CT slip ring electric brush and forming method thereof

A technology for brush holders and slip rings, which can be used in the manufacture of slip rings, circuits, collectors, etc., and can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

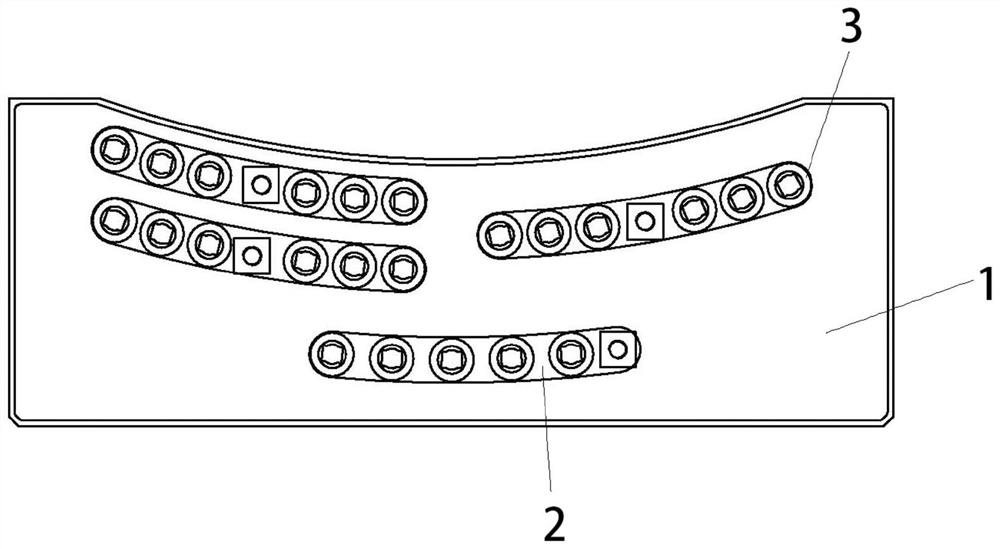

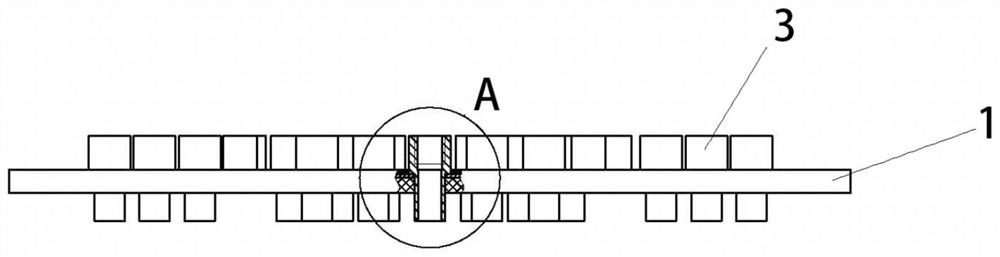

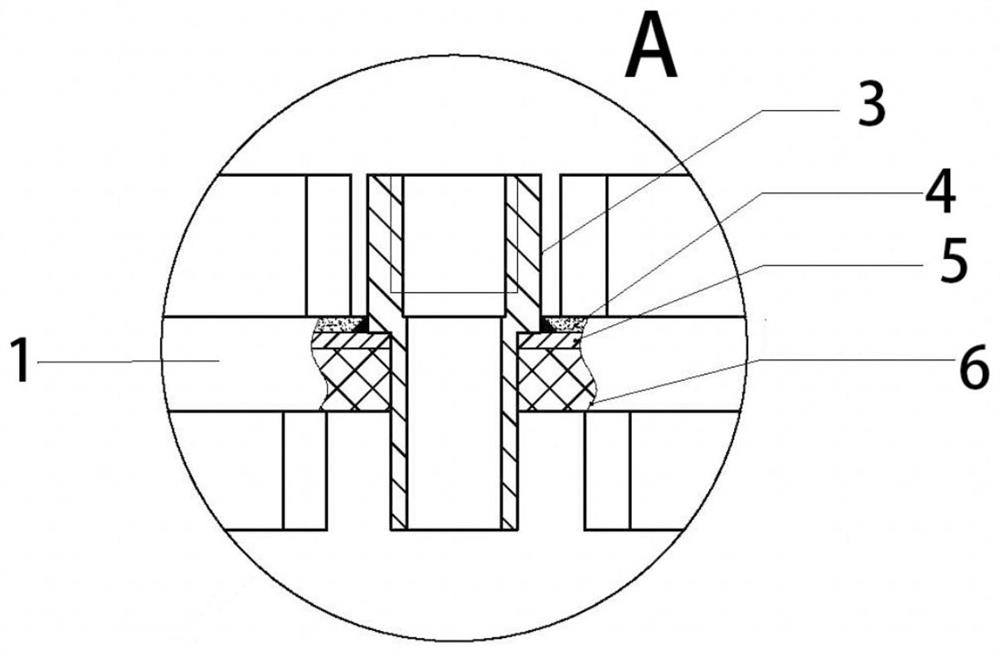

[0034] figure 1 , 2 , 3, a CT slip ring brush holder, including a frame body 1 and a brush holder 3, the frame body is cuboid, the frame body is provided with conductive channels 2, the conductive channels are provided with 4, and each conductive The shape of the channel is adapted to the shape of the conductive slip ring on the CT slip ring. The conductive channel is opened on one side of the frame body. The conductive channel is actually a groove opened on the side of the frame body, and the conductor is installed and placed in the groove.

[0035] The conductive channel is provided with a brush holder installation hole, the installation hole is set through the frame body, and each conductive channel is provided with 5 or 6 brush holder installation holes, wherein the brush holder is installed in each brush holder installation hole.

[0036] Among them such as figure 1 As shown, the positions of the 4 conductive channels are adapted to the shape of the conductive slip ring...

Embodiment 2

[0038] Embodiment 2: A method for forming a CT slip ring brush holder, comprising the following steps:

[0039] (1) Cut the 8mm thick phenolic resin plate and the 2mm thick H59 copper plate into cuboids with equal length and width. (2) Apply 3M DP760 epoxy resin evenly on one side of the phenolic board, (3) Put the coated phenolic board and the copper board in a vacuum bag at the same time, and slide the copper board to the position aligned with the phenolic board while vacuuming And press the copper plate to distribute the epoxy resin evenly, take out the parts and wait for the epoxy resin to cure. (4) Then mill the required conductive channel in the installation hole of the brush holder. Air blowing is used for cooling during milling and cutting fluid cannot be used. (5) Insert the brush holder into the hole, use induction heating equipment to solder the brush holder and the copper plate, and control the welding temperature at 245±5°C by controlling the power and heating ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com