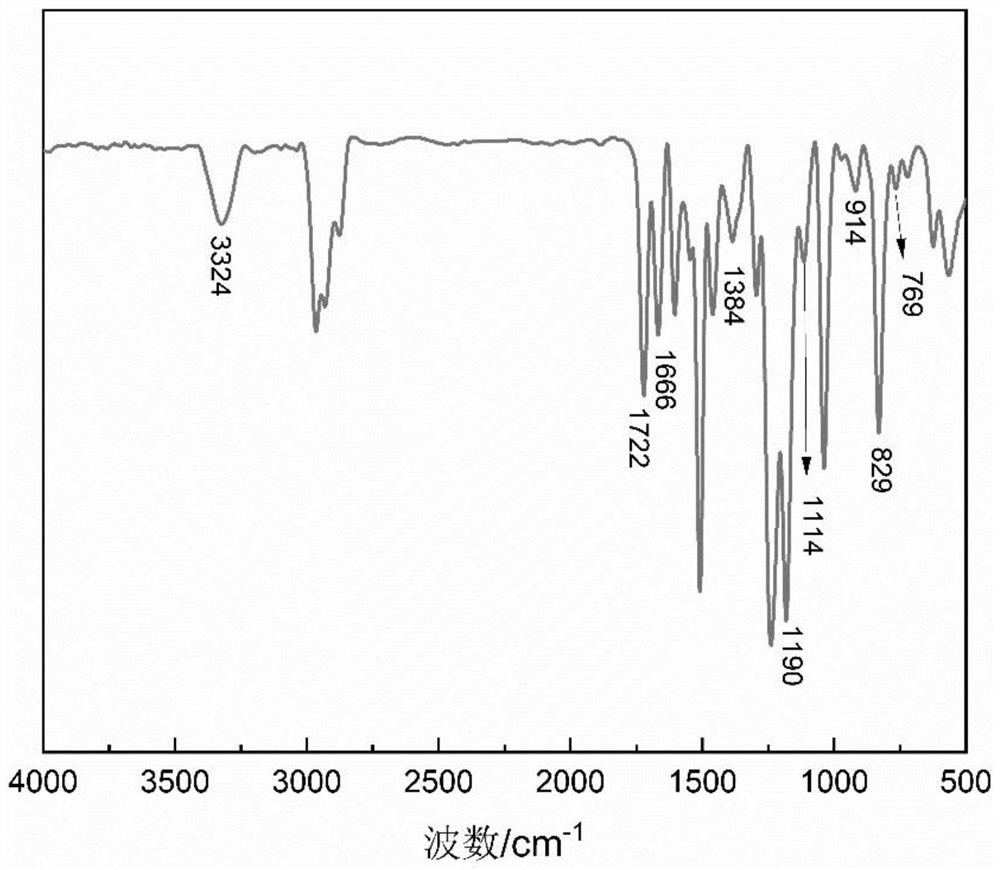

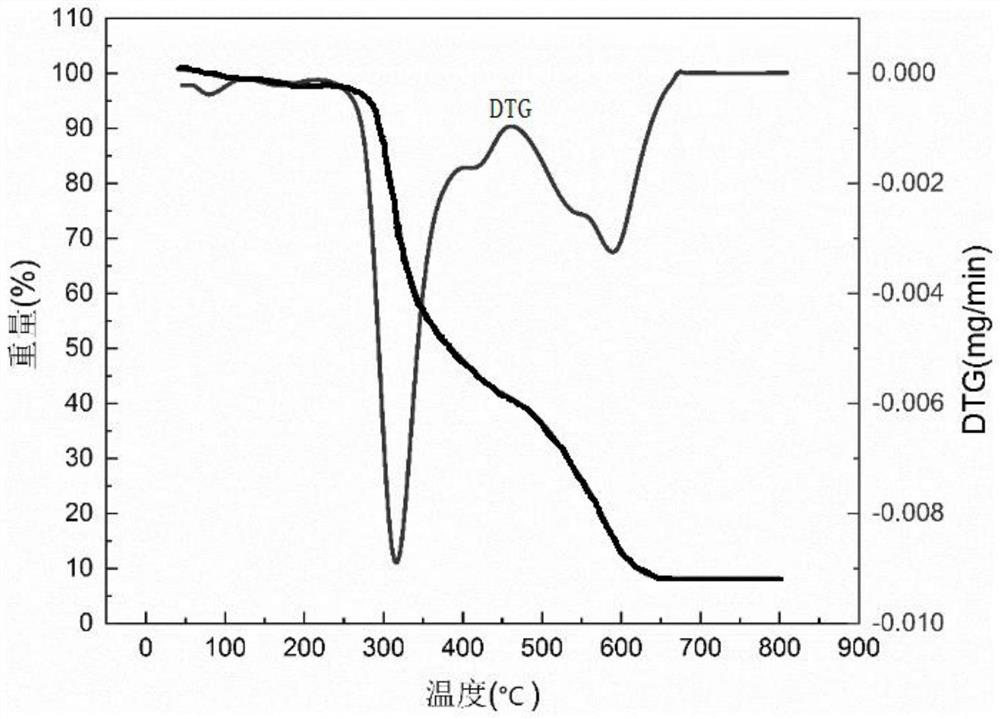

High temperature resistant self-crosslinking waterborne epoxy resin for oil well cement

A water-based epoxy resin, oil well cement technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as high brittleness of cement stone, simplify steps, improve compactness and high brittleness, and avoid construction safety. hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of high temperature resistant self-crosslinking water-based epoxy resin for oil well cement, the steps are as follows:

[0030] (1) 105g of epoxy resin E44 is dissolved in 135g of N,N-dimethylformamide, transferred to a three-necked flask with a condenser tube and a constant pressure dropping funnel, fed with nitrogen, stirred by a magnetic stirrer and Heating to 85°C;

[0031] (2) Using 4g of benzoyl peroxide as an initiator, dissolve benzoyl peroxide in 11g of acetone, then add the acetone solution dropwise into a three-necked flask, raise the temperature of the system to 95°C, and react at a constant temperature for 30min;

[0032] (3) 45g of 2-acrylamido-2-methylpropanesulfonic acid (AMPS) and 5g of acrylamide (AM) were dissolved in 40g of water to form a mixed aqueous solution; then the mixed aqueous solution was slowly added to a three-necked flask and kept at a constant temperature Reaction 4h;

[0033] (4) After the reaction, the solvent w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com