Spinning machine

A technology of spinning machine and bobbin, applied in the field of spinning machine, can solve the problems of hindering spinning station, time-consuming and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In the following description of the alternative exemplary embodiment shown in the figures, the same reference numerals are used for features whose design and / or mode of operation are identical and / or at least similar. If this is not described again in detail, the configuration and / or the effect and mode of operation of the configuration correspond to the aforementioned features.

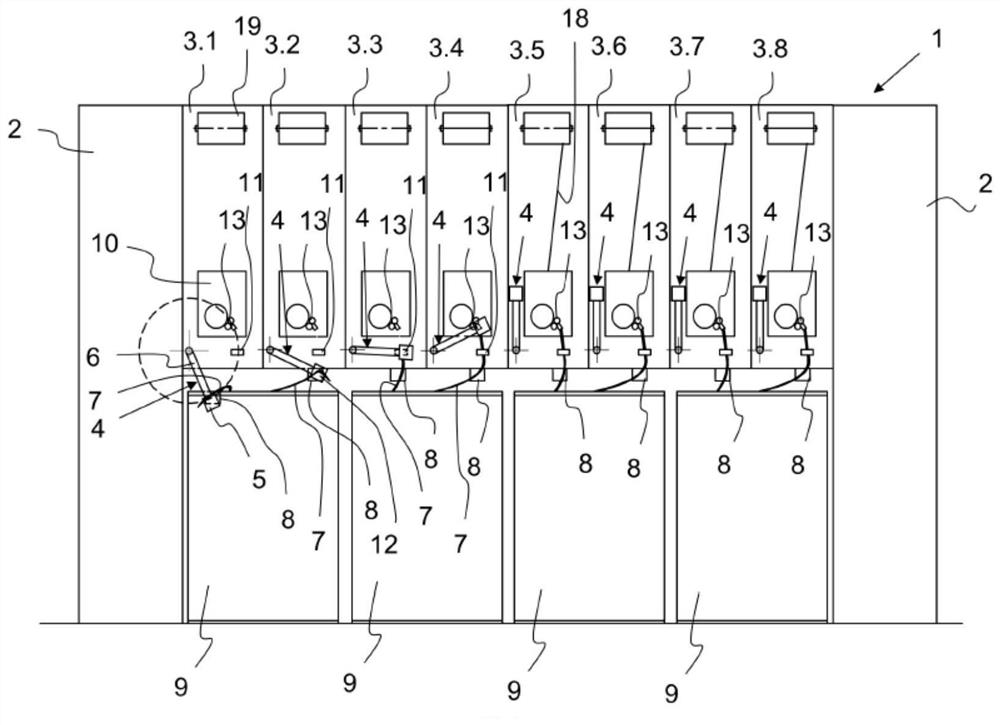

[0036] figure 1 A side view of a spinning machine 1 according to the invention, here an air spinning machine, is shown. Eight spinning stations 3.1 to 3.8 are arranged between the two end supports 2 . Several hundred such spinning stations 3.1 to 3.8 are arranged side by side per machine side in an air spinning machine. The spinning stations are usually subdivided on each machine side into closely arranged individual segments with 8 to 12 spinning stations 3.1 to 3.8 in each case. Each of the spinning stations 3.1 to 3.8 has a spinning box 10 in which a thread bundle 18 is spun and wound on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com