Winding head of spinning machine

A technology of machine winding and spinning, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc. It can solve the problem of difficult control of the winding distance of silk thread and the tightness of silk winding, and achieve the effect of ensuring the winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

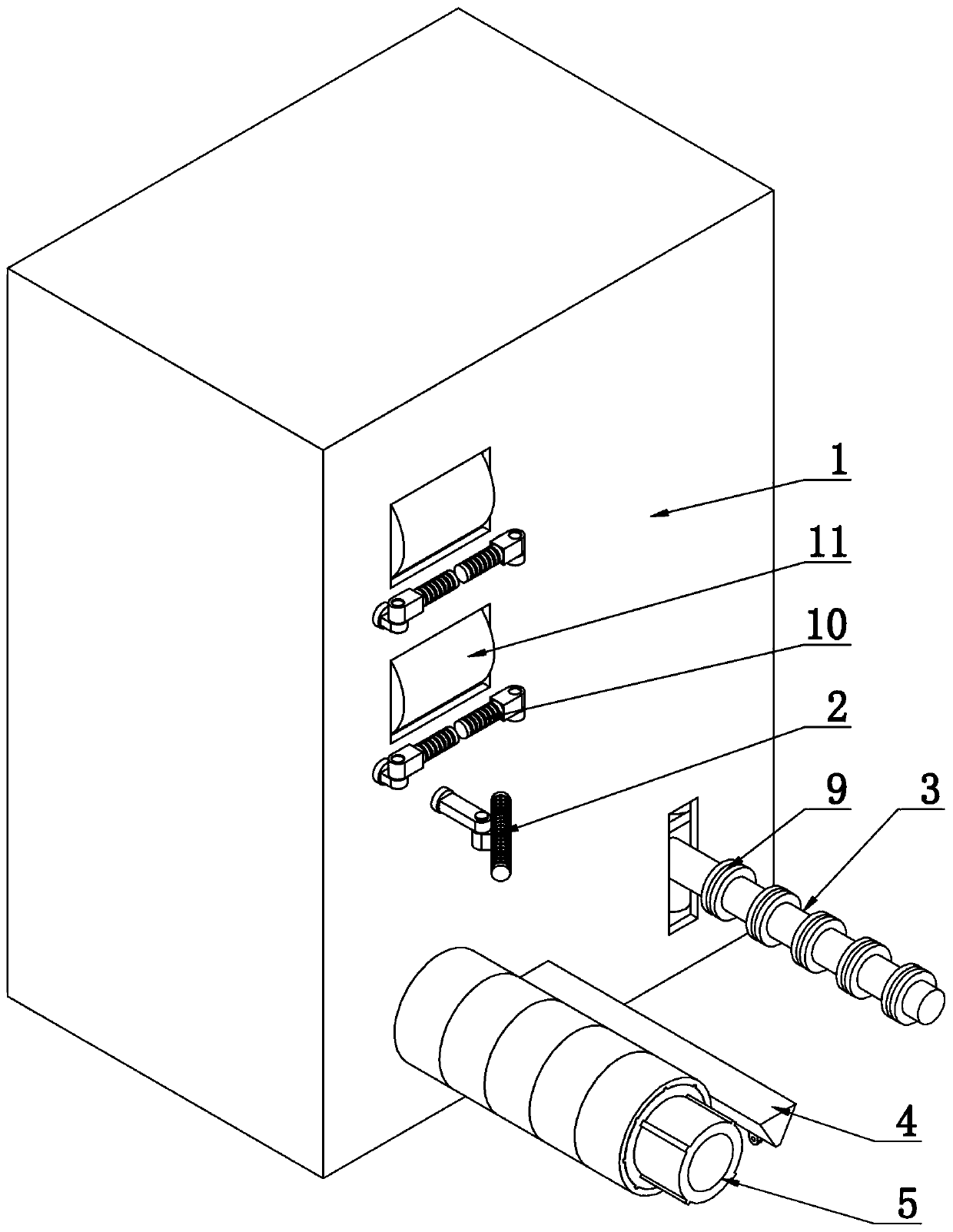

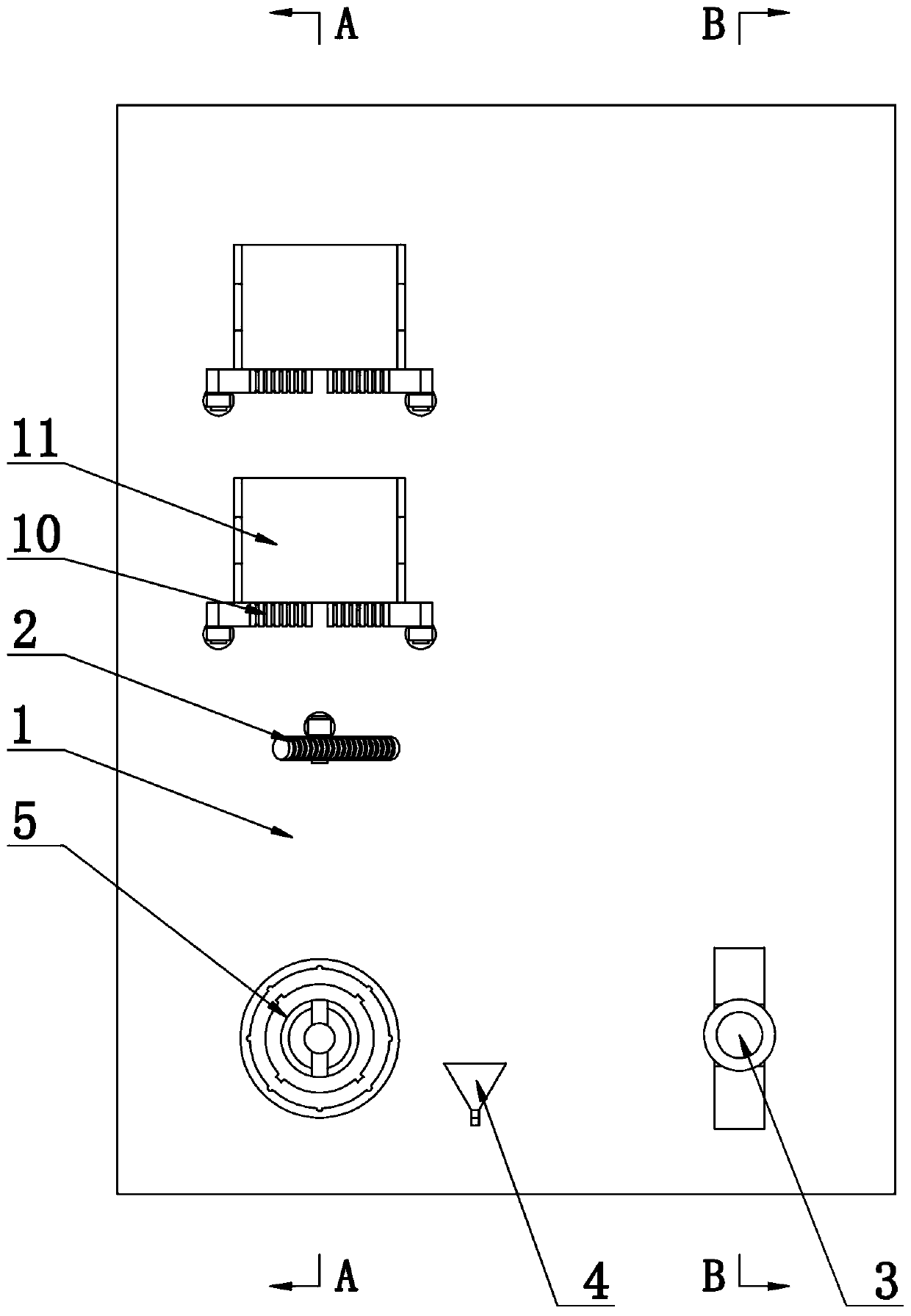

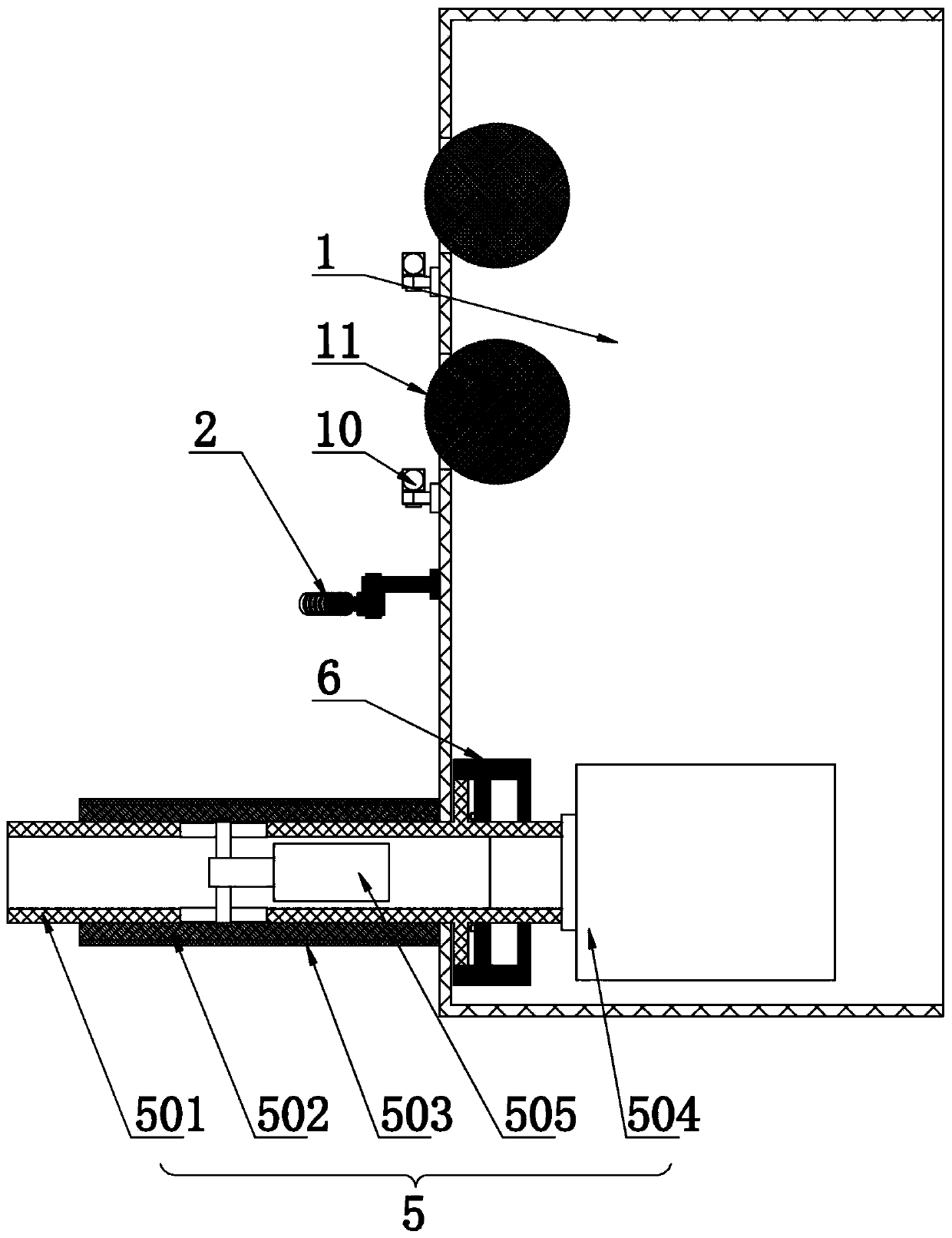

[0034] Such as Figure 1-11 As shown, a winding head of a spinning machine includes a box body 1, a steering rod 2, a guide rod 3, a positioning rod 4 and a winding drum 5, a steering rod 2, a guiding rod 3, a positioning rod 4 and a winding drum 5 They are all arranged on the end face of the box body 1, the winding drum 5 is located below the steering rod 2, the guide rod 3 and the positioning rod 4 are located on one side of the winding drum 5, and the winding drum 5 includes a rolling drum 501, a traverse drum 502, The fixed sleeve 503, the rotating motor 504 and the telescopic motor 505, the rolling cylinder 501, the traverse cylinder 502 and the fixed sleeve 503 are hollow cylinders coaxially fitted from the inside to the outside, one end of the rotating cylinder is rotationally connected with the box body 1, and the other end is extended. Out of the box 1, the traversing cylinder 502 slides and fits on the rolling cylinder 501 along the length direction of the rolling cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com