Lithocarpus litseifolius extract granules as well as preparation method and application thereof

A technology for extracts of Cordyceps sinensis and extract, which is applied to the field of extract particles of Cordyceps sinensis and their preparation, can solve the problems of not being able to give full play to the efficacy of the medicinal components of Cordyceps sinensis, and achieve the effects of ensuring efficacy, improving cleanliness, and increasing cleaning strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A wooden leaf leaf extract particle, formulation includes: wood leaf leaf extract and excipients; the mass percentage of each component is: 65% of wooden leaf leaf extracts and 35% excipients.

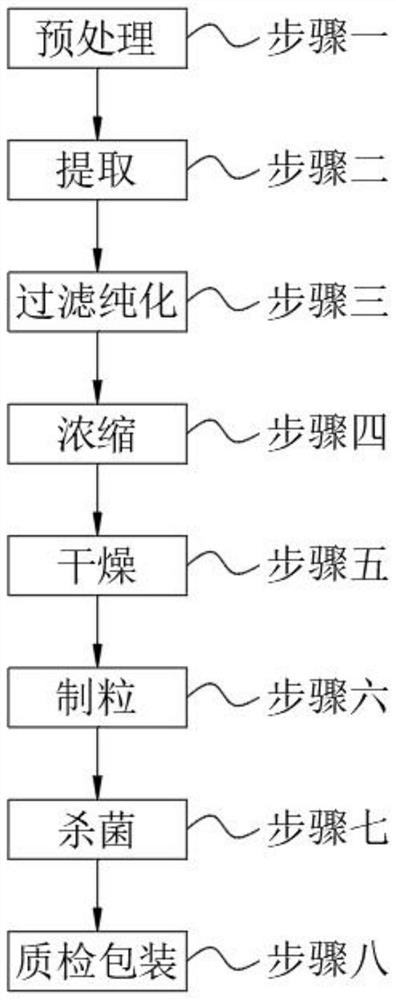

[0026] Method for preparing a wooden leaf leaf extract particle, including steps 1, raw material pretreatment; step two, extraction; step three, filtrate purification; step four, concentrate; step five, dry; step six, granulation; step Seven, sterilization; step eight, quality inspection packaging;

[0027] In the above steps, the appropriate amount of wooden ginger leaf releasing leaf, the destination, placed in the rinse machine, and add the appropriate amount of polyzyme cleaner, soak for 30 minutes, repeated rolling 25 min, then rinse it once, drain, Get a clean blade, dry it with a blast dryer, and the pulverizer is pulverized to 120 mesh to get the wood leaf cob powder.

[0028] In step two, in step two, ultrasonic water absorption is performed, and the wood leaf powder obtain...

Embodiment 2

[0037] A wooden leaf leaf extract particle, formulation includes: wood leaf leaf extract and excipients; the mass percentage of each component is: 75% of wooden leaf leaf extracts and 25% excipients.

[0038] Method for preparing a wooden leaf leaf extract particle, including steps 1, raw material pretreatment; step two, extraction; step three, filtrate purification; step four, concentrate; step five, dry; step six, granulation; step Seven, sterilization; step eight, quality inspection packaging;

[0039] In the above steps, the appropriate amount of wooden ginger leafkin leaf, the destination, placed in the rinsing machine, and add the appropriate amount of polyzyme cleaner, soak 45min, repeated rolling 30 min, then rinse it once, drain, Get a clean blade, dry it with a blast dryer, and the pulverizer is pulverized to 160 mesh to get the wood leaf cob powder.

[0040] In step two, in step two, ultrasonic water absorption is performed, and the wood leaf powder obtained in step one...

Embodiment 3

[0049] A wood-leaf ginger extract Ke Ti particles, the formulation comprising: Litsea Keti leaf extract and excipients; mass percentage of the components are: 85% Litsea Keti leaf extract and 15% excipients.

[0050] Method for preparing a wooden leaf leaf extract particle, including steps 1, raw material pretreatment; step two, extraction; step three, filtrate purification; step four, concentrate; step five, dry; step six, granulation; step Seven, sterilization; step eight, quality inspection packaging;

[0051] Wherein said step a, the appropriate amount of Litsea leaf picking Ke leaves, stems go, into the rinsing machine and an appropriate amount of a multi-enzyme detergent, soaking after 60min, rinsed repeatedly shaking 40min, then washed once with water, drained, cleansed blade, and then drying fan dryer, a grinder to 180 mesh, to obtain powder Litsea leaf Ke.

[0052] In step two, in step two, ultrasonic water absorption is performed, and the wood leaf powder obtained in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com