Safety cloth winding and packaging auxiliary equipment with automatic carding effect

An auxiliary equipment and safety technology, which is applied in the field of cloth winding and packaging auxiliary equipment, can solve the problems that affect the uniformity of the equipment's winding of the cloth, the inability to detect the deviation of the winding axis of the equipment, and affect the working efficiency of the equipment, so as to improve the packaging quality and improve the efficiency of the equipment. The effect of maintenance and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

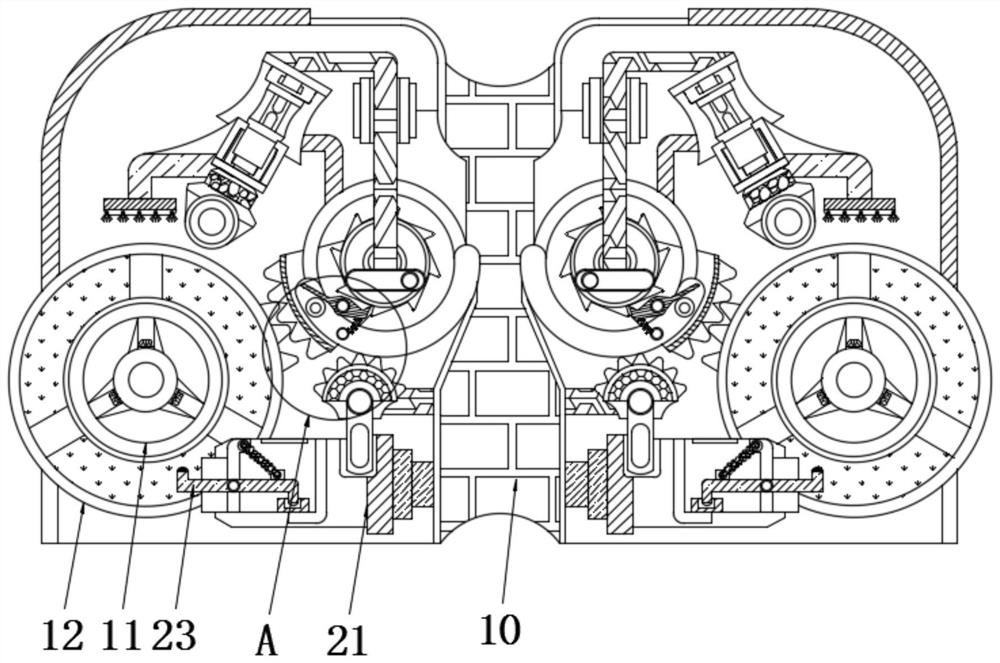

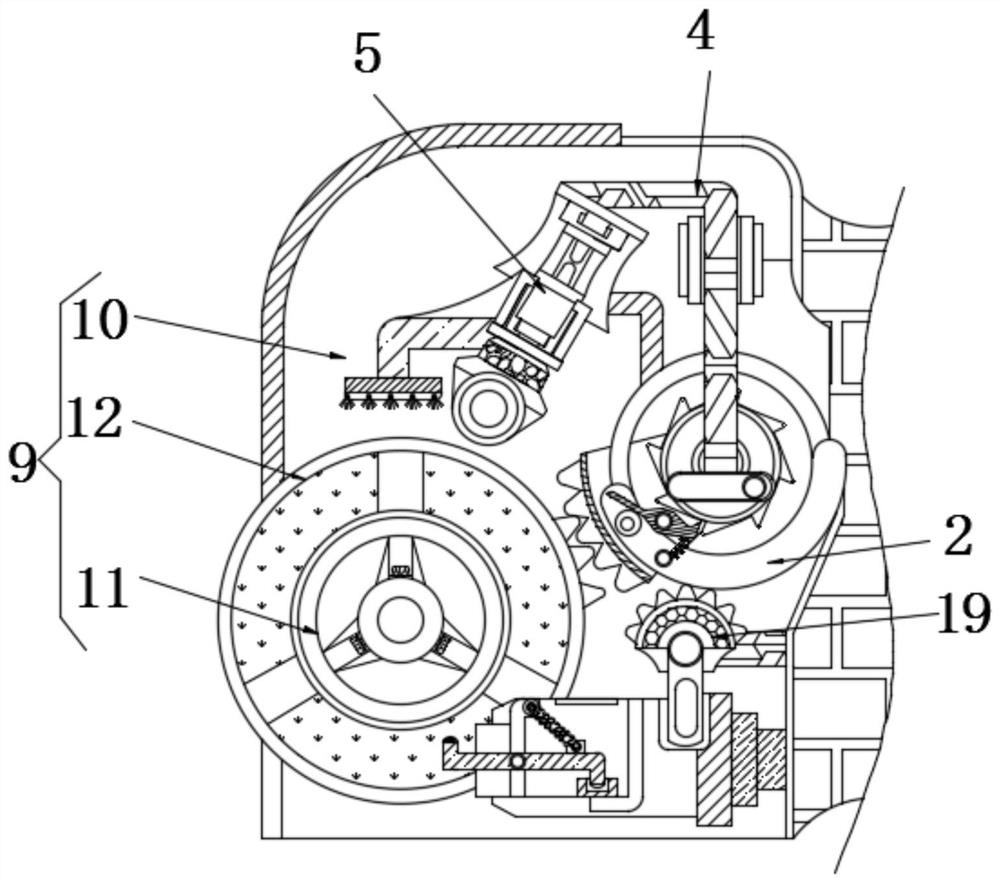

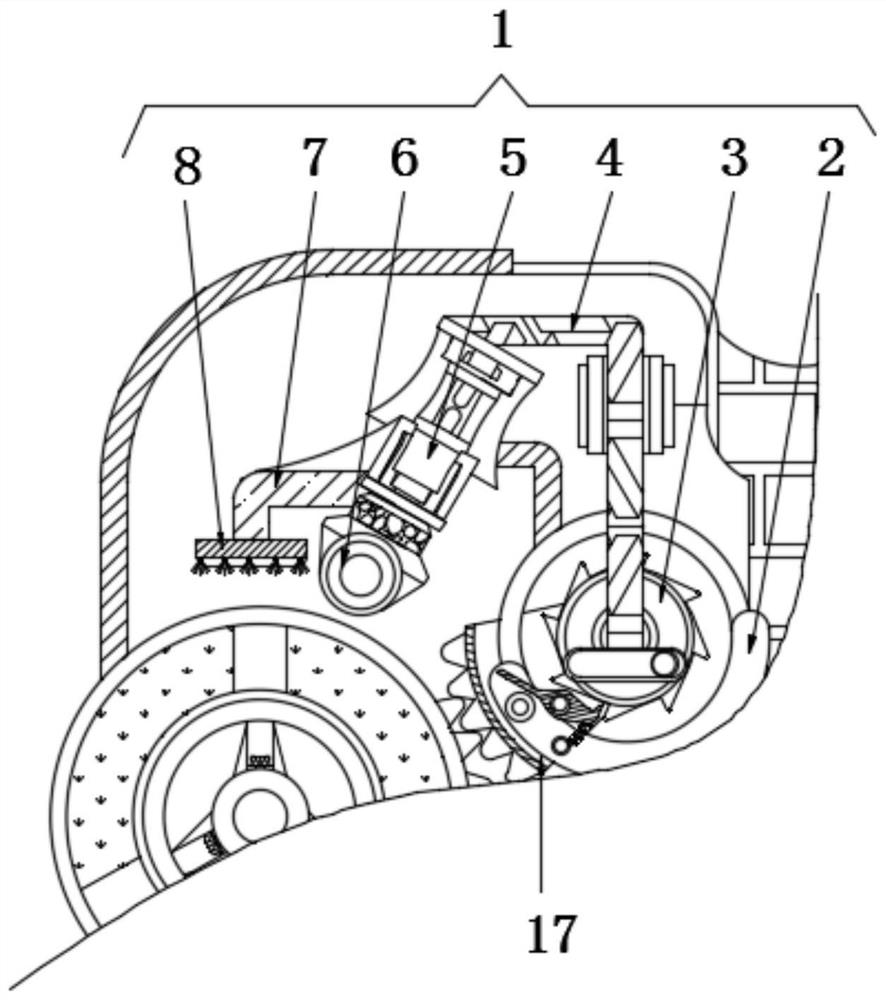

[0023] A safety cloth winding and packaging auxiliary equipment with automatic carding function, including a carding mechanism 1 and a detection mechanism 18, the carding mechanism 1 includes a fixed arc plate 2, and the internal rotation of the fixed arc plate 2 is connected with a special-shaped rotating shaft 3, and the special-shaped rotating shaft 3 The front surface of the shaft is movably connected with a transmission link 4, and the end of the transmission link 4 away from the special-shaped rotating shaft 3 is fixedly connected with a support plate 5, and the side of the support plate 5 away from the transmission link 4 is rotatably connected with a flattening wheel 6. The left side of the plate 5 is fixedly connected with an angle connecting rod 7 , and the end of the angle connecting rod 7 away from the support plate 5 is fixedly connected with a carding plate 8 .

[0024] Also includes a supply mechanism 9, the supply mechanism 9 includes a winding wheel 11, the ins...

specific Embodiment 2

