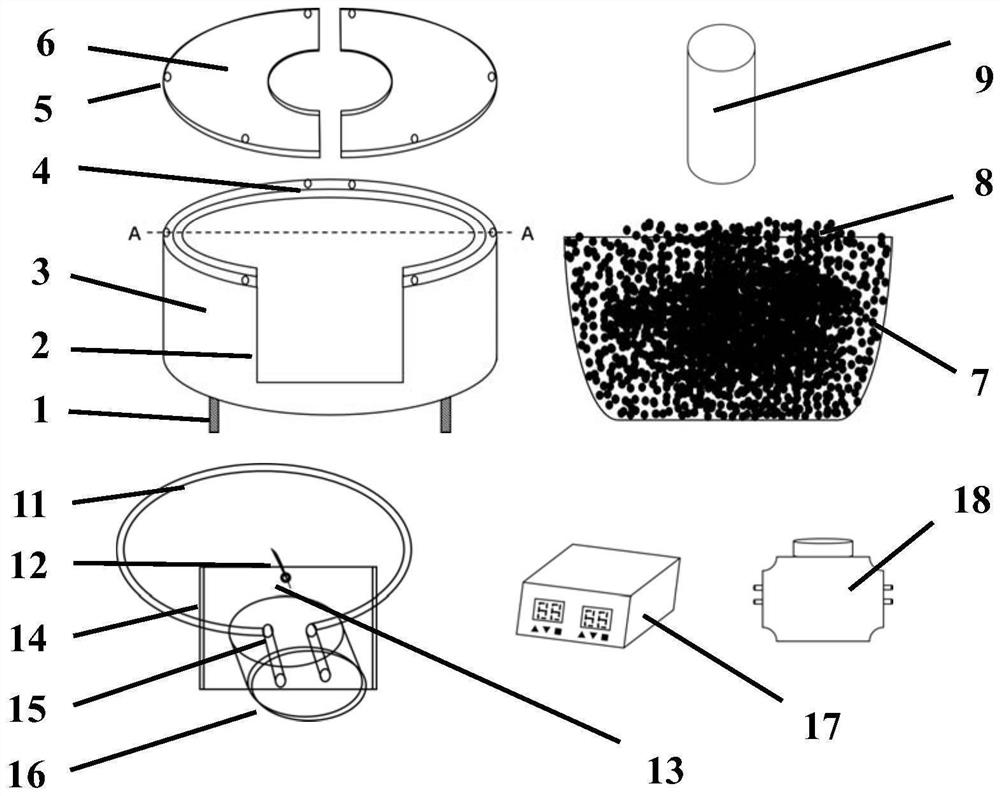

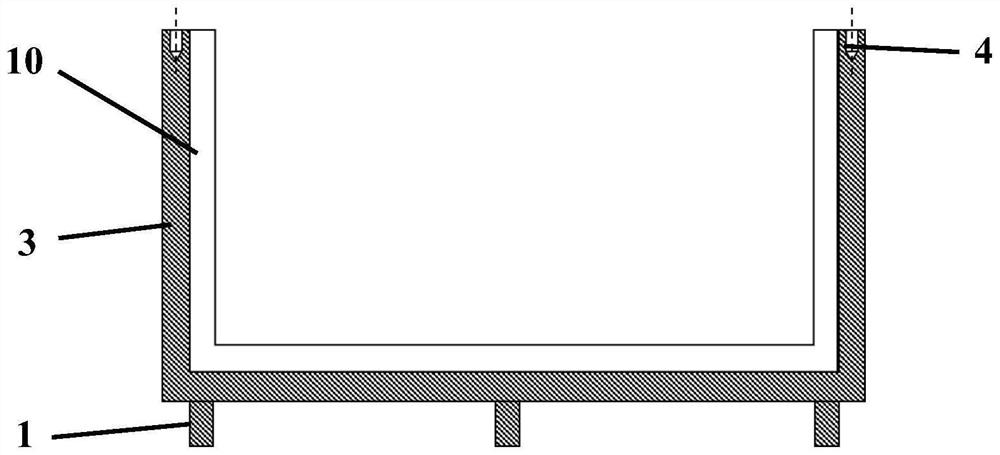

[0044] The present invention provides a movable temperature-controlled sand bath beam source furnace, comprising a beam source furnace bottom foot 1, a beam source furnace body 3, a beam source furnace body cover plate 6, a vessel 7 for filling sand, filling sand 8, Crucible 9, vacuum insulation liner 10, heating ring 11, temperature probe 12, high temperature resistant ceramic plate 14, electrode terminal insulating ceramic protective cover 16, temperature controller 17 and voltage regulator 18.

[0045] Wherein, the number of legs 1 at the bottom of the beam source furnace is 3, and the three legs of the beam source furnace body are triangularly distributed at the bottom of the beam source furnace body 3 .

[0046] In this embodiment, the beam source furnace body 3 is a cylinder made of high temperature resistant ceramics. There is an opening on the sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com