Acrylate adhesive

An acrylate and acrylate-based technology, applied in adhesives, polymer adhesive additives, non-polymer organic compound adhesives, etc., can solve problems such as easy cracking and degumming, and different thermal expansion coefficients between cured products and acrylic. Achieve high heat resistance, easy glue application and prolong pot life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

[0042] Embodiment 1-7: an acrylic adhesive, comprising component A and component B, the mass ratio of component A and said component B is 20:1.

[0043] The formulation of component A is shown in Table 1. The preparation method of component A is: mix the formula amount of acrylate monomer and thickener, stir and disperse evenly, add the formula amount of stabilizer, accelerator, ultraviolet absorber and other formula components, stir and disperse evenly, Just remove the air bubbles.

[0044] Component B includes 95wt% of plasticizer and 5wt% of initiator; the plasticizer is selected from phthalates; the initiator is selected from benzoyl peroxide. The preparation method of component B is as follows: stir and disperse the plasticizer in the formulated amount evenly, add the initiator in the formulated amount, stir and disperse evenly, and remove air bubbles.

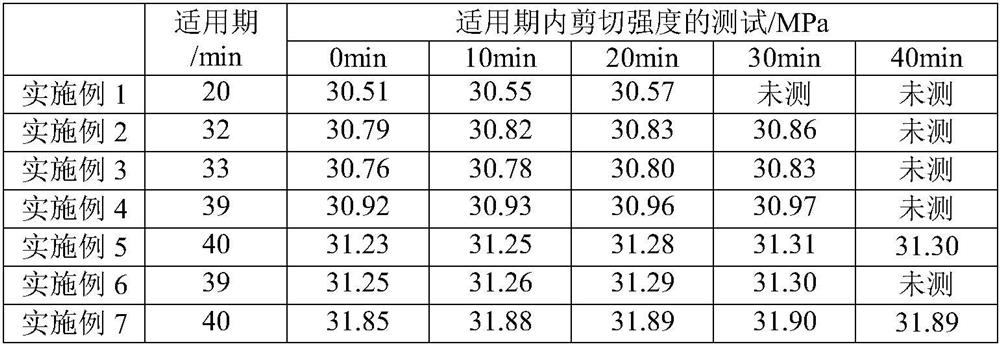

[0045] Component A formula information (unit: parts by mass) of the embodiment 1-7 of table 1

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com