[0027] A safety cloth winding and packaging auxiliary equipment with automatic carding function, including a carding mechanism 1 and a detection mechanism 18, the carding mechanism 1 includes a fixed arc plate 2, and the internal rotation of the fixed arc plate 2 is connected with a special-shaped rotating shaft 3, and the special-shaped rotating shaft 3 The front surface of the shaft is movably connected with a transmission link 4, and the end of the transmission link 4 away from the special-shaped rotating shaft 3 is fixedly connected with a support plate 5, and the side of the support plate 5 away from the transmission link 4 is rotatably connected with a flattening wheel 6. The left side of the plate 5 is fixedly connected with an angle connecting rod 7 , and the end of the angle connecting rod 7 away from the support plate 5 is fixedly connected with a carding plate 8 .

[0028] The detection mechanism 18 includes a V-shaped gear 19, the front surface of the V-shaped gear ...

specific Embodiment 3

[0031] A safety cloth winding and packaging auxiliary equipment with automatic carding function, including a carding mechanism 1 and a detection mechanism 18, the carding mechanism 1 includes a fixed arc plate 2, and the internal rotation of the fixed arc plate 2 is connected with a special-shaped rotating shaft 3, and the special-shaped rotating shaft 3 The front surface of the shaft is movably connected with a transmission link 4, and the end of the transmission link 4 away from the special-shaped rotating shaft 3 is fixedly connected with a support plate 5, and the side of the support plate 5 away from the transmission link 4 is rotatably connected with a flattening wheel 6. The left side of the plate 5 is fixedly connected with an angle connecting rod 7 , and the end of the angle connecting rod 7 away from the support plate 5 is fixedly connected with a carding plate 8 .

[0032] Also includes a supply mechanism 9, the supply mechanism 9 includes a winding wheel 11, the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com