Synchronous tightening device and method for fuel tank drawstring bolts

A bolt and tie technology, which is applied in the field of synchronous tightening device for pull tie bolts in fuel tanks, can solve problems affecting the firmness of tightening, low work efficiency, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is attached Figure 1-5 The present invention is described in further detail.

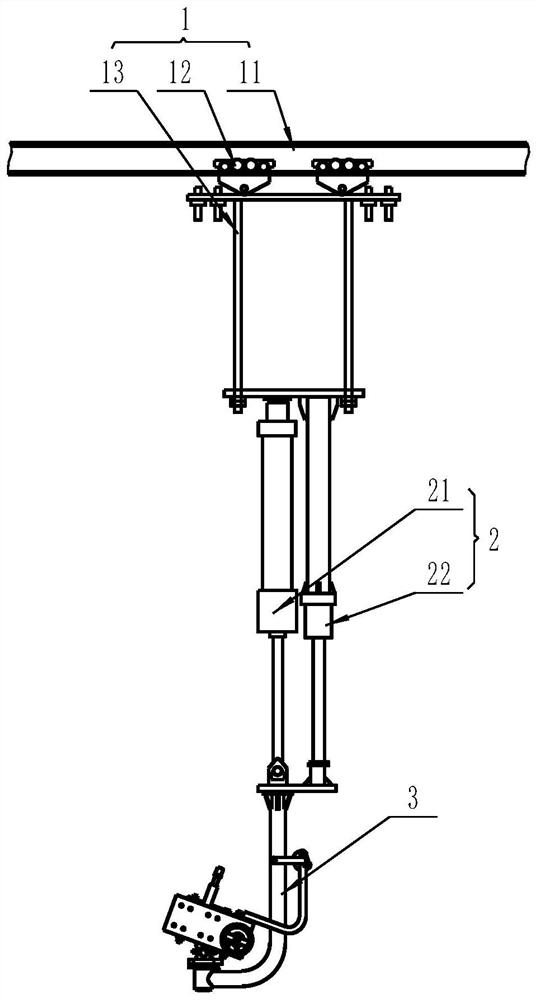

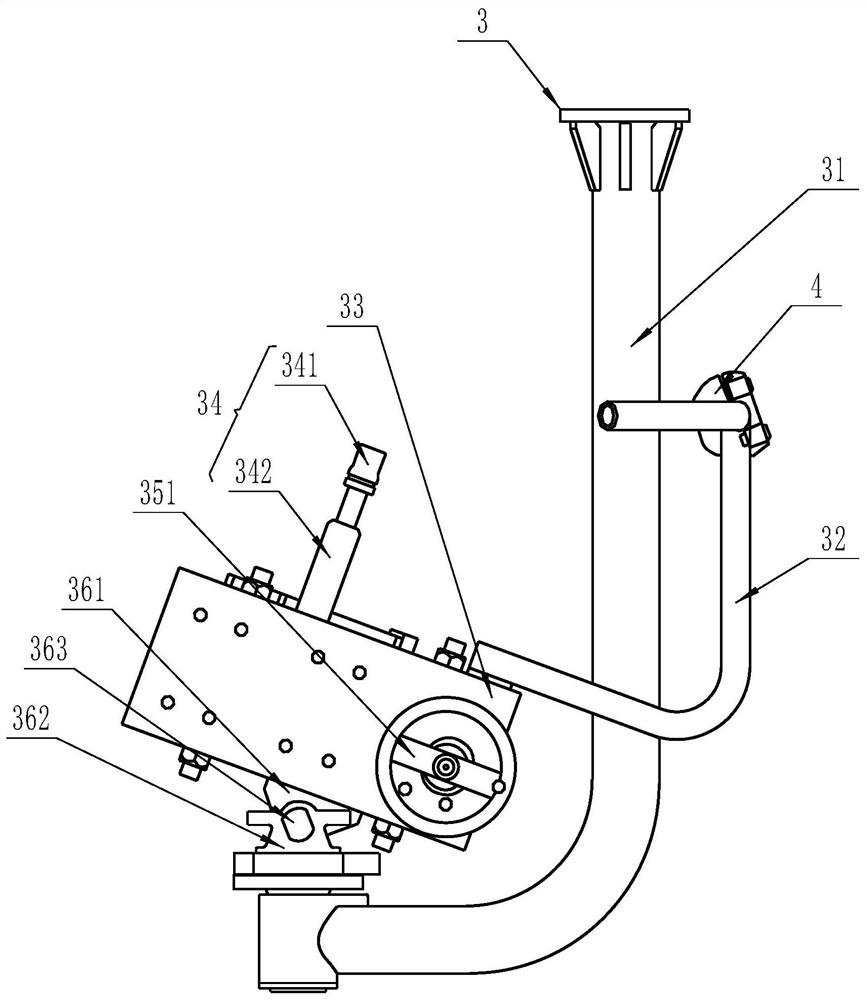

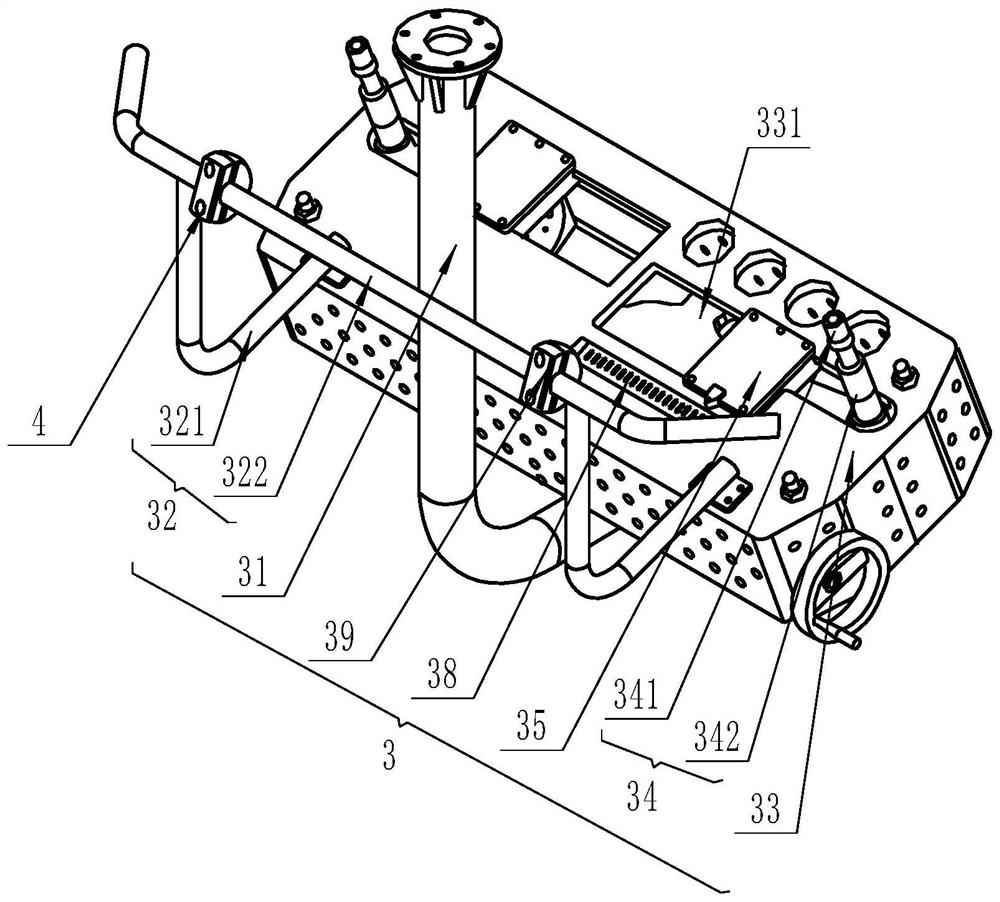

[0037] The embodiment of the invention discloses a device and a method for synchronously tightening fuel tank tie bolts. refer to Figure 1-5, a fuel tank tie bolt synchronous tightening device, including a moving part 1, a lifting part 2, a tightening part 3, and a remote control lifting button 4, the lifting part 2 is fixed below the moving part 1, and the tightening part 3 is fixed on Below the lifting part 2 , the remote control lifting button 4 is installed on the tightening part 3 , and the lifting part 2 is electrically connected with the remote control lifting button 4 .

[0038] refer to figure 1 , above-mentioned moving part 1 comprises rail 11, traveling wheel 12, traveling frame 13, and described rail 11 is fixed on indoor top, and described traveling frame 13 is provided with a plurality of traveling wheels 12 that can walk on traveling frame 13. The lifting pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com