Intermittent chain wheel conveyor line

A conveyor line and sprocket technology, applied in the direction of belt/chain/gear, gear teeth, gear teeth manufacturing devices, etc., can solve problems such as overturning and messing up parts, and achieve the effect of preventing axial displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

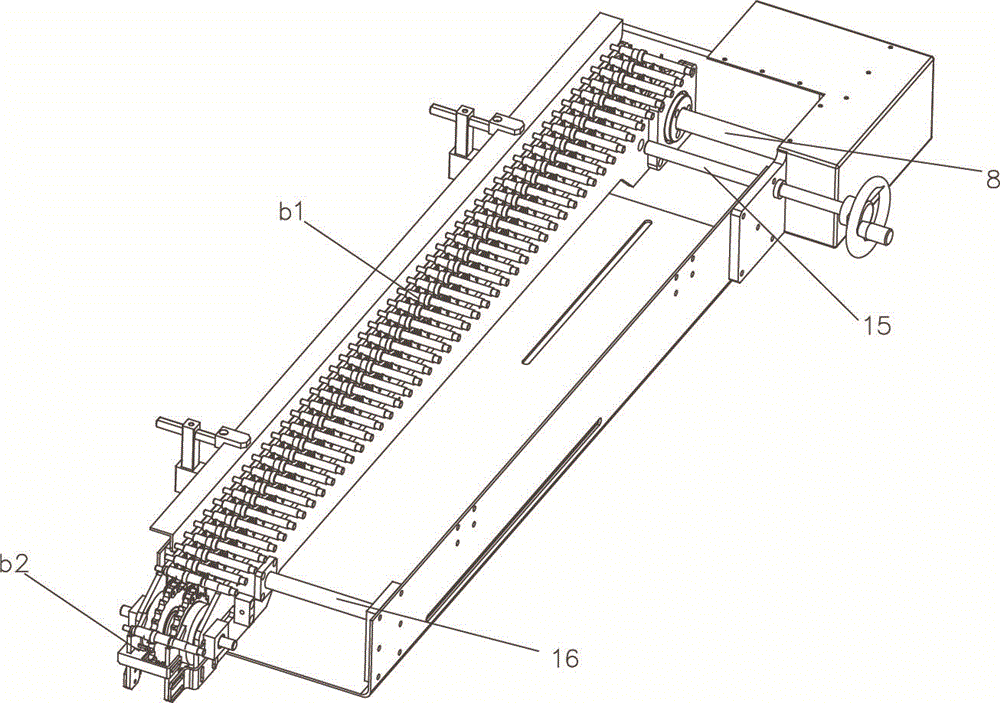

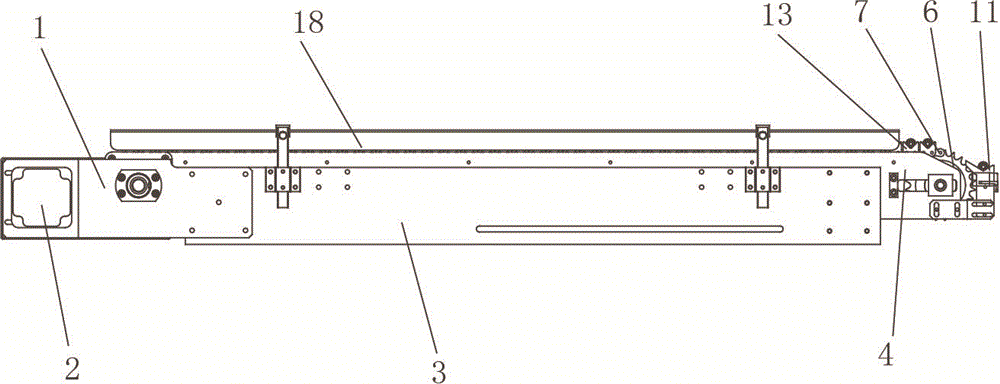

[0018] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1~4 As shown in the figure, marked as follows: aluminum support frame 1, stepper motor 2, bottom groove plate 3, sprocket assembly b1, sprocket support plate 4, driving sprocket 5, driven sprocket 6, chain 7, main wheel Hole 4a, slide bar hole 4b, adjustment slot 4c, rotating shaft 8, timing belt 9, retrieving rack b2, fixed piece 10, positioning V-shaped block 11, card position piece 12, support piece 13, hand wheel 14, adjustment Screw rod 15, sliding rod 16, height block 17, side plate 18, bottom straight plate 19, idler wheel 20, equipment housing a, intermittent sprocket transmission line b, positioning and clamping mechanism c, four-degree-of-freedom manipulator d, beam e, with recycling line f.

[0019] Auxiliary equipment for shaft parts processing includes the equipment shell a, the intermittent sprocket conveyor line b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com