Double-cooling type energy-saving compression heat drying machine and drying method

A technology of compression heat and double cooling, applied in the field of pressure swing adsorption, which can solve the problems of small effective gas supply, long working cycle, and large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

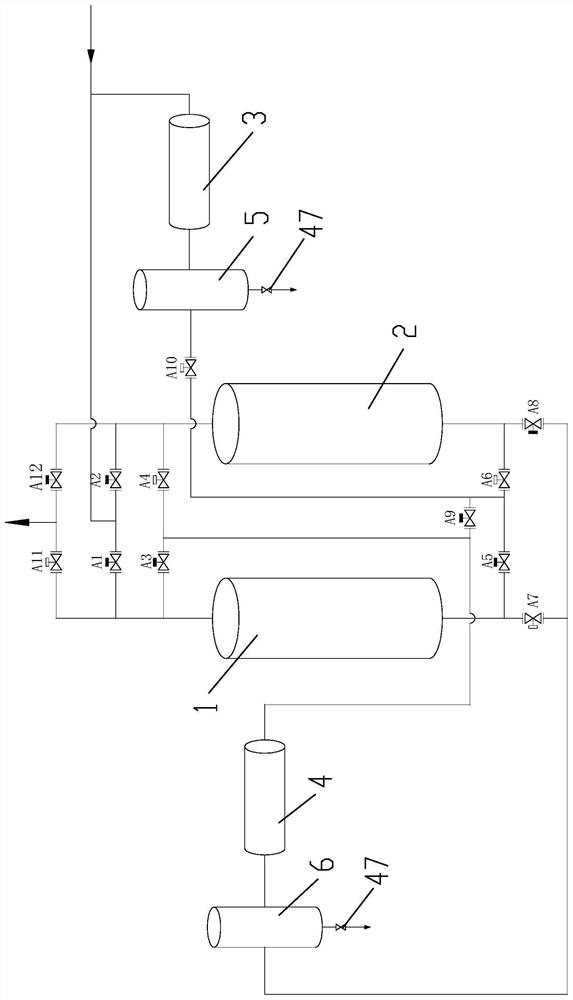

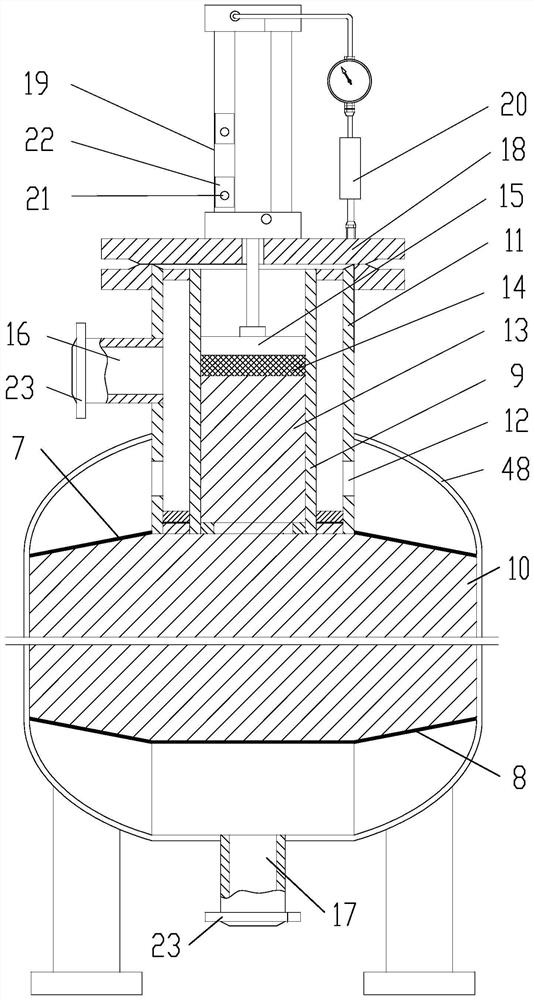

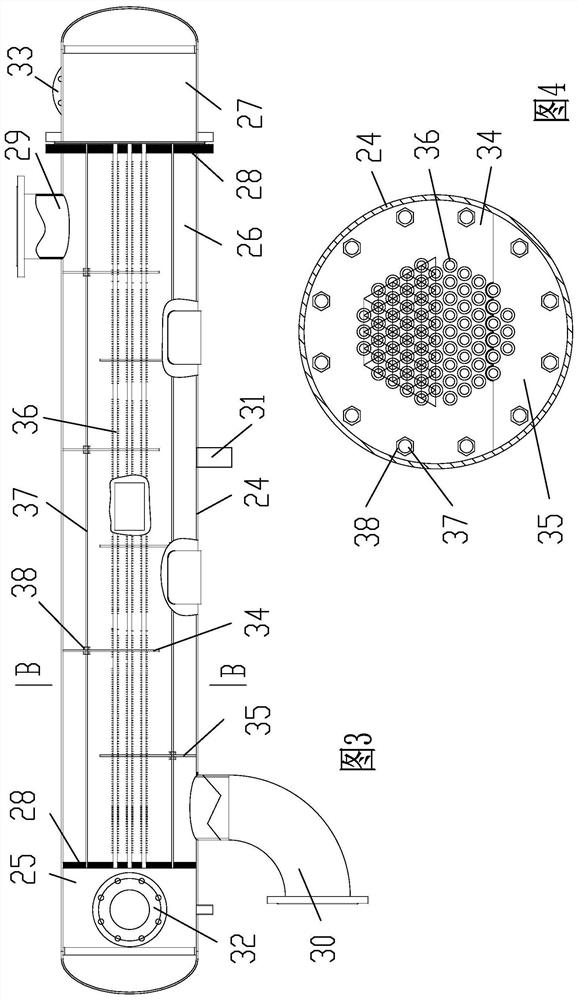

[0023] as attached figure 1 to attach Figure 5 Shown: a double-cooling energy-saving compression heat dryer, including: two drying towers with upper air pipe 16 and lower air pipe 17, valve A1, valve A3, Valve A11, valve A2, valve A4, and valve A12 connected at one end to the upper gas pipe 16 of the second drying tower 2, valve A5 and valve A7 connected to the lower gas pipe 17 of the first drying tower 1 at one end, and connected to the second drying tower at one end Valve A6 and valve A8 connected to the lower air pipe 17 of 2, valve A9 and valve A10 connected at one end to valve A5 and the other end of valve A6, and the inlet is connected to the other end of valve A1 and valve A2 to form the first cooler 3 of humid air inlet , the first separator 5 communicated with the outlet of the first cooler 3 and the other end of the valve A10, the second cooler 4 whose in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com