Surface film laminating device for paper packaging box processing

A coating device and packaging box technology, which is applied in the field of surface coating devices for paper packaging box processing, can solve the problems of affecting the quality of packaging boxes in the later period, warping in the later period, and the inability to coat the surface of the film, etc., to ensure the quality of the coating , Simple operation, easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

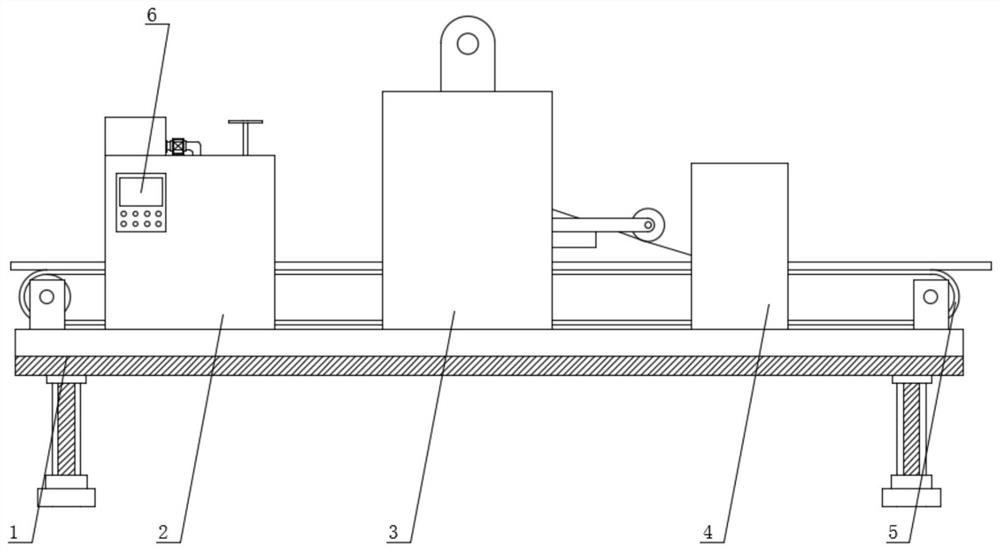

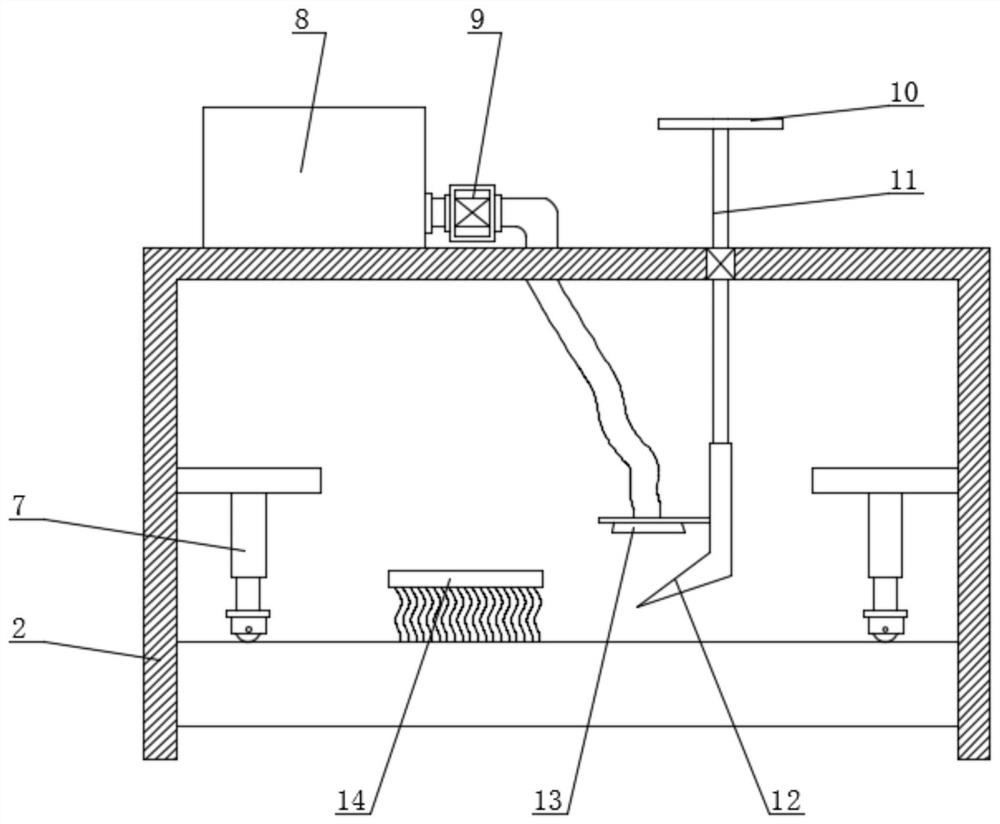

[0038] Embodiment one, with reference to figure 1 , 2 and Figure 6 , a surface coating device for paper packaging box processing, including a device body 1, a transmission mechanism 5 is installed on the top surface of the device body 1, a cleaning box 2 is installed on the top of the device body 1, and the inner wall of the cleaning box 2 The surface is located above the transmission mechanism 5 and is provided with a brush plate 14. The top of the cleaning box 2 is spirally connected with a first screw 11, and the bottom end of the first screw 11 is provided with a first scraper 12. The first screw 11 The top end is provided with a first adjusting wheel 10, the surface of the first scraper 12 is provided with a dust cover 13 through a connecting rod, and a collection box 8 is installed on the top surface of the cleaning box 2, and one end of the collection box 8 passes through a pipe and a blower. 9 connection, one end of the blower 9 passes through the top surface of the...

