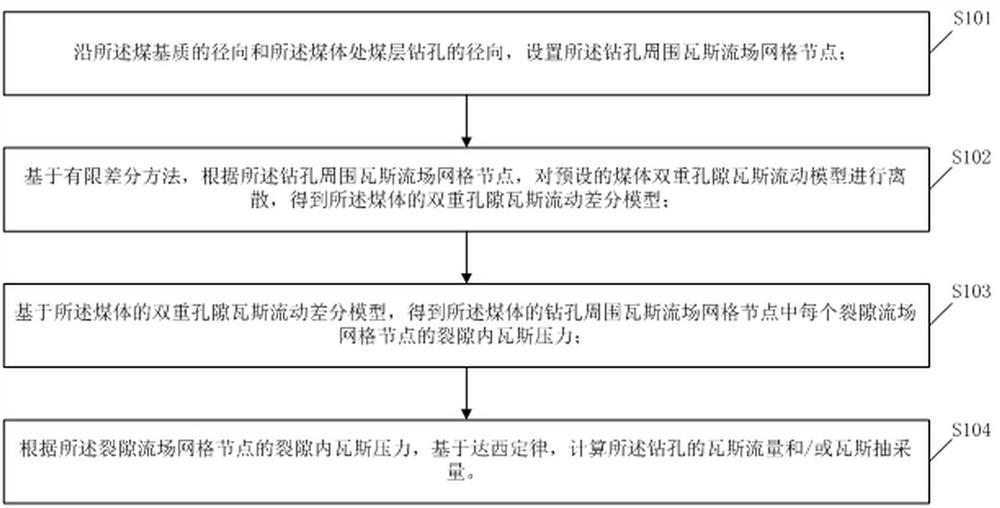

Method and system for predicting coalbed methane of double-pore coal body

A technology of double porosity and prediction method, which is applied in the direction of prediction, special data processing applications, instruments, etc., can solve the problems of manpower, time and economic cost, and the inability to directly and accurately predict the later production of coalbed methane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

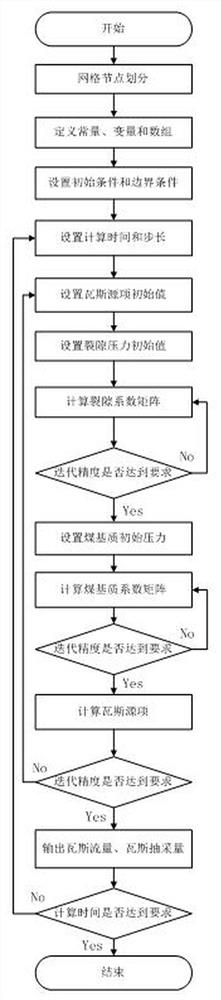

Embodiment Construction

[0055] The present application will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments. The various examples are provided by way of explanation of the application and do not limit the application. In fact, it will be apparent to those skilled in the art that modifications and variations can be made in the present application without departing from the scope or spirit of the application. For example, features illustrated or described as part of one embodiment can be used on another embodiment to yield yet another embodiment. Therefore, it is intended that this application cover such modifications and variations as come within the scope of the appended claims and their equivalents.

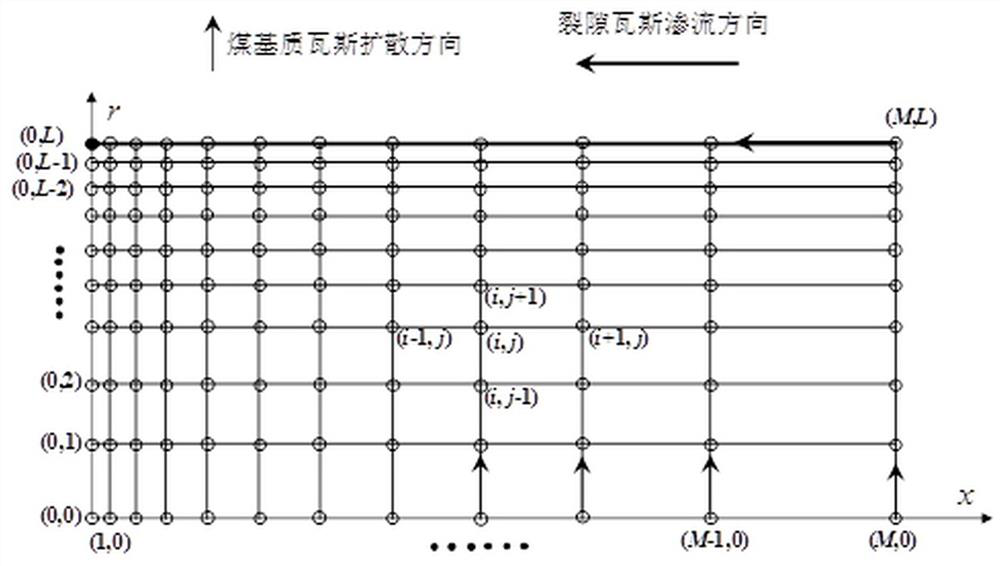

[0056] In the examples of this application, the coal matrix is an isotropic, average-valued porous medium sphere, and its porosity and diffusion coefficient are uniform and unaffected by changes in gas pressure in the coal matrix; the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com