A kind of adhesive layer oil with self-healing characteristics and preparation method thereof

A viscous layer oil and characteristic technology, applied in the direction of adhesives, adhesive types, asphalt material adhesives, etc., to achieve the effects of accelerating solvent volatilization, good road performance, and enhancing bond recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

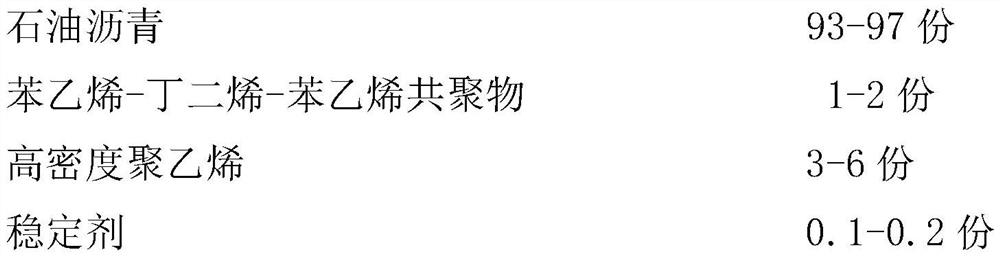

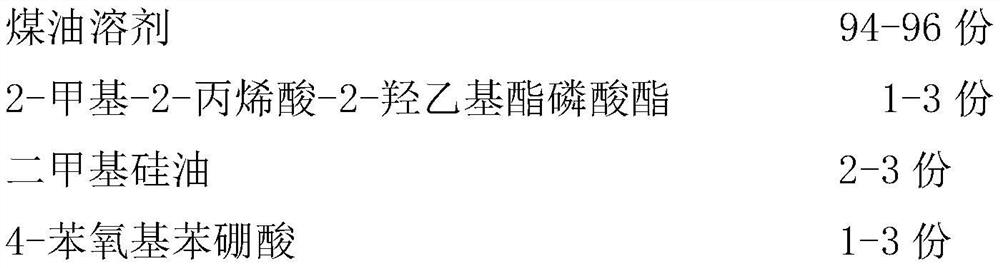

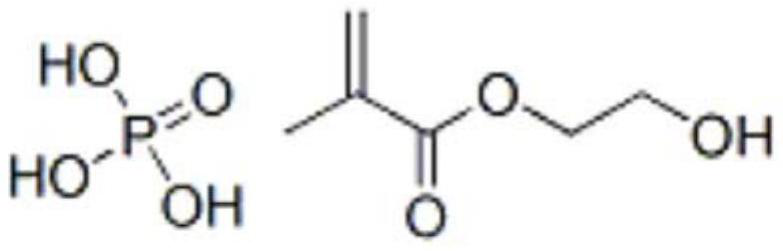

Embodiment 1

[0053] This embodiment is a self-healing viscous oil, which is prepared from the following raw materials by weight: Component 1 includes: 94 parts of petroleum asphalt, 2 parts of styrene-butadiene-styrene copolymer , 4 parts of polyolefin, 0.1 part of stabilizer; Component 2 includes the following parts by weight: 3 parts of dimethyl silicone oil, 95 parts of kerosene solvent, 1 part of 4-phenoxyphenylboronic acid, and 1 part of flame retardant. Component 1 and Component 2 are mixed and diluted in a weight ratio of 1:1.

[0054] The adhesive layer oil with self-healing characteristics was prepared as follows:

[0055] (1) heating petroleum pitch to 170~175 ℃, adding linear styrene-butadiene-styrene copolymer thereinto, and stirring for 60 minutes, and the stirring speed is 600 rev / min;

[0056] (2) in the above-mentioned mixture, add high density polyethylene, and shear and stir for 60 minutes, and the mixer rotating speed is 600 rev / min;

[0057] (3) adding stabilizer sulf...

Embodiment 2

[0061] Component 1 includes: 94 parts of petroleum asphalt, 2 parts of styrene-butadiene-styrene copolymer, 4 parts of polyolefin, and 0.1 part of stabilizer; Component 2 includes the following parts by weight: 3 parts of dimethyl silicone oil , 95 parts of kerosene solvent, 1 part of 4-phenoxybenzeneboronic acid, and 1 part of flame retardant. Component 1 and component 2 are mixed and diluted in a weight ratio of 1:1.5.

[0062] The preparation method of the adhesive layer oil with self-healing characteristics is the same as the preparation method in Example 1.

Embodiment 3

[0064] Component 1 includes: 93 parts of petroleum asphalt, 1 part of styrene-butadiene-styrene copolymer, 6 parts of polyolefin, and 0.1 part of stabilizer; Component 2 includes the following parts by weight: 2 parts of dimethyl silicone oil , 95 parts of kerosene solvent, 2 parts of 4-phenoxybenzeneboronic acid, and 1 part of flame retardant. Component 1 and Component 2 are mixed and diluted in a weight ratio of 1:1.

[0065] The preparation method of the adhesive layer oil with self-healing characteristics is the same as the preparation method in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com