Embodiment 2

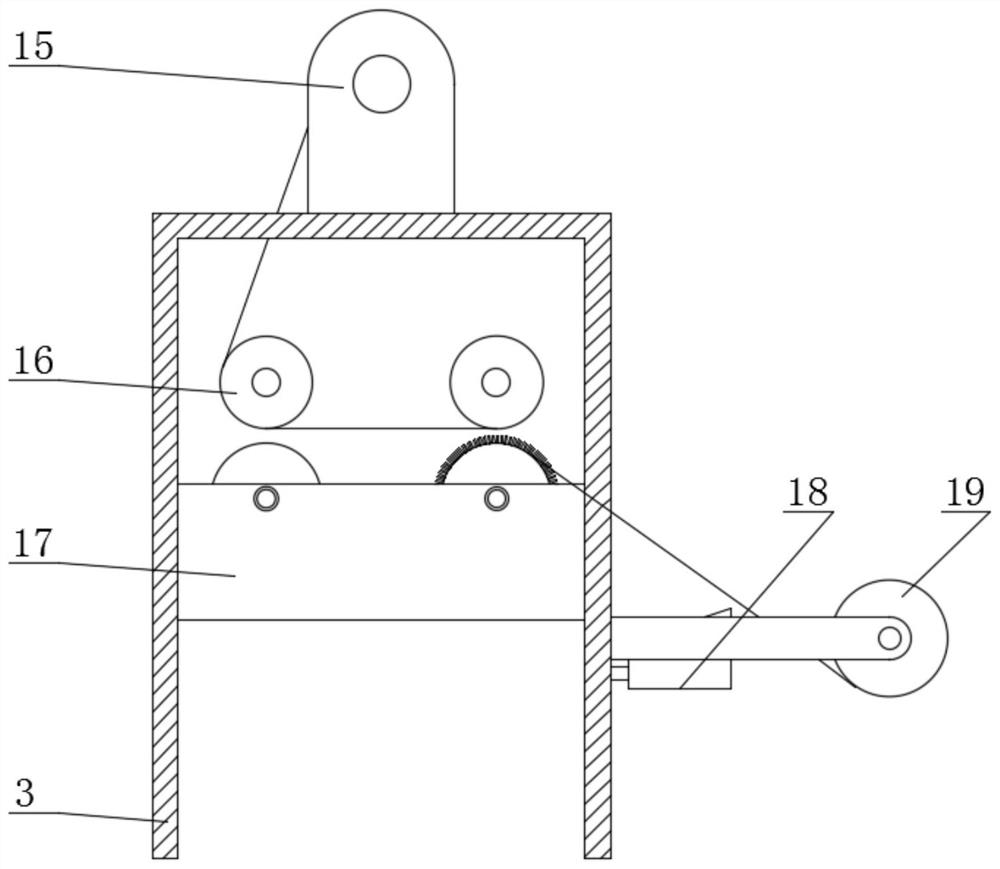

[0039] Embodiment two, refer to figure 1, 3 , 4, and Figure 5 , the top surface of the device body 1 is located on one side of the cleaning box 2 to be provided with a glue application box 3, the top surface of the glue application box 3 is provided with a film release frame 15, and a glue box 17 is installed inside the glue application box 3, so The inside of the glue box 17 is provided with a gluing roller 20, one side of the gluing roller 20 is provided with a brush roller 21, the inside of the gluing box 3 is provided with a first traction roller 16, and the top of the gluing box 3 is provided with a There is a way out, the surface of the gluing box 3 is provided with a second traction roller 19 through a connecting rod, the surface of the connecting rod is provided with a collecting tank 18, and the top of the collecting tank 18 is provided with a second scraper 22, by setting The cooperating use of the gluing roller 20, the brush roller 21, the collection tank 18 and ...

Embodiment 3

[0040] Embodiment three, refer to figure 1 , 7 and Figure 8 , the top surface of the device body 1 is provided with a laminating box 4, the inside of the laminating box 4 is provided with a lower pressure roller 28, the top of the laminating box 4 is provided with an adjustment frame 27, and the top of the adjustment frame 27 is spirally Connected with a second screw 30, the bottom of the second screw 30 is connected to the top of the coating box 4, the top of the second screw 30 is provided with a second adjustment wheel 31, and the inner bottom of the adjustment frame 27 is vertically provided with Measuring rod 29, the top surface of the film coating box 4 is provided with a relief hole, the bottom end of the adjustment frame 27 is provided with an upper pressure roller 26, and the measuring rod 29 is provided with two, and the two measuring rods 29 are installed symmetrically At the inner bottom of the adjustment frame 27, by setting the adjustment frame 27, the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com