TBM cutterhead vibration monitoring and evaluating method

An evaluation method and vibration monitoring technology, applied in the direction of measuring devices, measuring ultrasonic/sonic/infrasonic waves, special data processing applications, etc., can solve the problems of lack of vibration monitoring methods and vibration level measurement standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation of the present invention will be described in detail below in combination with the accompanying drawings and technical solutions, and the present invention will be further described.

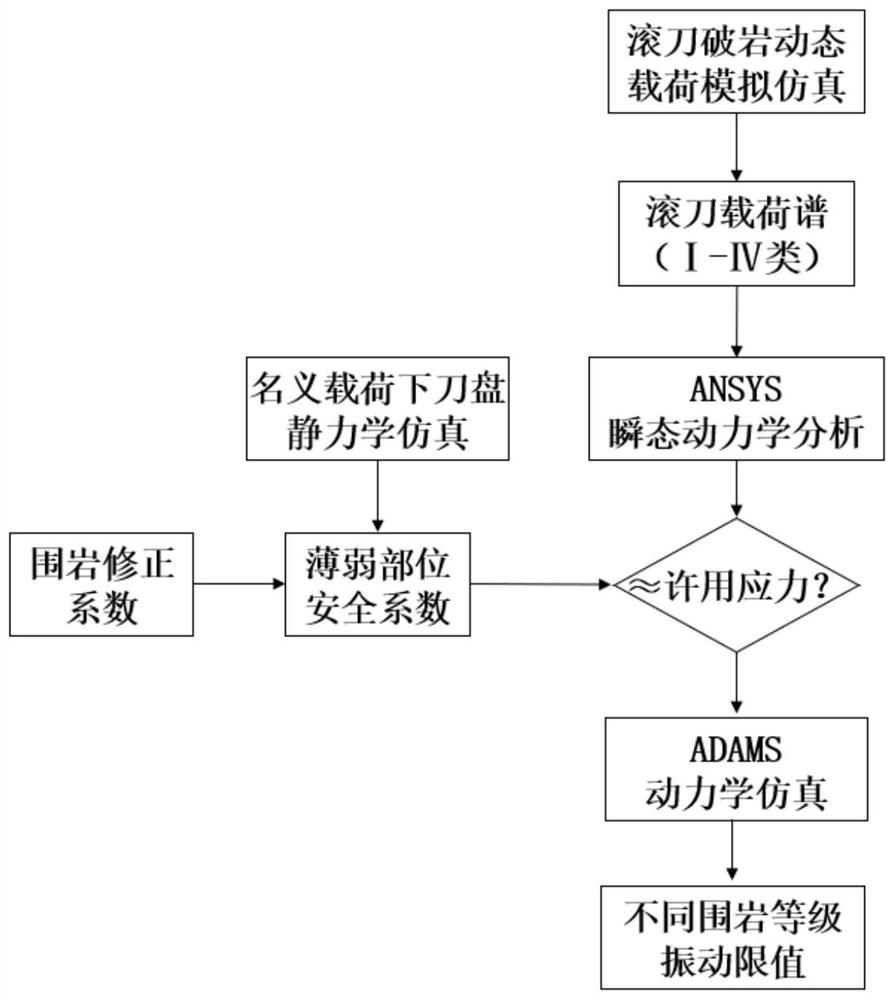

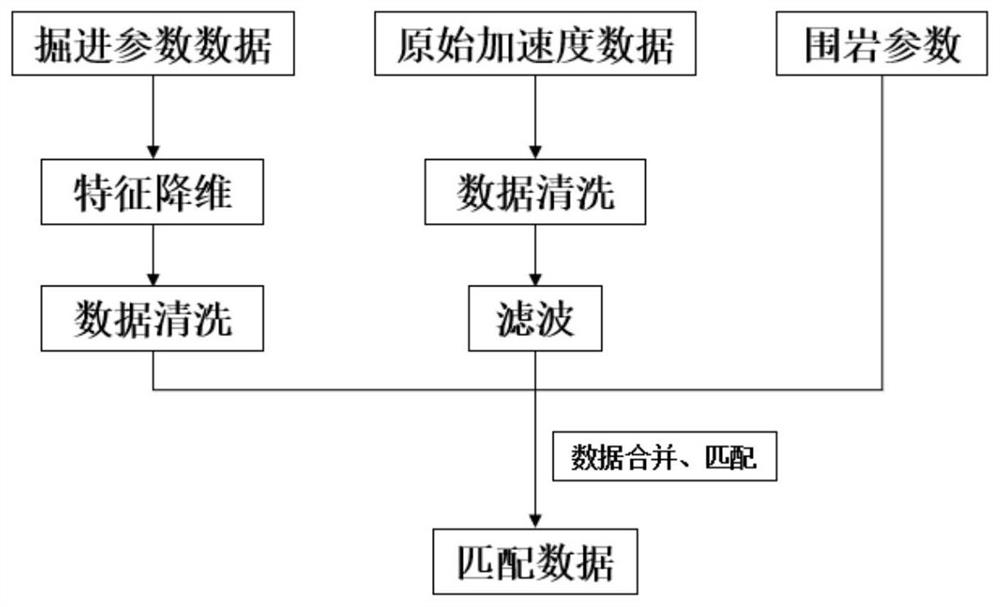

[0029] like figure 1 Shown is a flow chart of a TBM cutterhead vibration limit analysis method. Including the following steps: a), data preprocessing; b), external excitation research of TBM cutterhead; c), determination of allowable stress of cutterhead under different working conditions; d), cutterhead transient dynamics analysis; e), Dynamic Response Analysis of Cutterhead

[0030] TBM cutterhead vibration limit analysis method, the three-dimensional force of the hob under different compressive strength rock conditions is obtained through the hob-cutter rock breaking simulation, and is corrected by the actual measurement data on the construction site, which is used as the external excitation of the model to perform transient Dynamic analysis, and then meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com