A Highly Adaptable Stainless Steel Pipe Joint

A stainless steel pipe, adaptable technology, applied in the field of pipe joints, can solve the problems of poor applicability, difficult installation, lack of installation applicability pipe joints, etc., to achieve the effect of wide applicability and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

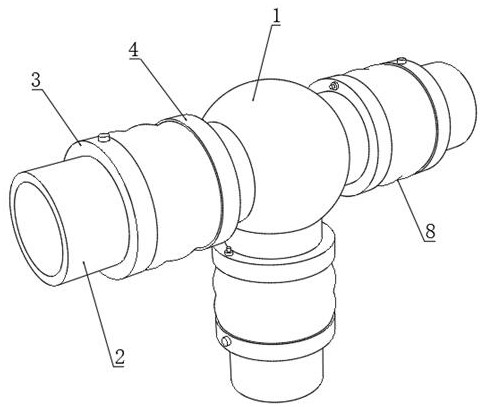

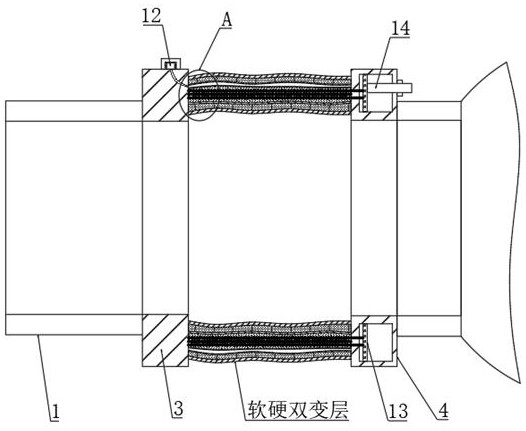

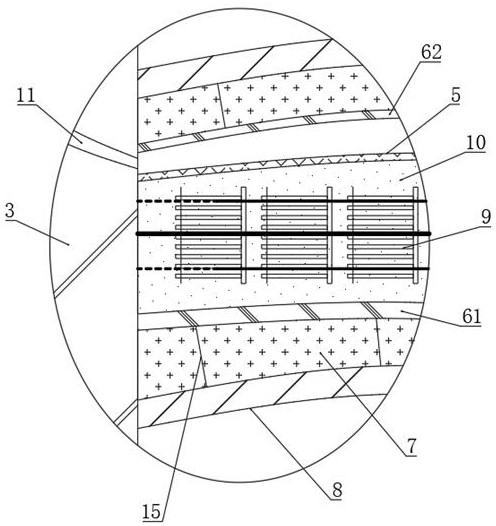

[0041] see figure 1 and figure 2, a highly adaptable stainless steel pipe joint, including a main body 1 and a plurality of connecting pipes 2, the ends of the main body 1 and the connecting pipes 2 close to each other are respectively fixedly connected with a main ring 3 and a secondary ring 4, between the main ring 3 and the secondary ring 4 There are soft and hard double variable layers for fixed connections, see image 3 , the soft and hard dual variable layer includes an outer spacer 62, a heat conduction sleeve 5 and an inner spacer 61 distributed sequentially from the outside to the inside, and the outer side of the outer spacer 62 and the inner side of the inner spacer 61 are provided with a heat insulation sleeve 8, and the heat conduction The sleeve 5, the inner spacer 61, the outer spacer 62 and the heat insulation sleeve 8 are all fixedly connected between the main ring 3 and the auxiliary ring 4, and the space between the inner spacer 61 and the inner heat insul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com