Method for fastening a rail of an elevator system in an elevator shaft

A technology for elevator shafts and guide rails, which is applied in the direction of mechanical equipment, fixed rails, and friction-clamped detachable fasteners. It can solve problems such as loss of function of elastic materials, overload of elastic materials, and application of screws to achieve length compensation. performance, reliable clamping force, and the effect of reducing the range of variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

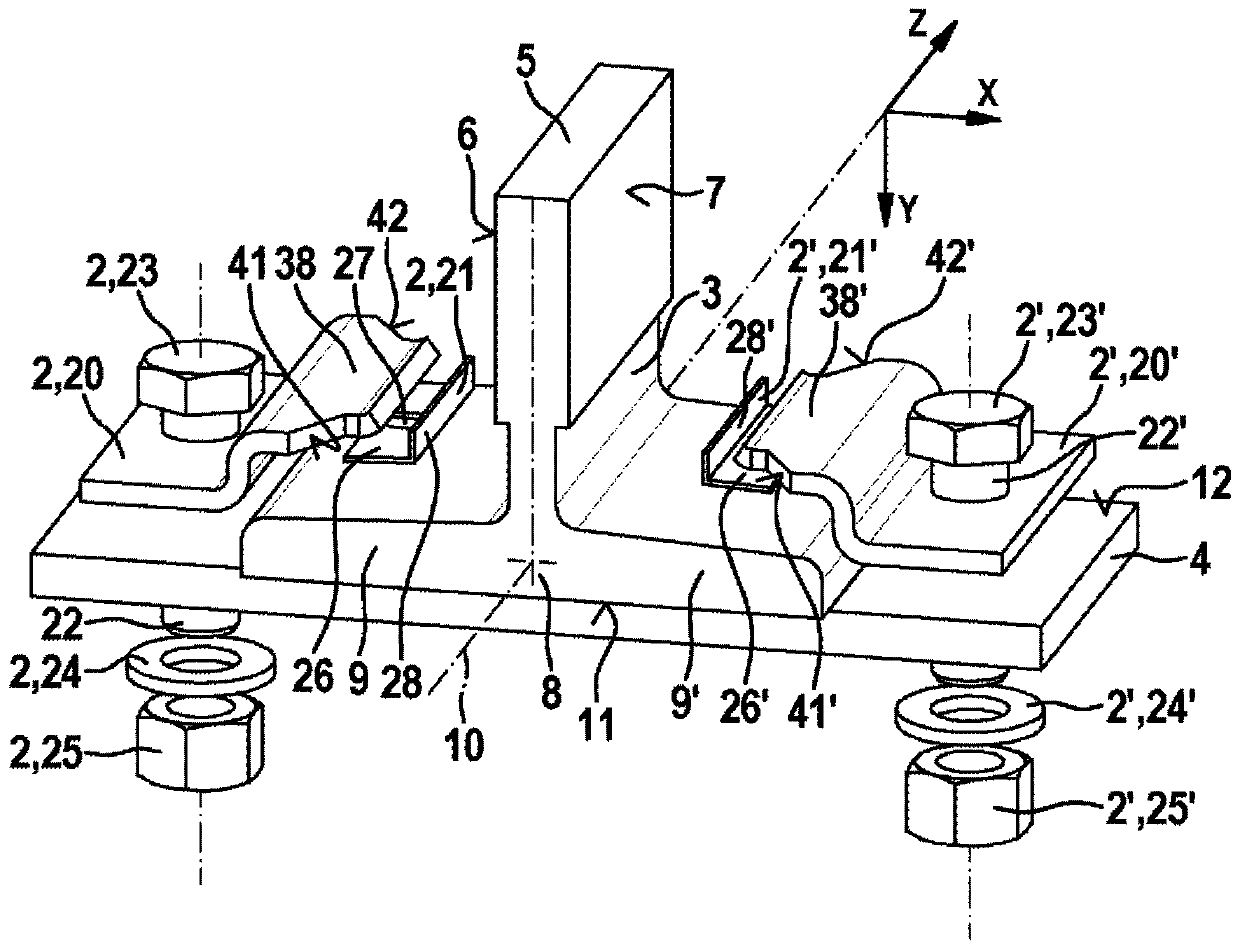

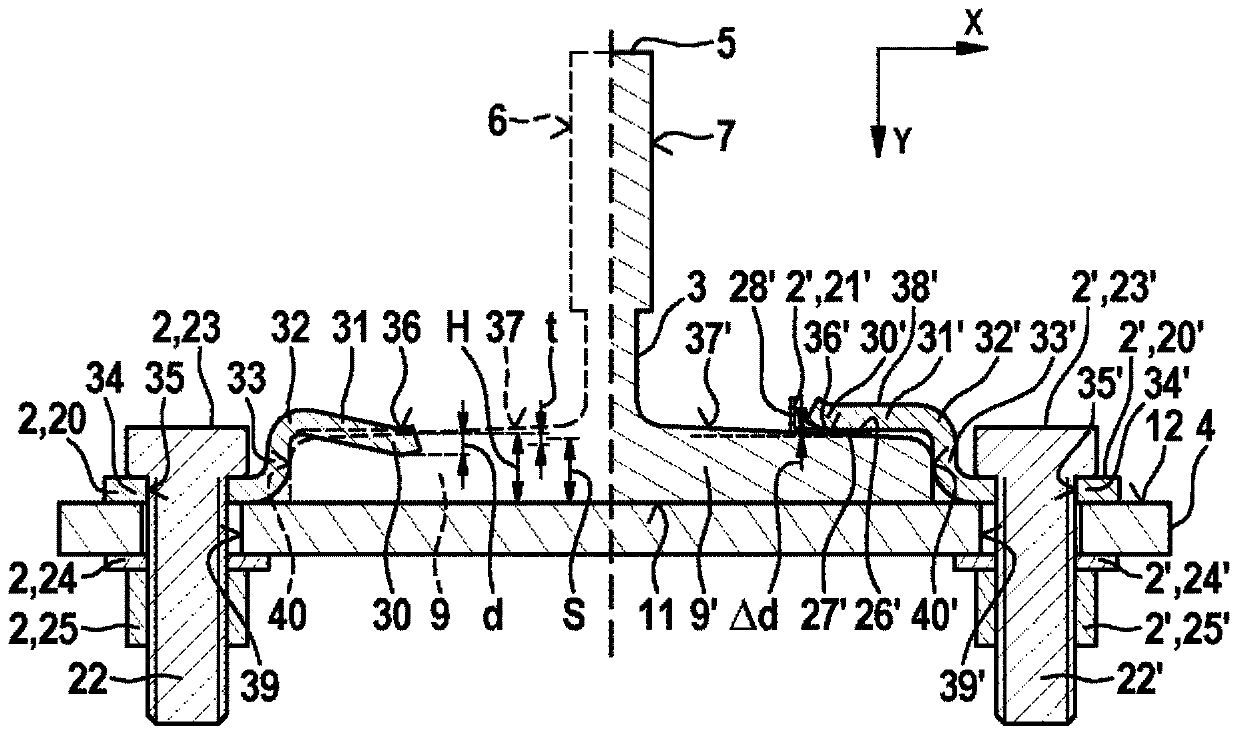

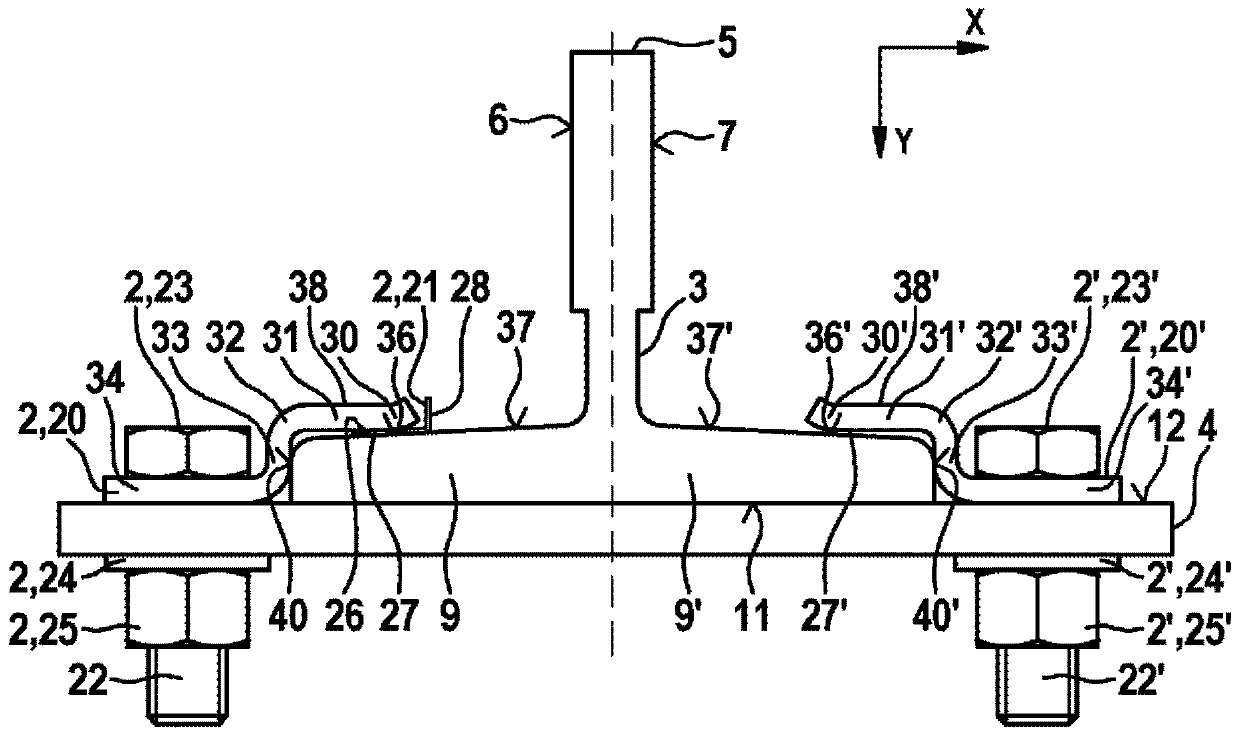

[0039] figure 1 shows the elevator installation 1 ( Figure 4 ) of the guide rail 3, which is fixed on the support body 4 by the clamping set 2 and the clamping set 2', for explaining the first embodiment. The guide rail 3 has a guide rail head 5 with guide surfaces 6 , 7 . Furthermore, the guide rail 3 has a guide rail foot 8 with sides 9, 9'. as well Figure 4 As shown, the guide rail 3 extends along its extension 10 through the elevator shaft 11 when the guide rail 3 is installed. For the sake of explanation, a direction Z is defined here along the extension 10 . The underside 11 of the rail foot 8 is placed on the upper side 12 of the carrier 4 during installation. In this case, the degree of freedom in the direction Y is limited by the upper side 12 . With respect to the right-handed coordinate system, there is also a direction X.

[0040] In the fixed state, the guide rail 3 should be displaceable relative to the support body 4 in and against the direction Z in or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com