Fixed-length shearing device for household textile thin cloth production

A fixed-length cutting and weaving technology, which is used in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of troublesome cutting operations, affecting the smooth cutting of thin cloth, and unable to cut thin cloth strips at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

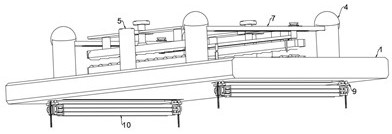

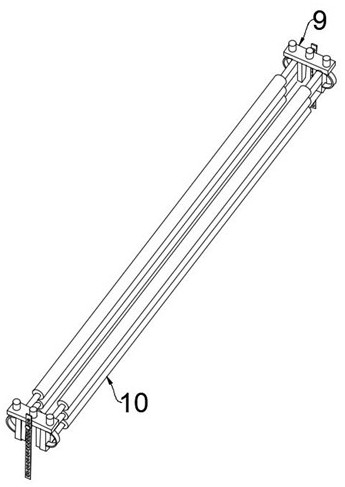

[0032] Refer Figure 1-4 A thin cloth home textile production cut to length apparatus, comprising a processing station fixedly mounted on a plurality of support posts 1, 2, 3 machined with two strip-shaped opening is defined in table 1, table 1 by machining a lower portion of a multi- compression spring 12 is fixedly mounted a plurality of movable plate 9, each of the movable plate 9 by fitting each stopper groove sliding stopper is attached to two slide plates 11;

[0033] It is noteworthy that the above are the following:

[0034] 1, the thin cloth to be cut placed in the upper machining table 1, and both ends are thin cloth strip passes under two ports 3 and La Rujia work table 1, can be cut on the thin cloth both end portions remain in the machining table 1, the thin fabric 1 is located in the lower jaw of processing the workbook tensioning does not affect the normal cloth cutting a thin cloth.

[0035] 2, each sliding plate 11 are fixed on the magnetic plate 13 is mounted, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com