Cable elevator and working method thereof

A lifter and cable technology, used in the field of water pump testing, can solve problems such as leakage, banning, slipping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

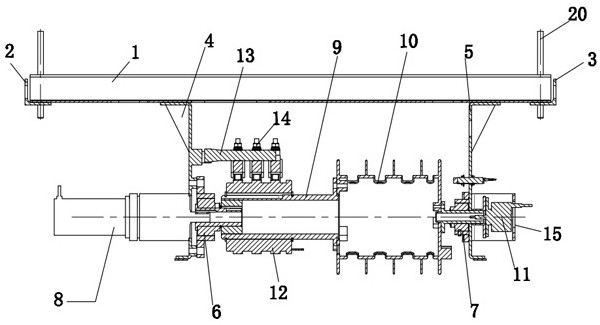

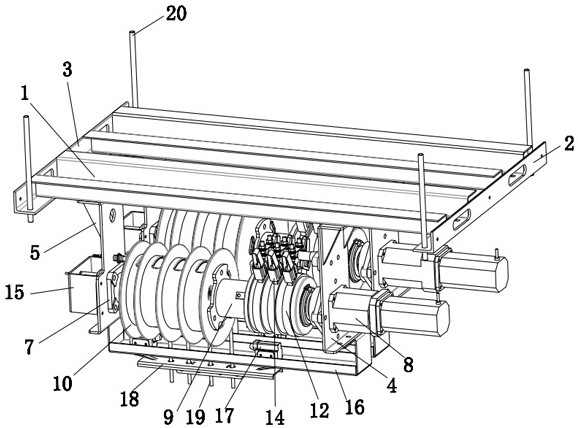

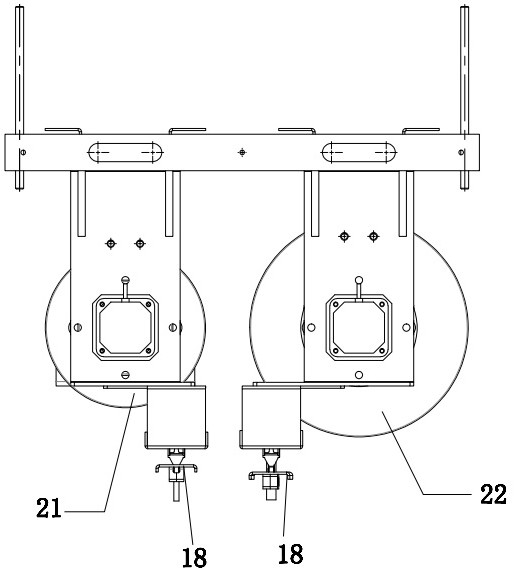

[0021] see Figure 1 to Figure 3 The cable lifter in this embodiment mainly includes a main beam 1, a left longitudinal beam 2, a right longitudinal beam 3, a left suspension 4, a right suspension 5, a left bearing seat 6, a right bearing seat 7, a servo motor 8, a main shaft 9, a winding Wire reel 10, electric slip ring 11, three-phase electric slip ring 12 and lower beam 16, left longitudinal beam 2 and right longitudinal beam 3 are respectively fixed at both ends of main beam 1, and left suspension is installed under the main beam 1 4. Right suspension 5, left suspension 4 and right suspension 5 are respectively equipped with left bearing seat 6, right bearing 7, servo motor 8 is fixed on left suspension 4, and the motor shaft of servo motor 8 passes through the left The bearing seat 6 is connected with the main shaft 9, the winding reel 10, the right bearing seat 7, and the electric slip ring 11 in turn. The three-phase electric slip ring 12 is installed on the main shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com